Hanchen HT-1115B-MYF RO Booster Pump Kit Instruction Manual

Model: HT-1115B-MYF | Brand: Hanchen

1. Introduction

This manual provides detailed instructions for the installation, operation, and maintenance of your Hanchen HT-1115B-MYF RO Booster Pump Complete Kit. This kit is designed to enhance the performance of home Reverse Osmosis (RO) water purification systems by increasing water pressure, improving filtration efficiency, and reducing wastewater generation. It features a quick-connection design and includes high and low pressure switches for automatic operation and dry-running protection.

2. Package Contents

Verify that all components listed below are present in your package:

- HCRO-400G Booster Pump

- High Pressure Switch

- Low Pressure Switch

- Quick Connection Couplers (various types: I-type, T-type, L-type)

- 1/4" Water Pipe

- DC 24V Power Adapter

- Connection Wires (pre-wired, two sets)

Image: Detailed view of all components included in the Hanchen RO Booster Pump Kit, showing the pump, power adapter, various quick connectors, water pipe, and connection wires.

3. Specifications

| Feature | Specification |

|---|---|

| Model Number | HT-1115B-MYF |

| Manufacturer | Hanchen |

| Item Weight | 5.33 pounds |

| Product Dimensions | 7 x 3 x 3 inches |

| Color | Black |

| Material | Plastic |

| Power Source | Corded Electric |

| Suitable RO System Flow Rate | Up to 100 GPD |

| Pressure Boost | From 40 psi to 70-80 psi |

| High Pressure Switch Function | Automatic start and stop of the booster pump |

| Low Pressure Switch Function | Prevents booster pump dry running |

4. Setup and Installation

Follow these steps for proper installation of the Hanchen RO Booster Pump Kit:

- Identify Components: Familiarize yourself with the booster pump, power adapter, high pressure switch, low pressure switch, and various quick connectors.

- Placement: Choose a suitable location for the booster pump near your RO system, ensuring it is protected from moisture and direct sunlight.

- Connect Low Pressure Switch: Install the low pressure switch on the inlet side of the booster pump, before the pump. This switch prevents the pump from running dry if the incoming water supply is insufficient.

- Connect High Pressure Switch: Install the high pressure switch on the outlet side of the RO membrane, typically before the storage tank. This switch will turn off the pump when the RO system reaches its desired pressure (e.g., the storage tank is full).

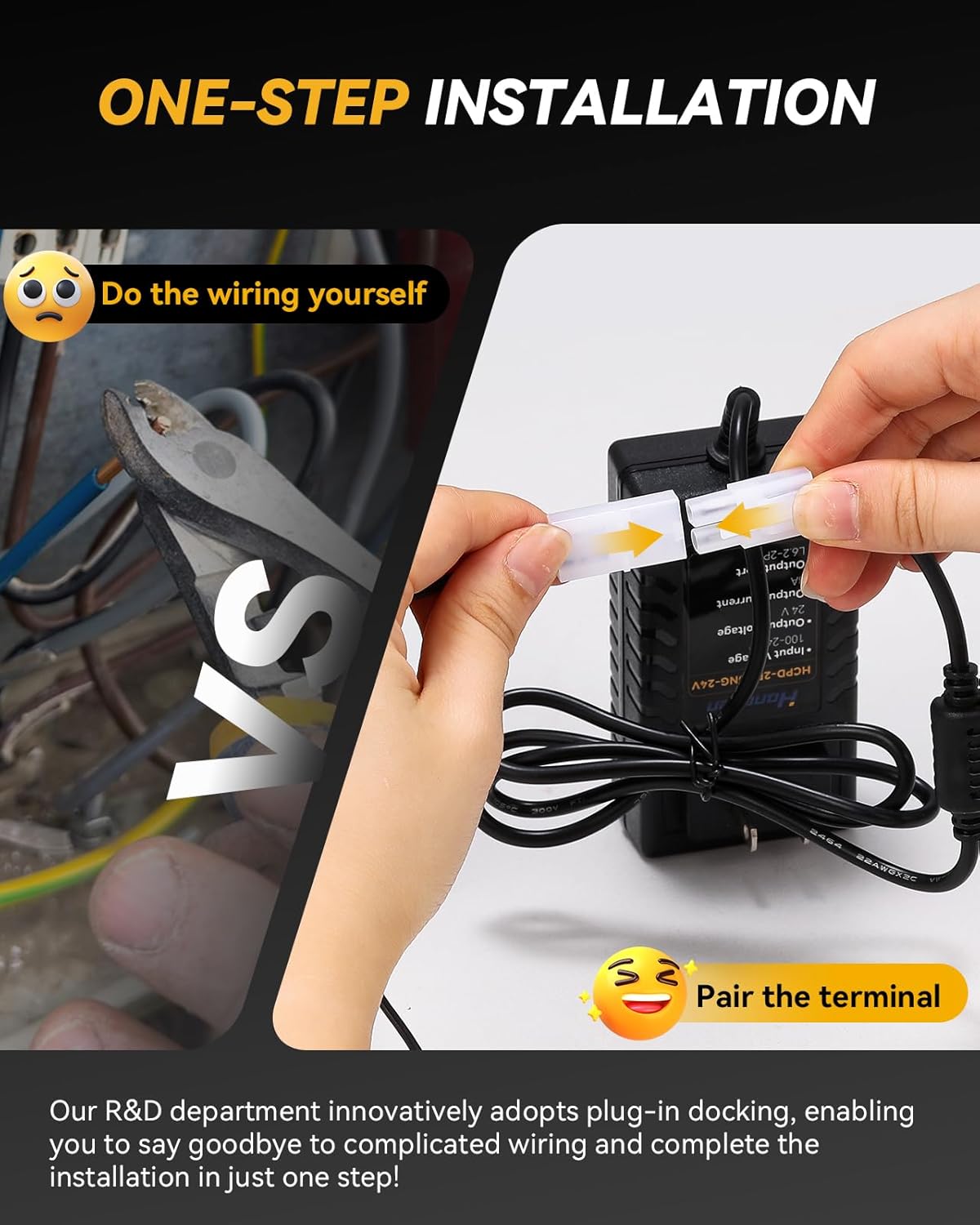

- Water Connections: Use the provided 1/4" water pipe and quick connectors to integrate the pump and switches into your existing RO system. Ensure all connections are secure and leak-free. The quick-connect design allows for one-step installation without complex wiring for the water lines.

- Electrical Connections: The kit features a plug-and-play design. Connect the pre-wired connection wires from the pump and switches to the DC 24V power adapter. Ensure correct polarity if not pre-assembled.

- Power On: Once all connections are secure, plug the power adapter into a suitable electrical outlet. The pump should activate when the RO system requires water pressure.

Image: Diagram illustrating the typical installation of the booster pump, high pressure switch, and low pressure switch within a reverse osmosis water purification system, showing water flow and electrical connections.

Image: Illustration demonstrating the simplicity of the quick-connect design for electrical connections, contrasting it with traditional wiring methods.