1. Introduction

The SEAFLO Ultrasonic Hull Defense System (Model SFUAS1-01) is an advanced, automated anti-fouling device designed to protect your vessel's hull, drives, and running gear from marine growth such as barnacles, algae, and microorganisms. This system utilizes high-frequency ultrasonic pulses to create an environment that prevents fouling organisms from attaching, thereby reducing drag, improving fuel efficiency, and extending the lifespan of your bottom paint.

This manual provides essential information for the safe and effective installation, operation, and maintenance of your SEAFLO Ultrasonic Hull Defense System.

Image 1.1: Overview of the SEAFLO Ultrasonic Hull Defense System and its benefits, including a visual comparison of a fouled hull (before) and a clean hull (after).

2. Safety Information

- Always disconnect power before performing any installation or maintenance.

- Ensure all electrical connections are secure and waterproof to prevent short circuits or damage.

- Do not attempt to open or repair the control unit or transducer. Refer to qualified personnel for service.

- Keep the control unit in a dry, well-ventilated area, away from direct sunlight and excessive heat.

- The transducer is designed for continuous underwater operation (IP68 rated). Ensure proper sealing during installation.

3. Product Components

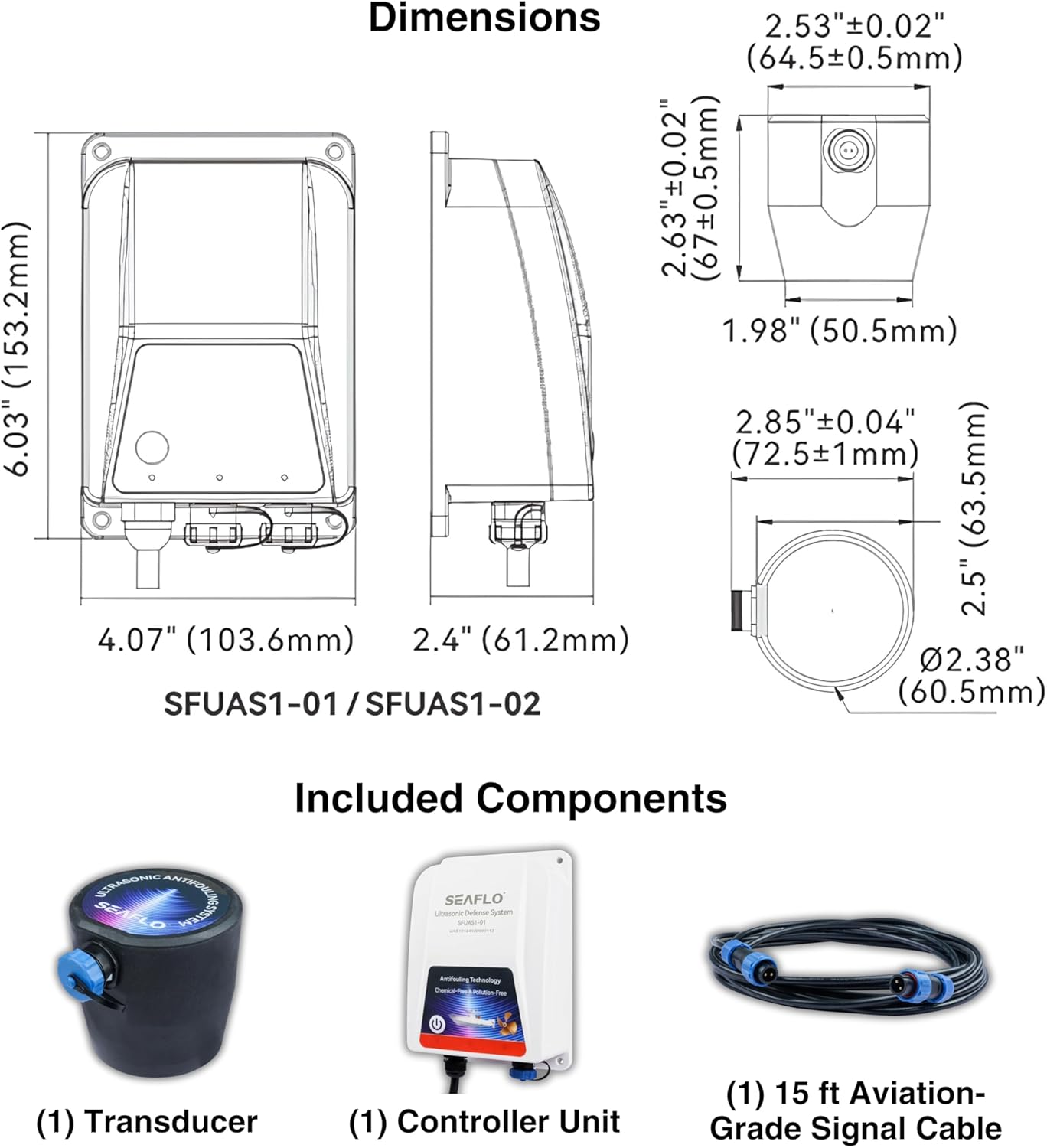

The SEAFLO Ultrasonic Hull Defense System (SFUAS1-01) includes the following components:

- (1) Ultrasonic Transducer

- (1) Control Unit

- (1) 15 ft Aviation-Grade Signal Cable

Image 3.1: Visual representation of the system's included components and their dimensions.

4. Specifications

| Feature | Specification |

|---|---|

| Model | SFUAS1-01 |

| Voltage | 12V DC |

| Coverage per Transducer | Approximately 200 sq.ft |

| Frequency Range | 20–45 kHz (adjustable) |

| Waterproof Rating | IP68 Submersible (Transducer) |

| Signal Cable Length | 15 ft (Aviation-Grade) |

| Control Unit Dimensions | 153.2mm (H) x 103.6mm (W) x 61.2mm (D) |

| Transducer Dimensions | 67mm (H) x 60.5mm (Diameter) |

| Item Weight | 4.18 kg |

Image 4.1: The system operates with an adjustable frequency range from 20 kHz to 45 kHz.

5. Setup and Installation

The SEAFLO Ultrasonic Hull Defense System is designed for straightforward DIY installation. No special tools or technical expertise are required.

5.1 Transducer Placement and Coverage

Each transducer provides approximately 200 square feet of protected underwater surface area. For optimal performance, consider the following:

- Hull Coverage: A rough estimate of your underwater surface area can be calculated by doubling your draft, adding it to your beam, then multiplying by your LWL (length at water line).

- Isolated Components: Isolated underwater parts such as drive shafts, propellers, rudders, exterior engine brackets, struts, swim platforms, and trim tabs require their own dedicated transducer for effective protection, as ultrasonic signals from the hull may not reach them effectively.

Image 5.1: Guide for determining the number of transducers needed for monohull and catamaran vessels based on length.

Image 5.2: Examples of transducer placement for various drive types, including pods, sterndrives, and inboard/sail drives.

5.2 Installation Steps

- Mount the Control Unit: Select a dry, protected location inside your vessel for the control unit. Ensure it is easily accessible for wiring and inspection.

- Mount the Transducer: The transducer should be mounted directly to the inside of the hull or the component requiring protection. Ensure good contact with the surface. For isolated components, mount the transducer directly to that component. The transducer is IP68 submersible.

- Connect Signal Cable: Connect the 15 ft aviation-grade signal cable between the transducer and the control unit. The connectors are waterproof and designed for secure, hassle-free connectivity.

- Connect Power: Connect the control unit to a 12V DC power source. Ensure proper polarity.

- Initial Power-Up: Once all connections are secure, apply power. The system will perform automatic calibration upon startup.

Image 5.3: Features highlighting the fully automated operation, standalone IP68 sensor, easy installation with a 15 ft signal cable, and high protection aviation connectors.

6. Operating Instructions

The SEAFLO Ultrasonic Hull Defense System is fully automated and designed for continuous 24/7 operation. Once installed and powered, the system automatically adjusts its ultrasonic pulse intervals based on battery power to ensure efficient operation.

6.1 Operating Modes

The system operates in multiple modes, adapting to power availability:

- Full Power: Output Range: 12.7V to 18.0V. Provides maximum anti-fouling protection.

- Reduced Power: Output Range: 12.0V to 12.6V. Maintains effective protection with lower power consumption.

- Sleep/Idle: Output Range: Below 12.0V. Enters a low-power state to conserve battery while still offering some level of protection.

Image 6.1: The system's multiple operating modes based on input voltage.

The system's advanced ultrasonic technology continuously repels marine organisms, preventing them from attaching to your vessel's surfaces. This process is chemical-free and pollution-free.

Image 6.2: Explanation of how high-frequency ultrasonic pulses prevent marine organisms from attaching to the hull.

7. Maintenance

The SEAFLO Ultrasonic Hull Defense System is designed to be largely maintenance-free. Its continuous operation and automated calibration minimize the need for user intervention.

- Periodic Inspection: Periodically inspect the control unit and transducer cables for any signs of damage or wear. Ensure all connections remain secure.

- Transducer Surface: While the system actively prevents fouling, a quick visual check of the transducer's mounting area during haul-outs can confirm optimal performance.

- Cleaning: If the control unit becomes dusty, gently wipe it with a dry cloth. Do not use harsh chemicals or abrasive cleaners.

By keeping hull surfaces cleaner for longer, the system significantly reduces the frequency and intensity of abrasive hull cleaning, thereby extending bottom paint lifespan and protecting hull coatings.

8. Troubleshooting

If you encounter issues with your SEAFLO Ultrasonic Hull Defense System, consider the following troubleshooting steps:

- No Power to Control Unit:

- Check the 12V DC power connection to ensure it is secure and receiving power.

- Verify that the vessel's battery is adequately charged.

- System Not Operating (No Ultrasonic Activity):

- Ensure the signal cable between the control unit and transducer is firmly connected at both ends.

- Confirm the control unit is receiving sufficient voltage (refer to Operating Modes in Section 6.1).

- Reduced Anti-Fouling Effectiveness:

- Verify that the transducer is securely mounted and has good contact with the hull or component.

- Ensure the number of transducers installed is appropriate for your vessel's size and configuration (refer to Section 5.1).

- Check for any obstructions near the transducer that might interfere with ultrasonic wave propagation.

If problems persist after following these steps, please contact SEAFLO customer support.

9. Warranty and Support

9.1 Warranty Information

The SEAFLO Ultrasonic Hull Defense System (SFUAS1-01) is backed by SEAFLO's industry-leading 4-Year Limited Warranty. This warranty guarantees superior product quality and dependable performance. Please retain your proof of purchase for warranty claims.

9.2 Customer Support

For technical assistance, warranty inquiries, or further information, please visit the official SEAFLO website or contact their customer support department. Contact details can typically be found on the product packaging or the manufacturer's website.