1. Introduction

The Creality Hyper PLA Filament is designed for high-speed 3D printing, offering enhanced fluidity and rapid cooling properties. This filament is made from Polylactic Acid (PLA), a biodegradable thermoplastic derived from renewable resources like corn starch. It features a 1.75mm diameter with a dimensional accuracy of ±0.02mm, ensuring stable extrusion and consistent print quality. This manual provides essential information for the proper use, maintenance, and troubleshooting of your Creality Hyper PLA Filament.

Image 1.1: Creality Hyper PLA Filament Rainbow 1.75mm spool with a sample 3D print.

Image 1.2: Overview of Creality Hyper PLA features.

2. Setup

Before beginning your 3D printing project, ensure the filament is properly prepared and loaded into your printer.

2.1 Unpacking the Filament

The Creality Hyper PLA Filament comes in a vacuum-sealed nylon bag with desiccants to protect it from moisture. Carefully open the packaging and remove the spool.

Image 2.1: Packaging of Creality Hyper PLA Filament.

2.2 Loading the Filament

Refer to your 3D printer's specific instructions for loading filament. Generally, the process involves:

- Mounting the spool onto the printer's spool holder.

- Feeding the filament through the extruder mechanism.

- Heating the hot end to the recommended temperature (see Section 3.1).

- Extruding a small amount of filament to ensure smooth flow and remove any old material.

This filament is universally compatible with most 1.75mm FDM 3D printers, including Creality, Ender, Anycubic, Elegoo, Bambu, Ankermake, Prusa, Flashforge, Monoprice, FLSUN, Artillery, and Qidi models.

3. Operating Instructions

Optimal printing results depend on correct parameter settings for your 3D printer.

3.1 Recommended Printing Parameters

- Nozzle Temperature: 190-230°C

- Bed Temperature: 30-60°C (or off)

- Printing Speed: 30-600mm/s

Adjust these settings based on your specific printer model and desired print quality. For high-speed printing, ensure your printer is capable of maintaining consistent extrusion and rapid cooling.

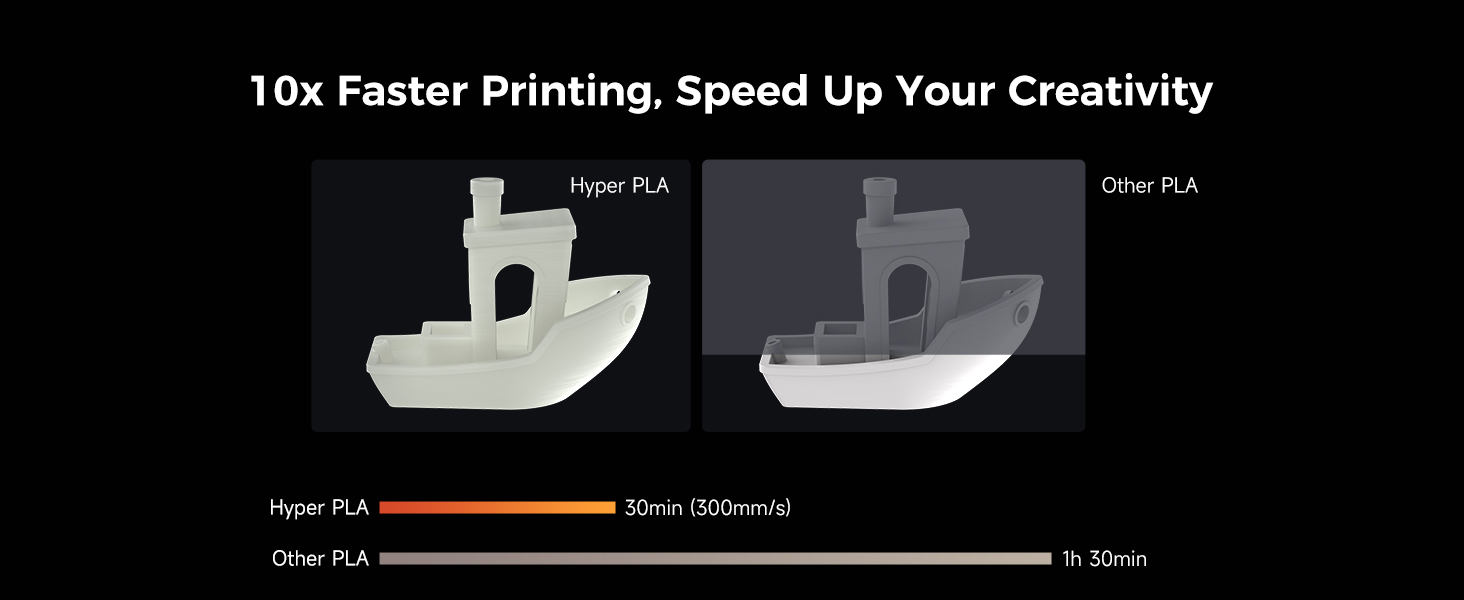

Image 3.1: Illustration of Hyper PLA's faster printing speed.

Image 3.2: Demonstrating precision during high-speed printing.

3.2 Material Properties

Creality Hyper PLA offers improved toughness and strength compared to traditional PLA, making it suitable for functional parts and models requiring better structural integrity.

Image 3.3: Example of a strong, functional part printed with Hyper PLA.

Image 3.4: Applications of Hyper PLA for functional parts, mass production, prototyping, and toys.

4. Maintenance

Proper storage and handling are crucial for maintaining filament quality.

4.1 Storage

Store the filament in a cool, dry place, ideally in its original vacuum-sealed bag with desiccants when not in use. Exposure to humidity can degrade PLA, leading to poor print quality and extrusion issues.

4.2 Filament Winding

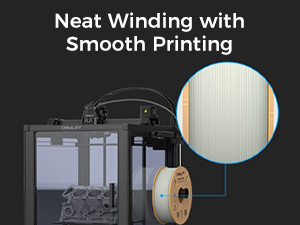

The filament is neatly wound to prevent tangles and ensure smooth feeding during printing.

Image 4.1: Neat filament winding for smooth printing.

5. Troubleshooting

If you encounter issues during printing, consider the following common problems and solutions:

- Poor Adhesion/Warping: Ensure your print bed is clean and level. Adjust bed temperature within the recommended range (30-60°C). Consider using an adhesive if necessary.

- Clogging/Under-extrusion: Check nozzle temperature and increase it slightly if the filament is not flowing smoothly. Ensure the filament path is clear and the nozzle is not partially blocked. Verify the filament diameter is consistent.

- Stringing/Oozing: Reduce nozzle temperature slightly or increase retraction settings in your slicer software.

- Brittle Filament: This often indicates moisture absorption. Dry the filament using a filament dryer or by baking it at a low temperature (e.g., 45-50°C for 4-6 hours) before use.

Image 5.1: Verifying uniform wire diameter for stable extrusion.

Image 5.2: Filament diameter measurement for quality control.

6. Specifications

| Specification | Value |

|---|---|

| Material | Polylactic Acid (PLA) |

| Color | Rainbow (Springlake) |

| Filament Diameter | 1.75 mm |

| Dimensional Accuracy | ±0.02 mm |

| Net Weight | 1 KG (2.2 lbs) |

| Recommended Nozzle Temperature | 190-230°C |

| Recommended Bed Temperature | 30-60°C (or off) |

| Printing Speed | 30-600 mm/s |

| Manufacturer Part Number | AMUS-HYZ-HyperPLA-SpringLake-US |

Image 6.1: Key features of Creality Hyper PLA Filament.

7. Environmental Information

Creality Hyper PLA Filament is made from eco-friendly materials and comes in recyclable packaging, contributing to reduced carbon emissions.

Image 7.1: PLA production from corn starch.

Image 7.2: Eco-friendly packaging and materials.

8. Warranty and Support

For warranty information, technical support, or further inquiries regarding your Creality Hyper PLA Filament, please refer to the official Creality website or contact Creality customer service. You can find more information and support resources at qr.creality.com.