1. Introduction

This manual provides essential information for the safe and efficient installation, operation, and maintenance of your RunTru 60K BTU 80% AFUE 4 Ton Natural Gas Furnace, Model A801X. Please read this manual thoroughly before attempting any procedures. Retain this manual for future reference.

This furnace is designed to provide reliable heating for residential applications, featuring an 80% AFUE efficiency rating and a multi-speed blower for consistent comfort.

2. Safety Information

WARNING: Improper installation, adjustment, alteration, service, or maintenance can cause property damage, personal injury, or loss of life. Consult a qualified installer, service agency, or the gas supplier before making any adjustments or modifications.

- Always turn off electrical power and gas supply to the unit before performing any service or maintenance.

- Ensure proper ventilation and combustion air supply as per local codes and manufacturer instructions.

- Do not store flammable materials, gasoline, or other combustible vapors and liquids near the furnace.

- Never operate the furnace without the access panels securely in place.

- Carbon Monoxide (CO) is a colorless, odorless, and poisonous gas. Install and maintain CO detectors in your home.

- This appliance must be installed by a qualified professional.

3. Product Overview

The RunTru A801X Series furnace is a high-efficiency heating system designed for versatile installation and reliable performance.

Figure 3.1: Front view of the RunTru 60K BTU Natural Gas Furnace, Model A801X.

Key Features:

- Heating System: Equipped with a versatile natural or propane gas option and a single-stage, multi-speed blower design for consistent, comfortable heating.

- Efficiency: Converts 80% of its fuel into home heating, with 20% used in normal operation and vented out. Designed with durable metal flue venting.

- Installation Flexibility: Offers multi-positional configurations (Upflow, Downflow, Horizontal) to suit various installation requirements.

4. Specifications

Detailed technical specifications for the RunTru A801X Series furnace.

Figure 4.1: Dimensions of the RunTru A801X Series Furnace. The unit measures 34.00 inches in height, 17.50 inches in width, and 28.75 inches in depth.

Figure 4.2: Detailed specifications including AHRI number, heating capacity, stage type, and electrical requirements.

| Attribute | Value |

|---|---|

| Brand | RunTru |

| Model | A801X |

| Product Dimensions (D x W x H) | 28.75" x 17.5" x 34" |

| Mounting Type | Floor Mount |

| UPC | 721750058232 |

| AHRI Number | 204606302 |

| Heating Capacity | 60,000 BTU/h |

| Stage Type | Single Stage |

| Maximum CFM | 1075 (4 Ton) |

| Venting Type | Metal Flue |

| Blower Type | Multi-Speed |

| Ignitor Type | 120 V SiNi |

| Ship Weight | 102 lbs (46.27 kg) |

| Electrical | 120 V 1-Phase 60 Hz |

| Orientation | Multi-Positional |

| Propane LP Kit | BAYLPSS400C (Unit is ready for Natural Gas) |

| Heat Exchanger | 20 Gauge (Fired) Aluminized Steel |

| Efficiency Rating (AFUE) | 80.0% |

Figure 4.3: Energy Guide and AHRI Certificate of Product Ratings for the RunTru A801X Series Furnace, showing an 80.0% AFUE rating.

The efficiency of this furnace can vary depending on the type of air handler or blower installed by your contractor. High-quality components enhance heating performance and overall energy efficiency.

5. Installation and Setup

IMPORTANT: Installation must be performed by a qualified HVAC technician in accordance with all local and national codes and manufacturer instructions.

5.1 Multi-Positional Installation

The RunTru A801X furnace is designed for flexible installation in Upflow, Downflow, or Horizontal configurations.

Figure 5.1: Diagram illustrating Upflow and Downflow vertical furnace orientations.

- Upflow: The heat exchanger is positioned on top of the unit. Cool air is pulled from the side or bottom, heated, and released from the top. Commonly used in basements.

- Downflow: The heating coil or heat exchanger is located beneath the main furnace unit. Air enters from the top and exits from the bottom. Commonly used in closets or utility rooms.

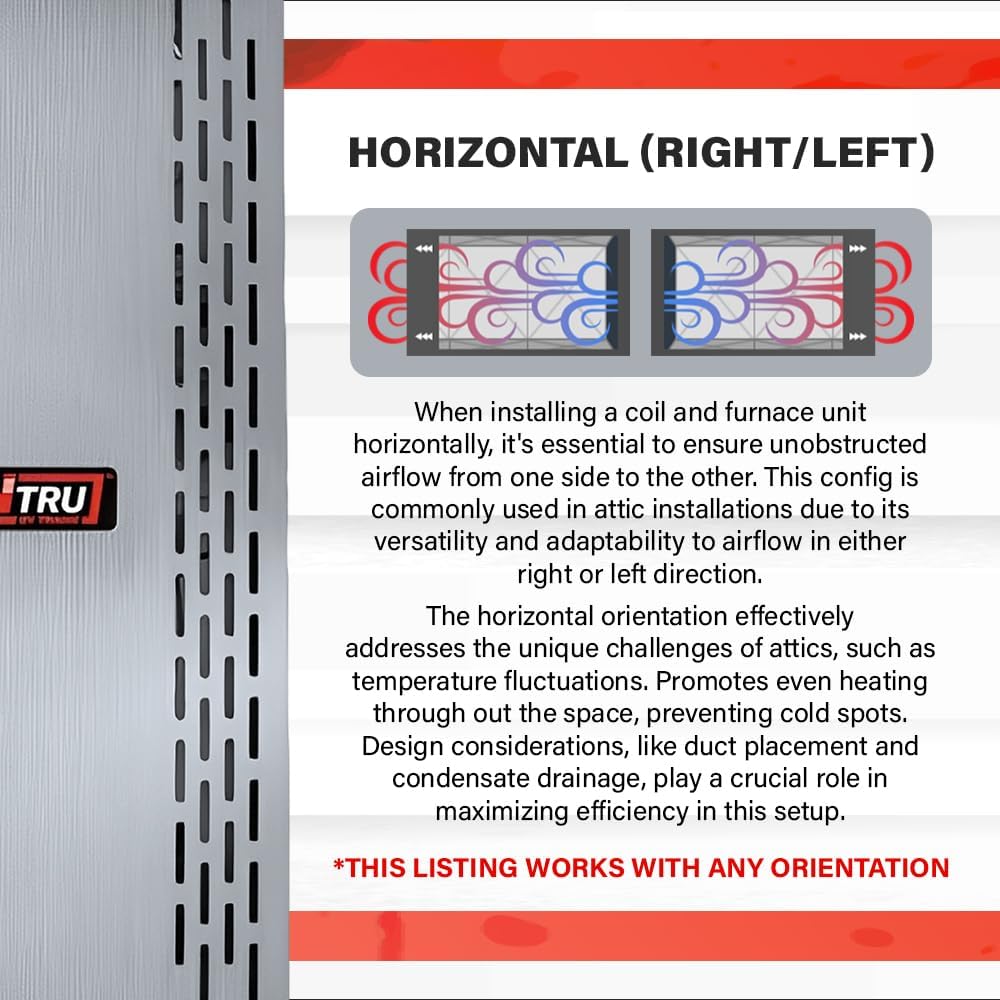

Figure 5.2: Diagram illustrating Horizontal (Right/Left) furnace orientation.

Horizontal: When installing horizontally, ensure unobstructed airflow. This configuration is common in attic installations and allows for adaptability to airflow in either right or left directions. Proper duct placement and condensate drainage are crucial for efficiency.

5.2 Gas Supply Connection

The furnace is factory-configured for natural gas. If converting to propane (LP) gas, an LP conversion kit is required.

Figure 5.3: Components of an LP Conversion Kit. This kit allows the furnace to operate on propane gas.

NOTE: This furnace does NOT comply with California Low NOx or Ultra-Low NOx regulations.

5.3 Electrical Connection

Connect the furnace to a dedicated 120 V, 1-Phase, 60 Hz electrical supply as per local electrical codes. Ensure proper grounding.

5.4 Ductwork Connection

Connect the supply and return air ducts to the furnace. Ensure all connections are sealed to prevent air leaks and optimize system efficiency.

6. Operating Instructions

Once installed by a qualified technician, operating your RunTru furnace is straightforward.

6.1 Initial Startup

- Ensure all access panels are securely in place.

- Open the gas supply valve to the furnace.

- Turn on the electrical power to the furnace.

- Set your thermostat to the "Heat" mode and adjust the temperature setting above the current room temperature.

- The furnace will initiate its startup sequence, which typically includes a pre-purge cycle, ignitor activation, and main burner ignition.

- Observe the furnace for proper operation during the first heating cycle. If any unusual noises or odors are detected, turn off the furnace and contact a qualified technician.

6.2 Normal Operation

The furnace will cycle on and off as needed to maintain the temperature set on your thermostat. The multi-speed blower will distribute heated air throughout your home.

For optimal performance, keep your thermostat set to a comfortable temperature and avoid frequent, drastic temperature changes.

7. Maintenance

Regular maintenance ensures the longevity and efficient operation of your furnace. Always turn off power and gas before performing maintenance.

7.1 Air Filter Replacement

Inspect and replace the air filter monthly, or more frequently if you have pets or allergies. A dirty filter restricts airflow, reduces efficiency, and can damage the furnace.

- Locate the filter slot, typically near the return air duct.

- Remove the old filter and note its size and airflow direction.

- Insert a new, clean filter, ensuring the airflow arrow points towards the furnace.

7.2 Annual Professional Inspection

It is highly recommended to have a qualified HVAC technician inspect and service your furnace annually, preferably before the heating season begins. This includes:

- Checking and cleaning the burners.

- Inspecting the heat exchanger for cracks or damage.

- Verifying proper gas pressure and combustion.

- Lubricating moving parts (if applicable).

- Testing safety controls and electrical connections.

- Cleaning the blower assembly.

8. Troubleshooting

Before calling for service, review the following common issues and solutions. Always turn off power and gas before inspecting the unit.

| Problem | Possible Cause | Solution |

|---|---|---|

| No Heat | Thermostat set incorrectly | Set thermostat to "Heat" and desired temperature. |

| Power switch off | Ensure furnace power switch is on. Check circuit breaker. | |

| Gas supply off | Ensure gas valve to furnace is open. | |

| Dirty air filter | Replace or clean air filter. | |

| Weak Airflow | Dirty air filter | Replace or clean air filter. |

| Blocked return/supply vents | Ensure all vents are open and unobstructed. | |

| Unusual Noises | Loose panel or component | Inspect for loose parts. Tighten if safe to do so. |

| Blower motor issue | Contact a qualified technician. |

If the problem persists after attempting these solutions, or if you encounter any other issues, contact a qualified HVAC service technician.

9. Warranty Information

The RunTru A801X Series furnace comes with the following warranty conditions:

- Heat Exchanger: 20 years

- Parts: 10 years

These warranty durations are applicable when the unit is installed by a qualified technician and registered online with the manufacturer at no additional charge. Please refer to the official RunTru warranty documentation for complete terms and conditions.

10. Customer Support

For technical assistance, service inquiries, or to locate a qualified RunTru service provider, please refer to the contact information provided with your product packaging or visit the official RunTru website.

When contacting support, please have your model number (A801X) and serial number ready.