1. Product Overview

This manual provides essential information for the safe and efficient operation of your JJCEQBPE 3/4" IP65 Two Way Waterproof Motorized Ball Valve. This electric ball valve is designed for controlling the flow of cold/hot water and 60% Ethylene Glycol solutions in various applications.

Image 1.1: The JJCEQBPE 3/4" IP65 Two Way Waterproof Motorized Ball Valve, showcasing its compact design and brass body.

Key features include:

- Two-Way Operation: Designed for efficient flow control in two directions.

- Durable Construction: Made from high-quality brass for longevity.

- IP65 Waterproof Rating: Suitable for outdoor and humid environments.

- Motorized Control: Features an electric motor for automated opening and closing.

2. Specifications

| Parameter | Value |

|---|---|

| Medium | Cold/hot water, 60% Ethylene Glycol |

| Material | Brass |

| Power Supply | AC220V (for this model), DC12V, DC24V (other variants) |

| Structure Forms | Two Ways |

| Operation Mode | Three Wire Two Ways Control / Three-wire One Control mode / 2-wire (power-off reset mode) |

| Power Consumption | 6W (only when valve opens/closes) |

| Running Time | 5-15 Seconds |

| Nominal Pressure | 1.6MPa |

| Medium Temperature | Up to 295°F (146°C) |

| Maximum Differential Pressure | 1.0MPa |

| Connection Mode | G Internal Thread (3/4" for this model) |

| Torque | 8 N.M (for AC220V), 6 N.M (for DC12/24V) |

| Waterproof Level | IP65 |

| Item Weight | 7.1 ounces |

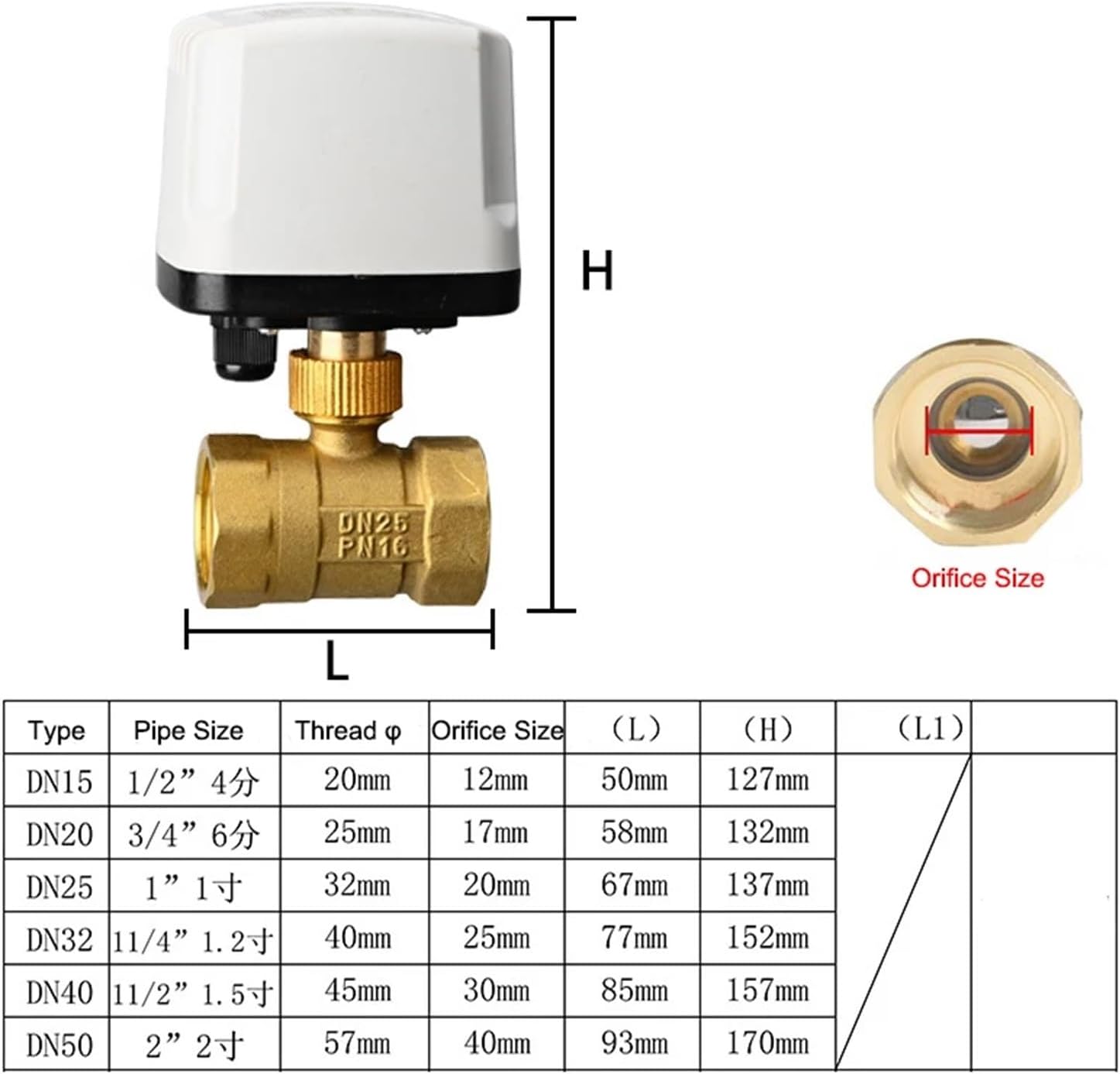

Image 2.1: Dimensional drawing and size chart for various valve types, including pipe size, thread, orifice size, length (L), and height (H).

Image 2.2: Illustration highlighting the IP65 waterproof rating, indicating suitability for humid environments.

Image 2.3: Detailed views of the valve's internal components, including the brass body, double-layer motor with 8 N.M torque and metal limit switch, and the strong metal connecting shaft.

3. Installation and Setup

Before installation, ensure the power supply is disconnected. This valve is designed for G internal thread connections. Ensure proper sealing to prevent leaks.

3.1 Wiring Diagram (CR03 Model)

The AC220V_CR03 model uses a three-wire one-control mode. Refer to the diagram below for correct wiring.

Image 3.1: Wiring diagram for CR03 models (AC220V, DC12V, DC24V). It illustrates the connection of the brown, blue, and yellow lines from the actuator to an external controller with a switch (SW).

Wiring Instructions:

- Connect the Brown line to one side of the power supply and the switch (SW).

- Connect the Blue line to the other side of the power supply.

- Connect the Yellow line to the switch (SW) to control the valve's state.

Operation based on SW state:

- When SW is closed, the valve opens. The internal automatic power-off function activates once fully open, and the valve remains in the fully open position.

- When SW is disconnected, the valve closes. The internal automatic power-off function activates once fully closed, and the valve remains in the fully closed position.

Warning: Ensure all electrical connections are secure and comply with local electrical codes. Incorrect wiring can damage the device or cause electrical hazards.

4. Operating Instructions

Once installed and wired correctly, the valve's operation is controlled by the external switch (SW) as described in the wiring section.

- To open the valve, close the control switch (SW). The valve will automatically open within 5-15 seconds and then power off, holding its open position.

- To close the valve, open (disconnect) the control switch (SW). The valve will automatically close within 5-15 seconds and then power off, holding its closed position.

The valve is designed for intermittent operation, consuming power only during the opening or closing cycle.

5. Maintenance

The JJCEQBPE Motorized Ball Valve is designed for low maintenance. Regular checks can ensure optimal performance and longevity.

- Visual Inspection: Periodically inspect the valve and connections for any signs of leaks, corrosion, or physical damage.

- Electrical Connections: Ensure all wiring connections remain secure and free from moisture or damage.

- Cleaning: If installed in a dusty or dirty environment, gently clean the exterior of the actuator and valve body with a damp cloth. Do not use abrasive cleaners or solvents.

- Operational Check: Occasionally cycle the valve (open and close) to ensure smooth operation.

Caution: Always disconnect power before performing any maintenance or inspection.

6. Troubleshooting

If you encounter issues with your motorized ball valve, refer to the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | No power; Incorrect wiring; Motor malfunction; Obstruction in valve | Check power supply; Verify wiring against diagram (Image 3.1); Inspect for obstructions; Contact support if motor is faulty. |

| Valve leaks | Improper installation; Damaged seals; Incorrect thread sealant | Ensure connections are tight and properly sealed; Inspect seals for damage; Reapply thread sealant if necessary. |

| Valve operates slowly | Low voltage; Internal friction | Verify power supply voltage matches valve requirements; Cycle valve a few times to see if operation improves. |

For issues not listed here or if solutions do not resolve the problem, please contact the manufacturer's support.

7. Warranty and Support

Warranty information for the JJCEQBPE 3/4" IP65 Two Way Waterproof Motorized Ball Valve is typically provided by the manufacturer or seller at the time of purchase. Please refer to your purchase documentation for specific warranty terms and conditions.

For technical support, troubleshooting assistance, or warranty claims, please contact JJCEQBPE customer service through the platform where the product was purchased or refer to the contact information provided with your product packaging.