1. Product Overview

The MUNEFE Manual Lubricating Oil Pump is a robust and efficient device designed for precise lubrication in various industrial applications. Constructed from high-quality metal, it ensures durability and resistance to wear. This pump is ideal for use with punching machines, lathes, cutting machines, and milling machines, providing efficient oil distribution to enhance machine longevity and performance.

Its manual operation allows for precise control over lubrication, and it can be integrated with a throttling distributor for a comprehensive lubrication setup. The pump supports oils with viscosities ranging from N20 to N1000 and features high-quality seals to minimize leakage.

Key Features:

- Robust Construction: Made from high-quality metal for durability and wear resistance.

- Versatile Applications: Suitable for punching machines, lathes, cutting machines, and milling machines.

- Efficient Manual Operation: Hand-operated plunger mechanism for precise oil expulsion and retraction.

- Customizable Lubrication: Integrates with throttling distributors and supports a wide range of oil viscosities (N20-N1000).

- Leak-Resistant Design: Equipped with high-quality seals to prevent leaks and ensure clean operation.

- Dual Outlet Ports: Features two discharge ports (left and right) for flexible setup.

2. Specifications

| Attribute | Value |

|---|---|

| Pump Material | Metal |

| Pump Shaft Position | Vertical Side |

| Impeller Suction Method | Single Suction |

| Drive Mode | Manual |

| Transmission Medium | Oil |

| Discharge Capacity | 8 ml/min |

| Maximum Discharge Pressure | 15 kgf/cm² |

| Capacity | 500 CC |

| Discharge Port | Two ports (Left & Right) |

| Weight | 949 g |

| Package Dimensions | 23 x 17 x 14 cm |

| Model Number | MUNEFEgpayxn7zse |

| ASIN | B0D9BWH3XF |

3. Package Contents

The package includes the following items:

- 1 x Manual Lubrication Pump

Note: The manufacturer states that new and old types of this product may be sent randomly.

4. Setup and Installation

Proper setup is crucial for the optimal performance and longevity of your manual lubricating oil pump. Follow these steps for installation:

- Choose Mounting Location: Select a stable and accessible location on or near the machinery that requires lubrication. Ensure the pump is positioned vertically as per its design.

- Secure the Pump: Use appropriate fasteners (not included) to securely mount the pump to the chosen surface. Ensure it is firmly attached to prevent movement during operation.

- Connect Outlet Hoses: Connect the lubrication hoses (not included) to the two discharge ports (left and right) of the pump. Ensure connections are tight to prevent leaks.

- Route Hoses: Route the hoses to the lubrication points on your machinery. Ensure hoses are not kinked or obstructed.

- Fill with Lubricant: Unscrew the top cap of the pump reservoir. Carefully pour the appropriate lubricating oil (viscosity N20-N1000) into the reservoir. Do not overfill. Replace the cap securely.

- Initial Priming (Optional): Before first use, you may need to operate the handle a few times to prime the pump and ensure oil flows through the system.

Figure 4.1: Top view of the pump with the cap and filter removed, illustrating the reservoir opening for filling lubricant.

Figure 4.2: Detail of the brass fitting, which serves as an outlet port for lubrication.

5. Operating Instructions

The manual lubricating oil pump is designed for straightforward operation. Follow these steps to lubricate your machinery:

- Check Oil Level: Before operation, visually inspect the oil level through the transparent sight glass on the side of the pump. Refill if necessary (refer to Section 4).

- Operate the Handle: Grasp the pump handle firmly.

- Push Down: Push the handle down to its full extent. This action expels oil from the cylinder through the discharge ports to the lubrication points.

- Release: Release the handle. The spring mechanism will pull the plunger back, drawing more oil into the cylinder from the reservoir.

- Repeat: Repeat steps 3 and 4 as many times as required to deliver the desired amount of lubricant to your machinery. The discharge capacity is approximately 8 ml per stroke.

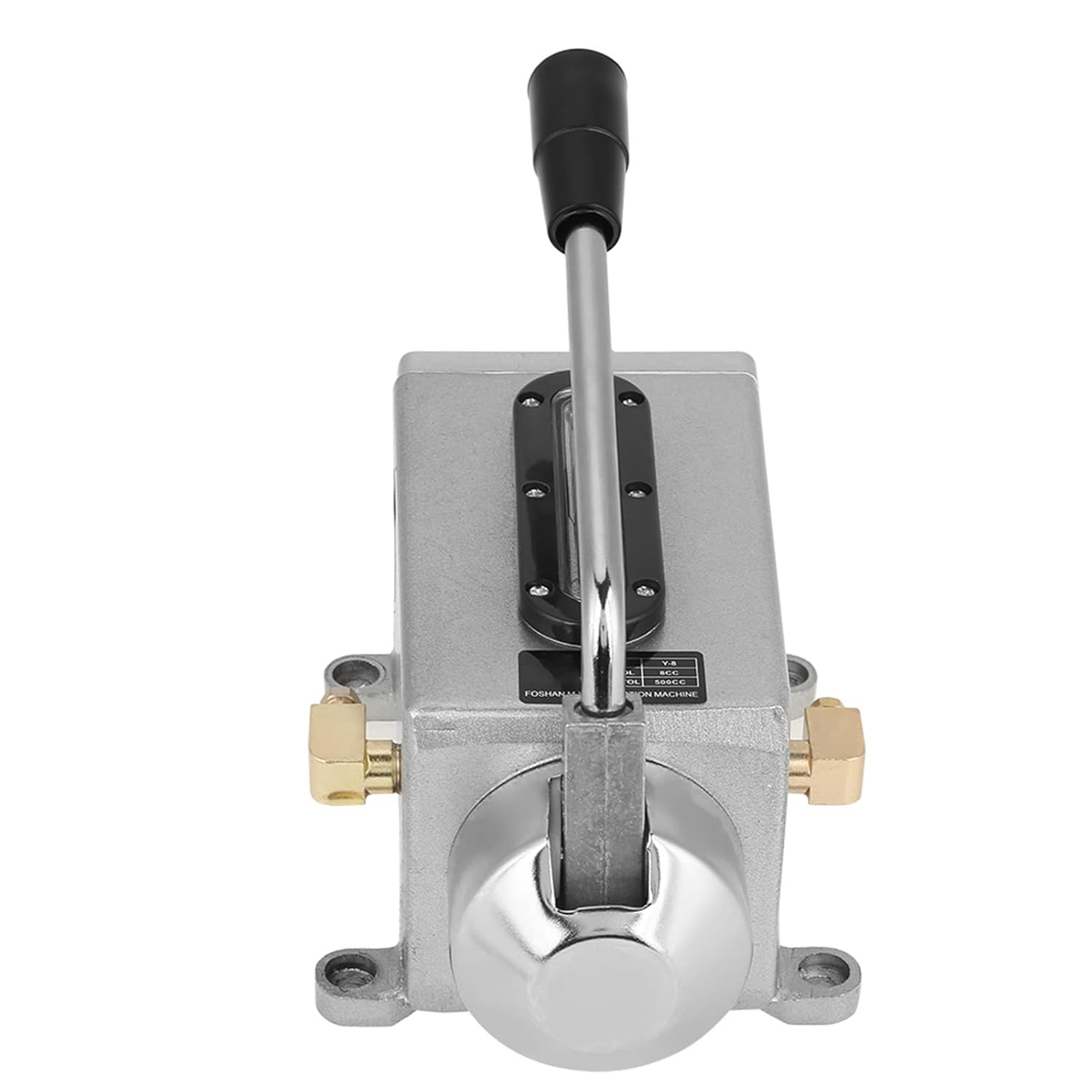

Figure 5.1: The manual oil pump, showing the handle used for operation.

Figure 5.2: View illustrating the dual discharge ports and the handle mechanism.

6. Maintenance

Regular maintenance ensures the longevity and reliable performance of your lubricating oil pump.

- Oil Level Check: Routinely check the oil level in the reservoir using the sight glass. Refill promptly when low to prevent air from entering the system.

- Lubricant Quality: Always use clean, high-quality lubricating oil within the recommended viscosity range (N20-N1000). Contaminated oil can damage the pump and the machinery it lubricates.

- Cleanliness: Keep the exterior of the pump clean. Wipe away any spilled oil immediately to prevent accumulation of dirt and debris.

- Check for Leaks: Periodically inspect all connections and seals for any signs of oil leakage. Tighten connections or replace seals if leaks are detected. The pump is designed with high-quality seals to minimize leakage, but regular checks are still important.

- Filter Inspection: If your pump model includes an internal filter (as shown in some images), periodically inspect and clean or replace it to ensure proper oil flow and prevent contaminants from reaching the pump mechanism.

Figure 6.1: View showing the internal filter, which should be inspected during maintenance.

7. Troubleshooting

If you encounter issues with your manual lubricating oil pump, refer to the following common problems and their solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| No oil discharge or low pressure |

|

|

| Oil leakage from pump |

|

|

| Handle is stiff or difficult to operate |

|

|

8. Warranty and Support

For information regarding warranty coverage, technical support, or replacement parts, please refer to the seller's information on the product purchase page or contact the manufacturer directly. Keep your purchase receipt as proof of purchase.

Manufacturer: MUNEFE

9. Product Images