1. Setup and Installation

Before operating the VEVOR Plastic Shredder Crusher, ensure proper setup and installation according to these guidelines.

1.1 Power Connection

This product operates on a 220V three-phase four-wire system. It does not come with a plug and requires professional wiring for use. Ensure all electrical connections comply with local codes and safety standards.

1.2 Machine Placement and Mobility

The unit is equipped with four wheels: two fixed front wheels and two rear 360-degree swivel casters. This design allows for easy movement and positioning of the machine. Place the shredder on a stable, level surface in a well-ventilated area.

2. Operating Instructions

Follow these steps for safe and effective operation of your plastic shredder.

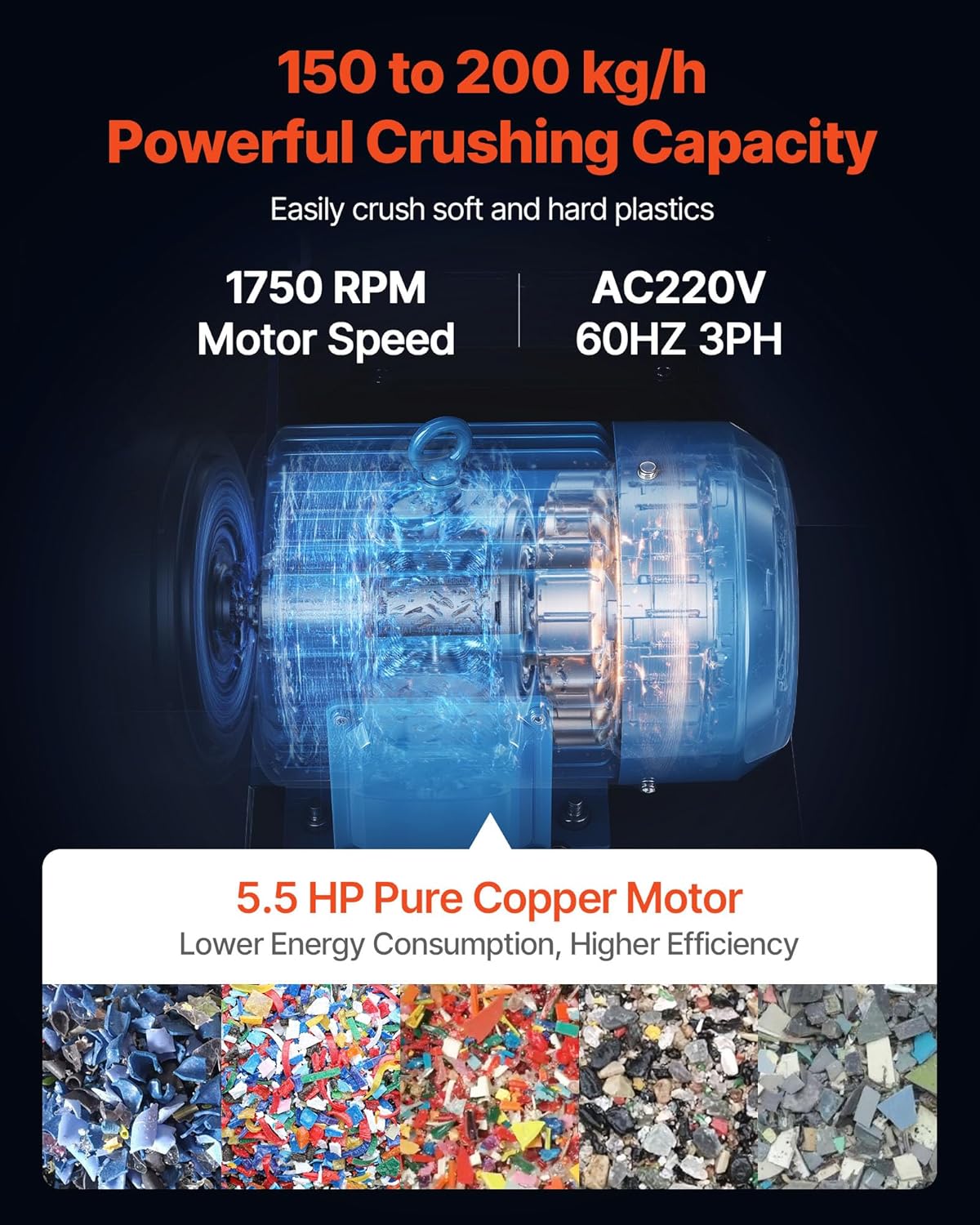

2.1 Material Loading and Crushing Capacity

The shredder features a 5.5HP (4.0KW) pure copper motor with a 1750 RPM motor speed and an 8mm mesh size, providing a crushing capacity of 150-200 kg/h. It is designed to efficiently shred a wide range of materials including PC, PVC, ABS, PET, EPS, PU, HDPE, rubber, leaves, wood, and nylon. Use the convenient feed button for faster material loading and smoother feeding.

2.2 Blade System

The shredder is equipped with 8 SKD-11 alloy steel blades (6 rotating and 2 fixed). These blades are designed for high hardness and impact resistance, ensuring efficient crushing. The blades can be removed, polished, and reused when dull.

2.3 Safety Features

The machine incorporates dual safety protection for secure operation:

- Overload Protection: Automatic shutdown in case of motor overload.

- Power Interlock Protection: Automatic power cutoff when the lid is opened during operation.

2.4 Noise Reduction

The shredder features a double-layer soundproof design, consisting of double-layer steel plates and soundproofing cotton. This design minimizes noise and vibrations during operation. For optimal long-term ear protection, wearing earmuffs is highly recommended.

2.5 Video Demonstrations

Plastic Bottle Shredding Demonstration

Video: This video demonstrates the VEVOR Plastic Shredder Crusher in action, showing how plastic bottles are fed into the machine and processed into smaller granules. It highlights the efficiency of the shredding process.

Plastic Cup Shredding Demonstration

Video: This video showcases the shredder's capability to process plastic cups, illustrating the transformation of larger plastic items into uniform granules suitable for recycling or further processing.

3. Maintenance

Regular maintenance ensures the longevity and optimal performance of your shredder.

3.1 Blade Care

The SKD-11 blades are designed to be removed, polished, and reused. Regularly inspect blades for sharpness and damage. If dull, remove and sharpen them. Note: Avoid shredding glass or metal, as this may damage the blades and the machine.

3.2 Cleaning and Inspection

The machine features manually removable lock nuts for quick disassembly, facilitating easy cleaning and regular maintenance. After each use, or as needed, clean out any accumulated material from the crushing chamber and the extended drawer. Ensure all safety mechanisms are free from debris and functioning correctly.

4. Troubleshooting

This section provides guidance for common operational issues.

4.1 Machine Not Starting

- Ensure the power supply is correctly connected and active (220V three-phase).

- Check if the lid is securely closed. The power interlock protection prevents operation if the lid is open.

- Verify that the emergency stop button, if present, is not engaged.

4.2 Reduced Crushing Performance

- Inspect the blades for dullness or damage. Sharpen or replace as necessary.

- Ensure the material being fed is within the recommended types and sizes.

- Check for any blockages in the feed inlet or crushing chamber.

4.3 Machine Stops During Operation

- This may indicate activation of the overload protection. Turn off the machine, clear any excessive material, and allow the motor to cool before restarting.

- Check for any foreign objects (e.g., metal, glass) that may have entered the crushing chamber and caused a jam.

5. Specifications

| Feature | Detail |

|---|---|

| Model Number | 250 |

| Motor Power | 5.5HP / 4.0KW (Pure Copper Motor) |

| Motor Speed | 1750 RPM |

| Voltage | AC220V 60Hz 3-Phase |

| Crushing Capacity | 150-200 kg/h |

| Mesh Size | 8 mm |

| Blades | 8 Pcs SKD-11 (6 Rotating + 2 Fixed) |

| Noise Reduction | Double-Layer Steel Plates + Soundproofing Cotton |

| Product Dimensions (L x W x H) | 36.81 x 26.38 x 40.94 inches (935 x 670 x 1040 mm) |

| Item Weight | 503 pounds (228 kg) |

6. Warranty and Support

VEVOR is committed to providing quality products and customer satisfaction.

- Returns: This product is eligible for 30-day easy returns. Please refer to the retailer's return policy for detailed instructions.

- Customer Support: For any questions, technical assistance, or support needs, please contact VEVOR customer service.