1. Introduction

This manual provides detailed instructions for the safe and efficient operation, setup, and maintenance of your Gpxhbcb Automatic Birthday Cake Smoothing Coating Machine. This machine is designed to simplify the process of applying cream coatings to cakes, ensuring a smooth and professional finish for cakes ranging from 4 to 12 inches in diameter and up to 20 cm (7.87 inches) in height.

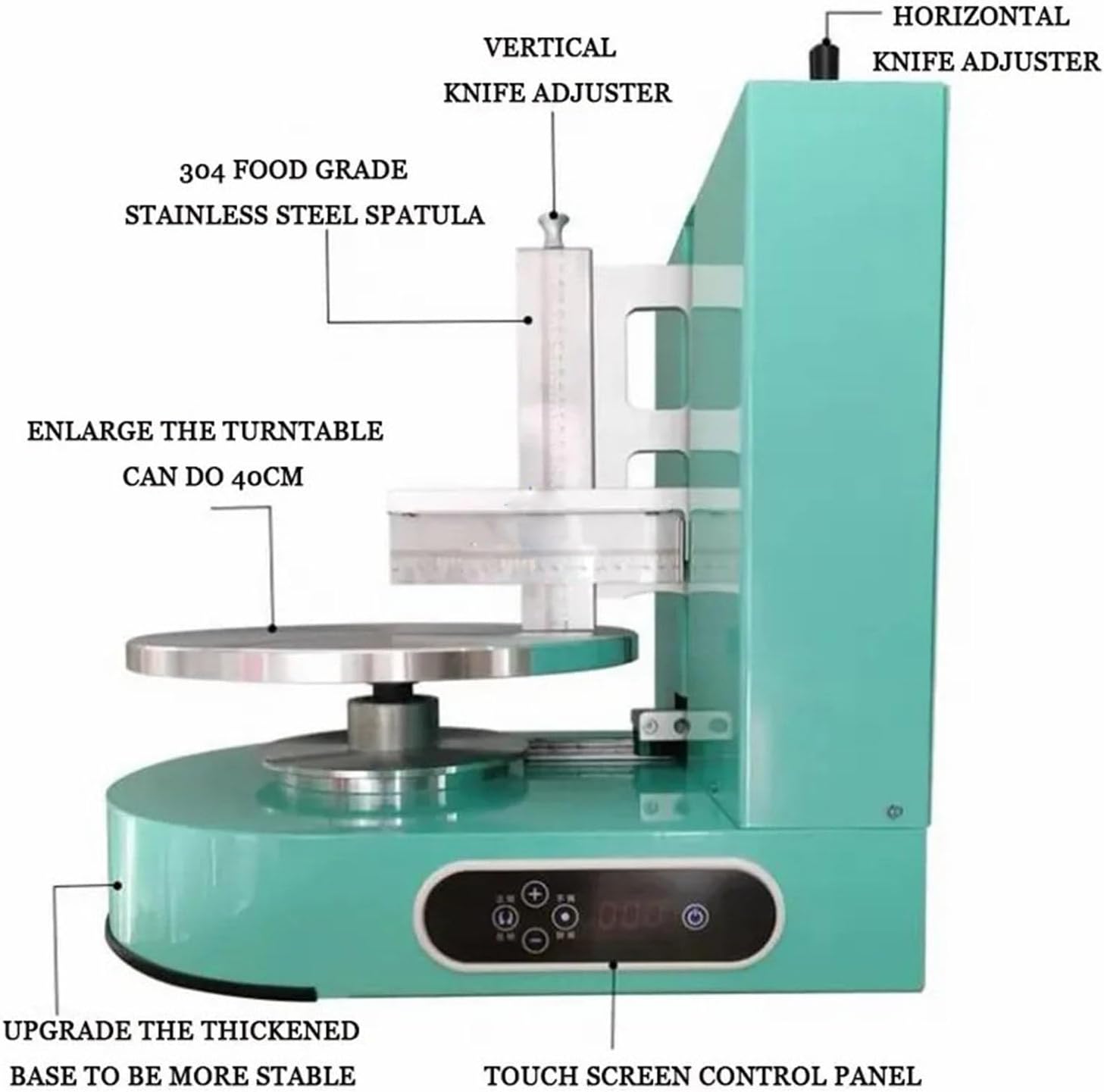

Figure 1: The Automatic Cake Smoothing Coating Machine, illustrating its use in creating professionally finished cakes.

2. Product Features

- Versatile Cake Sizing: Capable of smoothing and coating cakes from 4 to 12 inches in diameter and up to 21.5 cm (8.46 inches) in height, accommodating various baking needs.

- Durable Construction: Manufactured from high-quality 304 stainless steel for the spatula and aluminum alloy for the turntable, ensuring corrosion resistance, rust-free performance, and ease of cleaning. The machine features an electrostatic spray of high-temperature powder on its surface for enhanced durability.

- Adjustable Scraper Mechanism: Equipped with a cutting head lifter for easy rotation and height adjustment, allowing precise control over cake height and cream thickness.

- User-Friendly Interface: Features a waterproof LCD module with touch control for one-key access, forward and reverse rotation, and simple operation.

- Enhanced Stability: Designed with an upgraded, thickened base for increased stability during operation.

Figure 2: The machine accommodates various cake diameters, from 4 to 12 inches.

Figure 3: Key components of the cake smoothing machine, including adjustable knives and control panel.

Figure 4: Details of the machine's high-quality materials and precise control features.

Figure 5: The automatic smoother significantly reduces the time required for cake coating compared to manual methods.

3. Setup

- Unpacking: Carefully remove all components from the packaging. Inspect for any damage during transit.

- Placement: Place the cake spreader on a stable, level, and clean surface. Ensure adequate space around the machine for safe operation.

- Power Connection: Connect the machine to a suitable power outlet (AC110V/60Hz or AC220V/50Hz, depending on your model).

- Initial Cleaning: Before first use, wipe down all food-contact surfaces, especially the turntable and spatula, with a damp cloth and mild detergent. Rinse thoroughly and dry.

- Install Turntable and Scrapers: Ensure the aluminum alloy turntable is securely placed. Position the vertical and horizontal scrapers as shown in Figure 3.

4. Operating Instructions

Follow these steps for effective cake smoothing and coating:

- Prepare the Cake Blank: First, place the cake blank (unfrosted cake) precisely in the center of the turntable. Ensure it is stable.

- Adjust Scraper Distance: Adjust the distance between the horizontal knife and the vertical knife to 5-8mm. This gap allows for the cream thickness.

- Power On and Set Speed: Turn on the power using the control panel. Adjust the rotation speed of the turntable to approximately 60-80 revolutions per minute (rpm).

- Apply Cream: Spread the butter cream evenly onto the cake. Begin by applying cream from the bottom to the top, and from the inside outwards, ensuring good coverage.

- Adjust Horizontal Knife Pressure: Adjust the pressing force of the horizontal knife. Observe the cake; adjust until a smooth, even edge (water chestnut appearance) begins to form.

- Final Smoothing: Allow the machine to complete the smoothing process. The vertical and horizontal knives will create a uniform coating.

- Remove Scrapers and Cake: Once the desired smoothness is achieved, carefully remove the horizontal knife and then the vertical knife. Gently take out the finished cake from the turntable.

Figure 6: Visual guide to the cake smoothing process.

5. Maintenance

Regular cleaning and maintenance will ensure the longevity and optimal performance of your machine.

- Daily Cleaning: After each use, disconnect the power. Remove the turntable and scrapers. Wash these components with warm, soapy water and a soft sponge. Rinse thoroughly and dry completely before reassembly or storage.

- Machine Body: Wipe the main body of the machine with a damp cloth. Avoid direct water exposure to electrical components. Do not use abrasive cleaners or scouring pads, as these can damage the surface finish.

- Storage: Store the machine in a clean, dry place away from direct sunlight and extreme temperatures.

- Inspection: Periodically inspect all moving parts and connections for wear or damage. If any issues are found, contact customer support.

6. Troubleshooting

If you encounter any issues with your cake smoothing machine, refer to the following common problems and solutions:

- Machine Does Not Turn On:

- Ensure the power cord is securely plugged into both the machine and a working electrical outlet.

- Check the power switch on the machine.

- Verify that the power outlet is functional by testing it with another appliance.

- Cake Coating is Uneven:

- Ensure the cake blank is perfectly centered on the turntable.

- Adjust the distance between the horizontal and vertical knives carefully (5-8mm).

- Verify that the cream consistency is appropriate for spreading.

- Check the turntable speed; adjust to 60-80 rpm for optimal results.

- Scrapers Not Moving Smoothly:

- Ensure the scraper components are clean and free of dried cream or debris.

- Check for any obstructions in the scraper's path.

For issues not listed here or if problems persist, please contact customer support.

7. Specifications

| Specification | Detail |

|---|---|

| Product Name | Cake Cream Spreading Machine |

| Power | 200W |

| Voltage | AC110V/60Hz or AC220V/50Hz |

| Product Size | 50 x 37 x 48 cm (19.68 x 14.57 x 18.9 inches) |

| Net Weight | 23 kg (50.6 pounds) |

| Cake Diameter Compatibility | 4-12 inches |

| Cake Height Compatibility | 0-20 cm (0-7.87 inches) |

| Turntable Material | Aluminum Alloy |

| Spatula Material | 304 Stainless Steel |

| ASIN | B0DQCTR5D9 |

| Date First Available | December 13, 2024 |

Figure 7: Dimensional overview of the cake smoothing machine.

8. Warranty and Support

Your purchase includes a 30-day easy return policy. For any product-related inquiries, technical assistance, or warranty claims, please refer to your purchase documentation or contact the seller directly through the platform where the product was purchased.