1. Introduction

This user manual provides comprehensive instructions for the safe and efficient operation, setup, and maintenance of your VEVOR MT-30 Manual Round Bottle Labeling Machine. Please read this manual thoroughly before using the machine to ensure proper function and to prevent damage or injury. Keep this manual for future reference.

The VEVOR MT-30 is designed for applying labels to round bottles, offering a manual, non-electric solution for small to medium-scale labeling needs. It is engineered for quick and precise label application, minimizing bubbles and ensuring a professional finish.

2. Safety Instructions

Always follow basic safety precautions when operating any machinery. Failure to do so may result in personal injury or damage to the equipment.

- Read and understand all instructions before operation.

- Ensure the machine is placed on a stable, level surface to prevent tipping.

- Keep hands and loose clothing away from moving parts during operation.

- Do not attempt to modify the machine. Use only original VEVOR parts for replacement.

- Keep the work area clean and well-lit.

- This machine is designed for applying labels to round bottles only. Do not use it for other purposes.

- Store the machine in a dry, safe place when not in use.

3. Product Overview

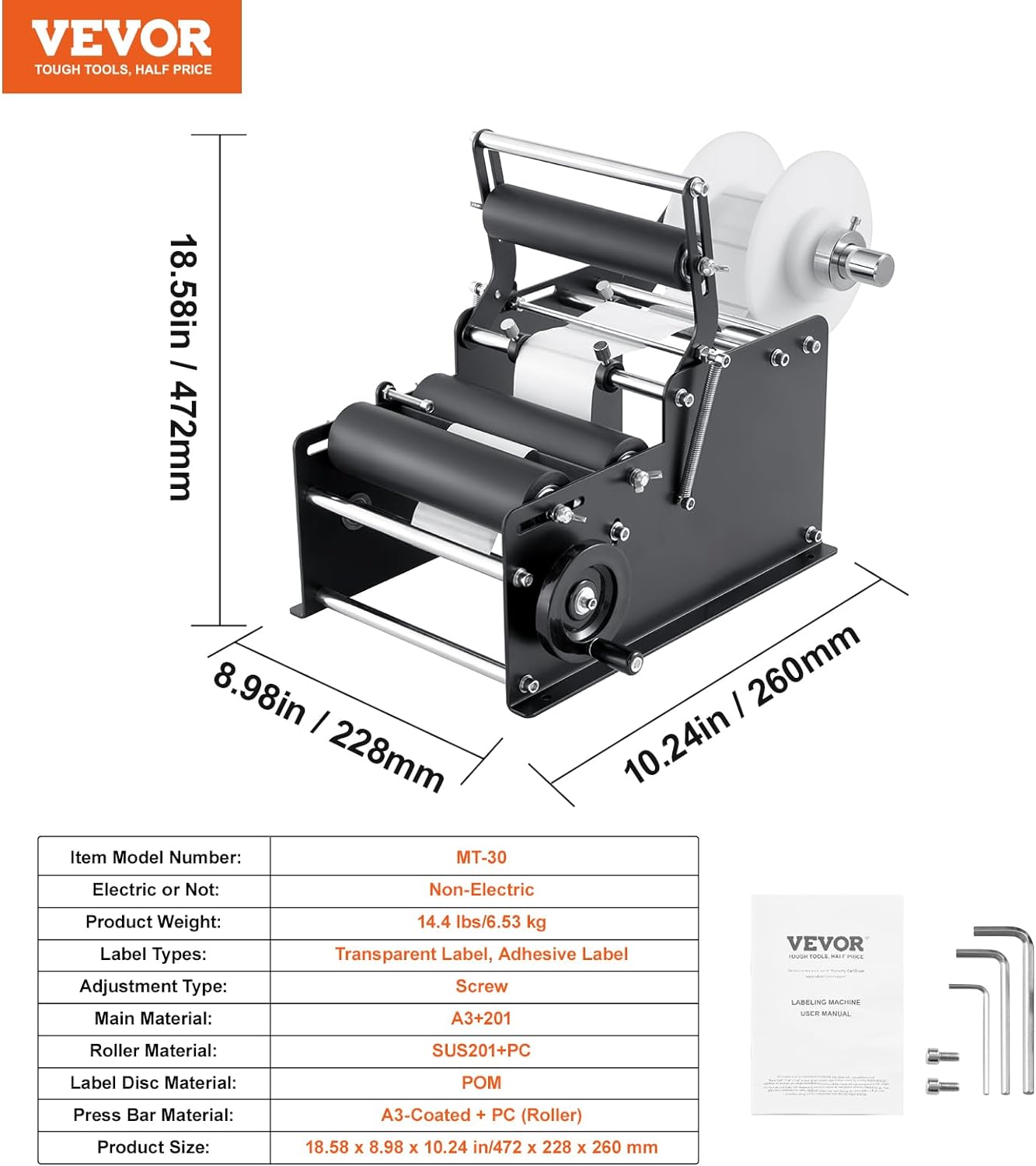

The VEVOR MT-30 Manual Round Bottle Labeling Machine is constructed from durable A3 and 201 stainless steel, featuring SUS201+PC rollers and a POM label disc. It is designed for efficient and bubble-free label application.

3.1 Key Features

- Efficient Labeling: Capable of labeling 15 to 20 bottles per minute, significantly reducing manual labeling time.

- Bubble-Free Application: Equipped with a round pressure bar and rubber roller system to ensure smooth, tight, and bubble-free label adhesion.

- Adjustable Versatility: Easily adjustable to accommodate round bottles with diameters ranging from 20 mm (0.78 inches) to 120 mm (4.72 inches).

- Durable Construction: Made from high-quality A3 and 201 stainless steel, ensuring longevity and resistance to rust.

- User-Friendly Design: Features an intuitive manual adjustment system for quick label changes and compatibility with various label sizes.

- Label Compatibility: Supports both transparent and adhesive labels.

3.2 Package Contents

- 1 x VEVOR MT-30 Manual Round Bottle Labeling Machine

- Necessary assembly tools (e.g., Allen wrenches)

- User Manual

4. Setup and Assembly

The VEVOR MT-30 machine requires minimal assembly. Follow these steps to set up your labeling machine:

- Unpack Components: Carefully remove all parts from the packaging. Verify that all components listed in Section 3.2 are present.

- Secure Base: Place the main base of the machine on a stable, flat workbench.

- Install Label Roll Holder: Attach the label roll holder assembly to the designated slots on the machine's frame. Ensure it is securely fastened with the provided screws or knobs.

- Install Rollers and Pressure Bar: Position the rubber rollers and the round bottle press bar into their respective mounts. Ensure they can move freely and are properly aligned.

- Adjustments: Familiarize yourself with the adjustment screws for label width, length, and bottle diameter. These will be fine-tuned during operation.

5. Operating Instructions

Follow these steps for effective and precise label application:

- Load Label Roll:

- Place your roll of labels onto the label disc holder. Ensure the label roll's inner diameter is at least 25 mm (0.98 inches) and the outer diameter does not exceed 180 mm (7.09 inches).

- Thread the leading edge of the label strip through the guide rollers and under the round bottle press bar, ensuring it is aligned straight.

Figure 3: Label roll specifications and compatibility with various label types. - Adjust Label Dimensions:

- Use the screw adjustments to set the label width (0.39-5.12 inches / 10-130 mm) and label length (0.39-11.81 inches / 10-300 mm) according to your label specifications.

- These adjustments ensure the label is dispensed correctly and precisely.

Figure 4: Detailed view of the screw adjustment for label dimensions. - Adjust for Bottle Size:

- Place a bottle onto the machine's bottle support.

- Adjust the forward and backward rollers to securely hold the bottle and ensure the label will be applied centrally and smoothly. The machine accommodates round bottles with diameters from 20 mm (0.78 inches) to 120 mm (4.72 inches).

Figure 5: Adjusting rollers to fit different bottle diameters. - Apply Label:

- With the bottle in place and adjustments made, turn the hand crank. This action will rotate the bottle and dispense the label, applying it smoothly and evenly.

- The unique round bottle press bar ensures tight, bubble-free labeling.

Figure 6: Applying a label using the machine's hand crank and press bar. - Remove Labeled Bottle: Once the label is applied, carefully remove the bottle and repeat the process for the next one.

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your VEVOR MT-30 labeling machine.

- Cleaning: After each use, wipe down the machine with a soft, dry cloth to remove any dust, label residue, or adhesive. For stubborn residue, use a mild, non-abrasive cleaner.

- Lubrication: Periodically apply a small amount of machine oil to moving parts, such as the roller axles and adjustment screws, to ensure smooth operation.

- Inspection: Regularly inspect all screws, bolts, and moving parts for tightness and wear. Tighten any loose fasteners. Replace any worn or damaged components immediately.

- Storage: When not in use, store the machine in a clean, dry environment, protected from dust and extreme temperatures.

7. Troubleshooting

This section addresses common issues you might encounter with your labeling machine.

| Problem | Possible Cause | Solution |

|---|---|---|

| Labels are crooked or misaligned. |

|

|

| Labels have bubbles or wrinkles. |

|

|

| Labels are not dispensing. |

|

|

| Machine feels stiff or difficult to operate. |

|

|

8. Specifications

Detailed technical specifications for the VEVOR MT-30 Manual Round Bottle Labeling Machine:

| Parameter | Value |

|---|---|

| Model Number | MT-30 |

| Operation Type | Manual, Non-Electric |

| Product Weight | 6.53 kg (14.4 lbs) |

| Label Types Supported | Transparent, Adhesive Labels |

| Adjustment Type | Screw Adjustment |

| Main Material | A3 + 201 Stainless Steel |

| Roller Material | SUS201 + PC |

| Label Disc Material | POM |

| Press Bar Material | A3 Coated + PC (Roller) |

| Product Dimensions (L x W x H) | 472 x 228 x 260 mm (18.58 x 8.98 x 10.24 inches) |

| Applicable Label Width | 10-130 mm (0.39-5.12 inches) |

| Applicable Label Length | 10-300 mm (0.39-11.81 inches) |

| Label Roll Inner Diameter | ≥ 25 mm (≥ 0.98 inches) |

| Applicable Round Bottle Diameter | 20-120 mm (0.78-4.72 inches) |

| Labeling Speed | 15-20 pieces/min (approximate) |

9. Warranty and Support

Information regarding product warranty and customer support was not available in the provided data. For warranty details, technical assistance, or to inquire about replacement parts, please contact VEVOR customer service directly or visit their official website. Ensure you have your product model number (MT-30) and purchase information ready when contacting support.

You can often find support information on the official VEVOR website: www.vevor.com