1. Introduction

This manual provides essential information for the safe and efficient operation, installation, and maintenance of the Wilo-STAR-RS25/6 Hot Water Circulation Pump. Please read these instructions carefully before installation and use to ensure proper function and to prevent damage or injury.

Figure 1: Cover of the Wilo-Star RS, RSD Installation and Operating Instructions Manual. This image shows the front cover of the official manual, indicating it covers installation and operating instructions in multiple languages.

2. Safety Instructions

Adhering to these safety guidelines is crucial for safe operation and longevity of your pump.

Figure 2: Wilo-Star RS Do's and Don'ts. This graphic outlines critical actions to take and avoid for the proper functioning and safety of the pump.

Do's:

- Read the Manual: Always start by reading the manufacturer's manual for specific instructions and recommendations.

- Proper Installation: Ensure the pump is installed correctly, with all connections secure and no leaks.

- Initial Priming: Prime the pump initially to avoid dry running and ensure proper operation.

- Proper Electrical Connection: Ensure proper electrical connection with appropriate protection.

- Earthing Connection: Always ensure the pump has a proper earthing connection.

Don'ts:

- Avoid Piping Leakages: Do not operate the pump with any piping leaks.

- Never Run Pump by Closing Suction Valve: Do not run the pump if the suction valve is closed.

- Do Not Use Under-sizing and Over-sizing Pipes: Use pipes of the correct size as specified.

- Avoid Dry Running: Never allow the pump to run dry.

3. Product Features

The Wilo-STAR-RS25/6 Hot Water Circulation Pump offers several key features designed for reliable performance:

- Application: Ideal for hot water circulation in bungalows, farmhouses, apartments, hotels, hostels, and similar establishments.

- Installation Flexibility: Suitable for any installation location with a horizontal shaft; the terminal box can be positioned in 3-6-9-12 o'clock positions.

- Speed Control: Features three preselectable speed stages for precise load adjustment.

- Easy Installation: Designed for easy and safe installation due to a practical wrench attachment point on the pump body.

- Simplified Electrical Connection: Electrical installation is simplified with a terminal box featuring a removable threaded cable connection that can be used on both sides, and quick connection with spring clips.

Figure 3: Wilo-STAR-RS25/6 Hot Water Circulation Pump. This image displays the main unit of the pump, highlighting its compact design and connection points.

4. Technical Specifications

Detailed specifications for the Wilo-STAR-RS25/6 Hot Water Circulation Pump:

| Parameter | Value |

|---|---|

| Flow | Up to 64 LPM (Liters Per Minute) |

| Head | Up to 5.5 m (meters) |

| Power | 40 Watt |

| Voltage | 1 Phase ~ 230 V, 50 Hz |

| Pipe Size | 40 mm / 40 mm |

| Manufacturer | WILO Pumps India |

| Item Model Number | W_4032956 |

| Product Dimensions (LxWxH) | 15 x 10 x 20 cm |

| Item Weight | 2.6 kg |

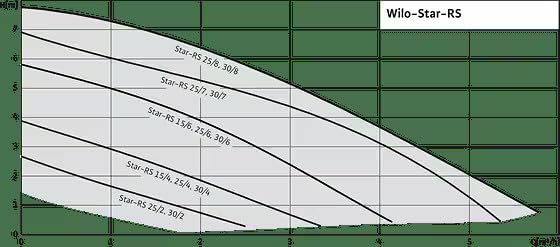

Figure 4: Wilo-Star-RS Pump Performance Curve. This graph illustrates the relationship between pump head (m) and flow rate (m³/h) for various Wilo-Star-RS models, including the 25/6, under different operating conditions.

5. Installation

Proper installation is critical for the safe and efficient operation of your Wilo-STAR-RS25/6 pump. Refer to the "Do's" section for key safety points.

- Mounting Location: Select an installation location with a horizontal shaft. The terminal box can be rotated to 3, 6, 9, or 12 o'clock positions for convenience.

- Pipe Connections: Ensure all pipe connections are secure and free from leaks. Use appropriate pipe sizes (40 mm / 40 mm) to avoid under-sizing or over-sizing, which can affect performance. The pump body includes a practical wrench attachment point for easier installation.

- Electrical Connection: Connect the pump to a 1 Phase ~ 230 V, 50 Hz power supply. Ensure proper electrical protection is in place. The terminal box features a removable threaded cable connection that can be used on both sides, and quick connection with spring clips simplifies wiring. Always ensure a proper earthing connection.

- Priming: Before initial operation, prime the pump to prevent dry running. Follow the specific priming instructions in the full manufacturer's manual.

6. Operation

Once installed and primed, the Wilo-STAR-RS25/6 pump is ready for operation.

- Power On: Switch on the power supply to the pump.

- Speed Selection: The pump features three preselectable speed stages. Adjust the speed according to the required load and system demands. Refer to the performance curve (Figure 4) for guidance on flow and head at different settings.

- Monitoring: Regularly monitor the pump for unusual noises, vibrations, or leaks during operation.

- Avoid Dry Running: Ensure the pump always has water flowing through it. Dry running can cause severe damage.

7. Maintenance

Regular maintenance ensures the longevity and optimal performance of your circulation pump.

- Regular Inspections: Periodically check for any signs of wear, corrosion, or leaks in the pump and piping system.

- Cleaning: Keep the pump exterior clean and free from dust and debris to ensure proper heat dissipation.

- Electrical Connections: Ensure all electrical connections remain tight and free from corrosion.

- System Flushing: If the system water quality is poor, consider periodic flushing to prevent sediment buildup within the pump.

- Professional Service: For any complex maintenance or repairs, contact a qualified service technician.

8. Troubleshooting

This section provides basic troubleshooting steps for common issues. For more complex problems, consult a qualified technician.

| Problem | Possible Cause | Solution |

|---|---|---|

| Pump does not start | No power supply; tripped circuit breaker; motor blockage | Check power connection and circuit breaker; inspect for blockages and clear if safe to do so. |

| Low flow or no water circulation | Air in the system (not primed); closed valves; blockages in pipes or pump; incorrect speed setting | Ensure pump is properly primed; check all valves are open; inspect for blockages; adjust speed setting. |

| Unusual noise or vibration | Air in the system; cavitation; loose mounting; foreign objects in pump | Bleed air from the system; check for proper water supply; ensure pump is securely mounted; inspect for foreign objects (power off first). |

| Leakage | Loose pipe connections; damaged seals | Tighten pipe connections; if seals are damaged, contact service for replacement. |

9. Warranty and Support

For warranty information, technical support, or service inquiries, please contact Wilo Pumps India directly. Keep your purchase receipt and product model number (W_4032956) handy when contacting support.

Manufacturer: WILO Pumps India

For further assistance, please visit the official Wilo website or refer to the contact information provided with your product packaging.