1. Introduction

This manual provides essential information for the safe and efficient operation, maintenance, and troubleshooting of your General Pump EZ4040G Series 44 Pressure Washer Pump. Please read this manual thoroughly before installation or operation to ensure proper use and to prevent damage or injury.

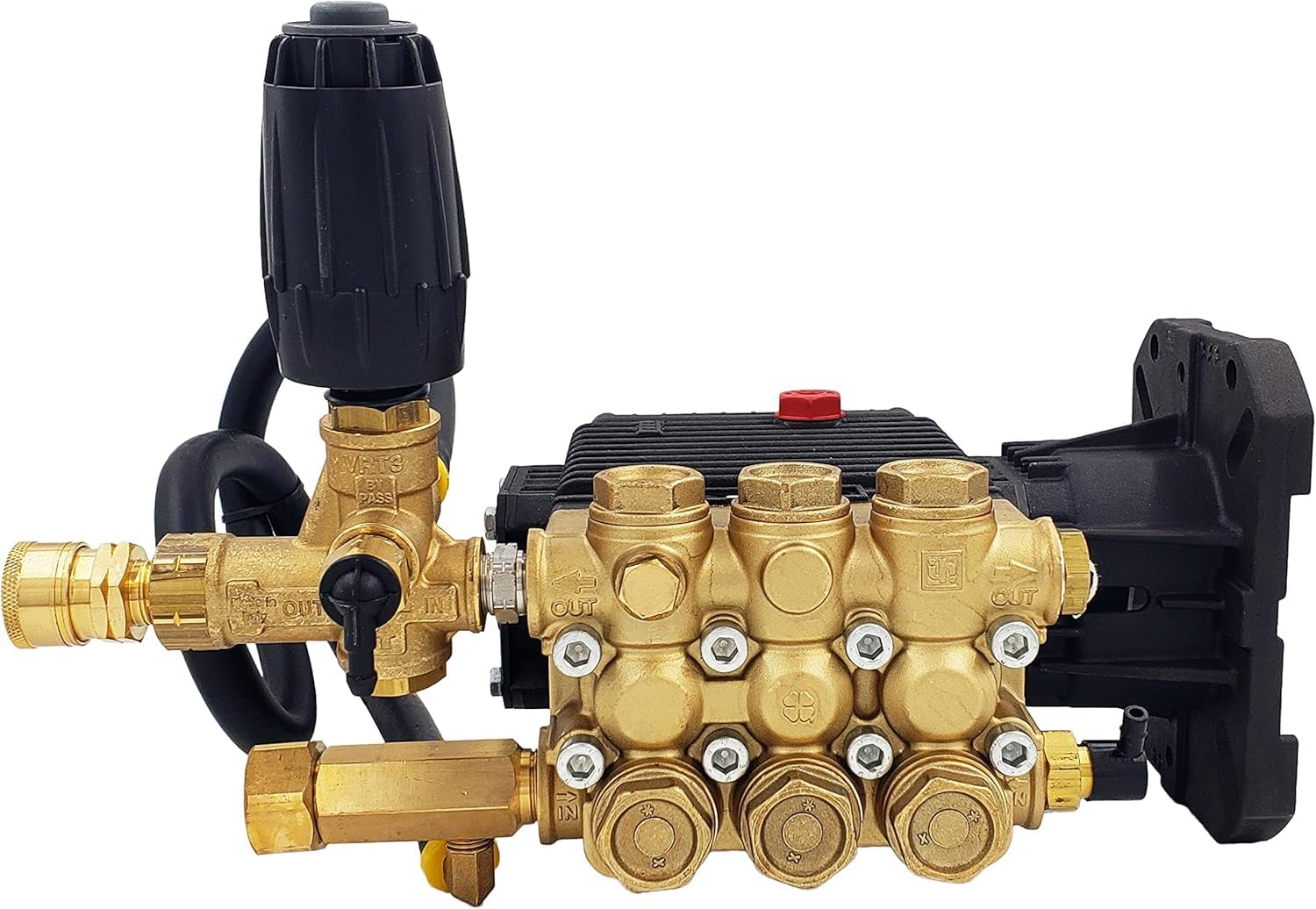

The General Pump EZ4040G Series 44 is a high-performance triplex plunger pump designed for demanding pressure washing applications, capable of delivering up to 4000 PSI and 4 GPM. This fully plumbed unit includes a bypass hose, inlet filter, thermal relief valve, and unloader valve for integrated functionality.

2. Safety Information

WARNING: Failure to follow these safety instructions could result in serious injury or property damage.

- Always wear appropriate personal protective equipment (PPE), including eye protection, hearing protection, and protective clothing, when operating or servicing the pump.

- Ensure the pump is securely mounted and stable before operation.

- Never operate the pump without a proper water supply. Running dry can cause severe damage.

- Do not direct the high-pressure spray at people, animals, electrical equipment, or the pump itself.

- Verify all connections are tight and leak-free before starting the pump.

- Relieve all system pressure before disconnecting hoses or performing maintenance.

- Keep children and pets away from the operating area.

- Use only genuine General Pump replacement parts.

- If the pump is gasoline-powered, ensure adequate ventilation to prevent carbon monoxide poisoning.

3. Components Overview

The General Pump EZ4040G Series 44 pump is a robust unit with several key components:

- Pump Head (Brass): Contains the plungers, valves, and seals responsible for pressurizing water.

- Crankcase (Black): Houses the crankshaft, connecting rods, and bearings.

- Unloader Valve: Regulates system pressure and diverts water back to the inlet when the spray gun trigger is released.

- Thermal Relief Valve: Protects the pump from overheating by releasing hot water if the internal temperature exceeds a safe limit.

- Inlet Filter: Prevents debris from entering the pump, protecting internal components.

- Bypass Hose: Connects the unloader valve to the pump inlet, allowing water recirculation during bypass mode.

- Inlet Port: Connection point for the water supply hose.

- Outlet Port: Connection point for the high-pressure hose.

4. Setup and Installation

Proper installation is crucial for the performance and longevity of your pump.

4.1 Mounting the Pump

- Ensure the mounting surface is flat, stable, and capable of supporting the pump's weight.

- Align the pump's mounting flange with the engine's drive shaft.

- Secure the pump using appropriate bolts and washers. The pump typically requires two large bolts and two smaller bolts for secure attachment to an engine, as noted in user feedback.

- Verify that the pump is level and there is no strain on the drive shaft connection.

4.2 Water Inlet Connection

- Connect a garden hose (minimum 5/8 inch diameter) from your water source to the pump's inlet port.

- Ensure the inlet filter is clean and properly installed to prevent debris from entering the pump.

- The water supply must provide a minimum of 4 GPM to match the pump's maximum flow rate. Insufficient water supply can lead to cavitation and pump damage.

- Use thread sealant tape on all threaded connections to prevent leaks.

4.3 High-Pressure Outlet Connection

- Connect the high-pressure hose to the pump's outlet port.

- Ensure the hose is rated for the maximum pressure of the pump (4000 PSI).

- Connect the other end of the high-pressure hose to your spray gun or other pressure washing accessories.

- Tighten all connections securely.

4.4 Bypass Hose and Unloader Valve

- The bypass hose is pre-plumbed to connect the unloader valve to the pump inlet. Verify this connection is secure.

- The unloader valve is factory-set for optimal performance. Do not attempt to adjust it unless you are a qualified technician. Improper adjustment can lead to pump damage or unsafe operation.

4.5 Thermal Relief Valve

- The thermal relief valve is pre-installed. It is a safety device that releases hot water if the pump recirculates water for too long without the spray gun trigger being engaged, preventing internal damage from excessive heat.

- Ensure the discharge path for the thermal relief valve is clear and directed away from people or sensitive equipment.

5. Operating Instructions

5.1 Pre-Operation Checklist

- Check pump oil level. Ensure it is within the recommended range.

- Inspect all hoses for kinks, cuts, or damage.

- Verify all connections are tight.

- Ensure the water supply is turned on and flowing freely to the pump.

- Check that the inlet filter is clean.

- Confirm the spray gun is equipped with the correct nozzle for the task.

5.2 Starting the Pump

- With the water supply connected and turned on, squeeze the spray gun trigger to purge air from the system until a steady stream of water emerges.

- Start the engine (if applicable) according to its manufacturer's instructions.

- Once the engine is running, the pump will begin to pressurize the water.

- Release the spray gun trigger to allow the unloader valve to bypass water.

5.3 During Operation

- Maintain a constant water supply to the pump.

- Avoid prolonged operation in bypass mode (with the spray gun trigger released) to prevent water overheating and activation of the thermal relief valve. If extended bypass is necessary, periodically squeeze the trigger to introduce cool water or shut down the engine.

- Monitor for unusual noises, leaks, or vibrations. If any occur, shut down the pump immediately and investigate.

5.4 Shutting Down

- Turn off the engine.

- Turn off the water supply.

- Squeeze the spray gun trigger to release any remaining pressure in the system.

- Disconnect hoses.

5.5 Winterization (for cold climates)

- Drain all water from the pump and hoses to prevent freezing and damage.

- Run pump-saver antifreeze through the pump according to the product instructions.

- Store the pump in a frost-free environment.

6. Maintenance

Regular maintenance ensures optimal performance and extends the life of your pump.

6.1 Pump Oil

- Initial Oil Change: Change the pump oil after the first 50 hours of operation.

- Subsequent Oil Changes: Change the pump oil every 3 months or 200 hours of operation, whichever comes first.

- Use only non-detergent pump oil specifically designed for pressure washer pumps (e.g., General Pump Series 100 oil).

- Check the oil level before each use.

6.2 Inlet Filter

- Inspect and clean the inlet filter before each use.

- Replace the filter if it is damaged or cannot be cleaned effectively.

6.3 Seals and Valves

- Periodically inspect pump seals for leaks. Replace worn seals promptly to prevent internal damage.

- Check the unloader valve and thermal relief valve for proper function. Do not attempt to repair these components if you are not trained. Consult a qualified service technician.

6.4 General Cleaning

- Keep the exterior of the pump clean and free of dirt and debris.

- Ensure cooling fins (if present) are clear for proper heat dissipation.

7. Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| No pressure or low pressure |

|

|

| Pump making unusual noise (e.g., knocking, grinding) |

|

|

| Water leaking from pump |

|

|

| Thermal relief valve frequently activating |

|

|

8. Specifications

| Model | EZ4040G Series 44 (EZ4040) |

| Brand | General Pump |

| Maximum Pressure | 4000 PSI |

| Maximum Flow Rate | 4 Gallons Per Minute (GPM) |

| Material | Brass (Pump Head) |

| Power Source | Gasoline-powered (requires external engine) |

| Product Dimensions | 12.7"L x 9.2"W x 10.6"H |

| Item Weight | 22.4 pounds (10.17 Kilograms) |

| Included Components | Bypass Hose, Inlet Filter, Thermal Relief Valve, Unloader Valve |

9. Warranty Information

General Pump products are manufactured to high standards. Specific warranty terms and conditions may vary. Please refer to the warranty card included with your purchase or visit the official General Pump website for detailed warranty information. Keep your proof of purchase for any warranty claims.

10. Customer Support

For technical assistance, replacement parts, or service inquiries, please contact General Pump customer support or an authorized service center. Contact information can typically be found on the manufacturer's website or on the product packaging.

You may also visit the General Pump Store on Amazon for additional product information and resources.