1. Introduction

Thank you for choosing the Yato YT-81980 Diamond Core Drill. This manual provides essential information for the safe and effective operation, maintenance, and troubleshooting of your new tool. Please read this manual thoroughly before use and keep it for future reference. This diamond core drilling machine is designed for a range of applications, including drilling holes in stone, concrete, brickwork, porcelain, tiles, and glass.

2. Safety Instructions

Always prioritize safety when operating power tools. Failure to follow these instructions may result in electric shock, fire, and/or serious injury.

General Safety

- Work Area Safety: Keep the work area clean and well-lit. Cluttered or dark areas invite accidents. Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust.

- Electrical Safety: Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, and refrigerators.

- Personal Safety: Always wear appropriate personal protective equipment (PPE), including eye protection, hearing protection, and sturdy work gloves. Dress properly; avoid loose clothing or jewelry that can get caught in moving parts.

- Tool Use and Care: Do not force the power tool. Use the correct power tool for your application. Disconnect the plug from the power source before making any adjustments, changing accessories, or storing power tools.

Specific Diamond Core Drill Safety

- Water Cooling: This tool requires water cooling for diamond core bits. Ensure a continuous water supply during operation to prevent overheating of the bit and material.

- GFCI Protection: Always use a Ground Fault Circuit Interrupter (GFCI) when operating this tool, especially when working with water. This provides crucial protection against electric shock.

Image: Ground Fault Circuit Interrupter (GFCI) plug. Always use a GFCI for electrical safety, especially when operating the drill with water.

- Secure Mounting: When using the drill stand, ensure it is securely anchored to the work surface to prevent movement during drilling.

- Clutch Operation: The machine is equipped with a clutch. Familiarize yourself with its operation. It is designed to prevent sudden jerks if the drill bit binds, enhancing user safety.

- Material Stability: Ensure the material being drilled is stable and properly supported.

3. Product Overview

The Yato YT-81980 is a powerful diamond core drilling machine designed for precision drilling in various hard materials. It can be used handheld or mounted on its included stand.

Key Features

- Universal diamond core drilling machine for handheld or fixed work.

- Powerful 2200W motor with a speed range of 0-1200 RPM.

- Enables drilling holes in a wide range, from 30mm to 180mm.

- Equipped with a safety clutch for smooth operation, preventing jerks when drilling in reinforced concrete.

- Standard 1 1/4" Inch drill chuck, compatible with most core bits on the market.

- Includes a robust tripod stand with gear mechanism for effortless drilling in hard materials.

Components

Image: The Yato YT-81980 Diamond Core Drill main unit, showing the motor housing, handles, and chuck.

Image: The Yato YT-81980 Diamond Core Drill mounted on its included stand, ready for fixed operation.

Image: Spanner wrench, used for securely attaching and detaching diamond core bits.

4. Setup

4.1 Assembling the Drill Stand

- Unpack all components: drill unit, stand base, vertical column, feed handle, and mounting hardware.

- Attach the vertical column to the stand base using the provided bolts and nuts. Ensure it is firmly secured.

- Mount the drill unit onto the carriage of the vertical column. Secure it using the appropriate clamps or bolts, ensuring the drill is stable and aligned.

- Attach the feed handle to the gear mechanism on the carriage.

Image: The Yato YT-81980 Diamond Core Drill fully assembled on its stand, showing the feed handle and stable base.

4.2 Attaching the Diamond Core Bit

- Ensure the drill is unplugged from the power source.

- The drill features a standard 1 1/4" Inch chuck. Select a diamond core bit appropriate for your drilling material and desired diameter (30mm to 180mm).

- Thread the core bit onto the chuck spindle. Use the provided spanner wrench to tighten it securely. Do not overtighten.

4.3 Water Supply Connection

- Locate the water coupling port on the drill unit (1/2" or 12.5mm connection).

- Connect a suitable water hose to this port. Ensure the connection is secure and leak-free.

- Ensure a clean water source is available and ready to be turned on before drilling.

4.4 Power Connection

- Ensure the drill's power switch is in the 'OFF' position.

- Plug the drill into a suitable power outlet (230V~ 50Hz). Always use a Ground Fault Circuit Interrupter (GFCI) for safety.

5. Operating Instructions

5.1 Preparing for Drilling

- Mark the exact drilling location on your material.

- If using the stand, securely anchor the stand to the work surface to prevent movement.

- Position the drill bit directly over the marked center point.

- Turn on the water supply to ensure a steady flow to the drill bit.

5.2 Drilling Procedure

- Switch the drill to the 'ON' position. The motor will start, and the drill bit will begin to rotate.

- Slowly and steadily apply pressure to the drill using the feed handle (for stand-mounted operation) or by hand (for handheld operation). Avoid excessive force, especially at the start of drilling.

- Maintain a consistent feed rate. Allow the diamond segments to cut the material. The water flow will cool the bit and flush away debris.

- The drill's clutch will engage if the bit binds or encounters excessive resistance, preventing sudden rotation of the tool. Reduce pressure if the clutch engages frequently.

- Continue drilling until the desired depth is reached or the core passes through the material.

- Once drilling is complete, withdraw the drill bit from the hole.

- Switch the drill to the 'OFF' position and turn off the water supply.

5.3 Post-Drilling

- Carefully remove the core from the drill bit or the drilled material.

- Clean the drill bit and the work area.

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your Yato YT-81980 Diamond Core Drill.

- Cleaning: After each use, clean the drill unit, stand, and core bits. Remove any dust, slurry, or debris. Use a damp cloth; do not use harsh chemicals or solvents.

- Inspection: Regularly inspect the power cord for damage, cuts, or fraying. Check the chuck for wear and ensure it tightens securely. Inspect the stand for any loose bolts or signs of damage.

- Lubrication: Refer to the manufacturer's guidelines for any specific lubrication points on the gear mechanism of the stand.

- Storage: Store the drill and its components in a clean, dry place, away from direct sunlight and extreme temperatures.

- Service: Any repairs or internal maintenance should be performed by qualified service personnel.

7. Troubleshooting

This section addresses common issues you might encounter with your diamond core drill.

Problem: Drill does not start.

- Possible Cause: No power supply. Solution: Check if the power cord is securely plugged in. Test the outlet with another device. Check the GFCI for tripping and reset if necessary.

- Possible Cause: Faulty power switch. Solution: Contact qualified service personnel.

Problem: Drill bit overheats or wears quickly.

- Possible Cause: Insufficient water cooling. Solution: Ensure a continuous and adequate flow of water to the drill bit during operation. Check for kinks in the water hose or blockages in the water coupling.

- Possible Cause: Excessive feed pressure. Solution: Reduce the feed pressure. Allow the diamond segments to do the cutting.

- Possible Cause: Incorrect bit for material. Solution: Ensure you are using a diamond core bit suitable for the material being drilled.

Problem: Drill binds or clutch engages frequently.

- Possible Cause: Excessive feed pressure. Solution: Reduce the feed pressure.

- Possible Cause: Bit is dull or damaged. Solution: Replace the diamond core bit.

- Possible Cause: Material is unstable or contains rebar. Solution: Ensure the material is securely clamped. Proceed with caution if drilling through reinforced concrete.

For issues not covered here, please contact Yato customer support or a qualified service center.

8. Specifications

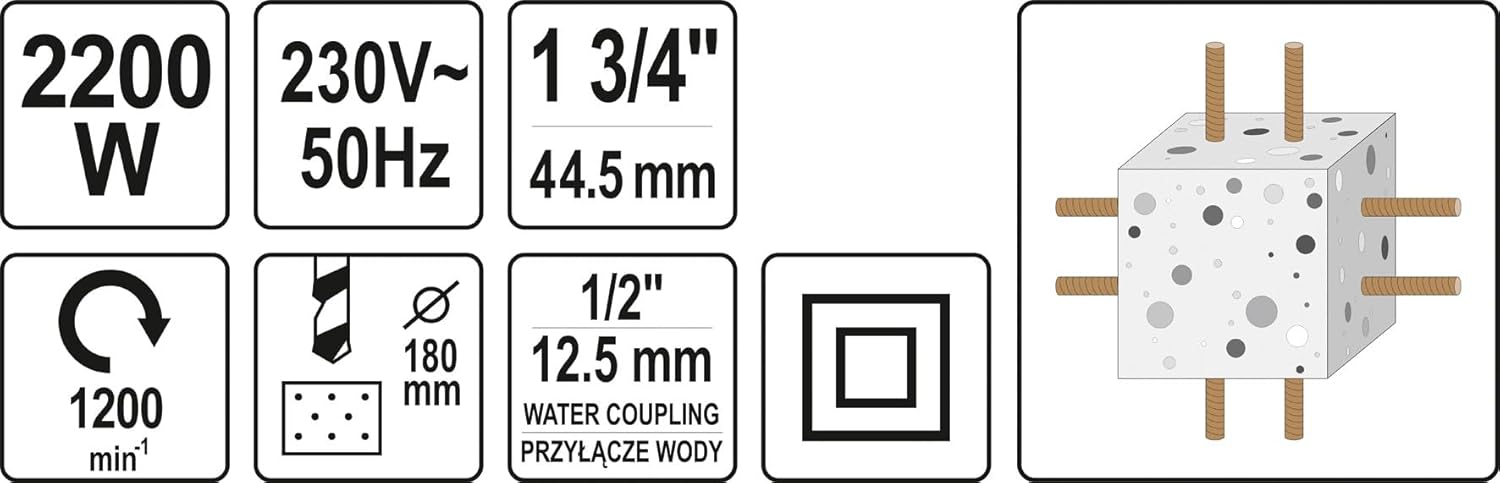

The following are the technical specifications for the Yato YT-81980 Diamond Core Drill:

Image: Product packaging displaying key specifications of the Yato YT-81980 Diamond Core Drill.

Image: Detailed diagram illustrating the technical specifications and features of the Yato YT-81980 Diamond Core Drill.

| Specification | Value |

|---|---|

| Brand | Yato |

| Model Number | YT-81980 |

| Power Source | Corded Electric |

| Voltage | 230V~ 50Hz |

| Maximum Power | 2200 Watts |

| Maximum Rotational Speed | 1200 RPM |

| Amperage | 10 Amps |

| Drill Type | Diamond Core Drill |

| Chuck Size | 1 1/4" Inch (44.5 mm) |

| Drilling Range | 30mm to 180mm |

| Water Coupling | 1/2" (12.5 mm) |

| Included Components | Stand |

9. Warranty and Support

Yato products are manufactured to high-quality standards. For warranty information, please refer to the documentation included with your purchase or visit the official Yato website. For technical support, service, or spare parts, please contact your local Yato dealer or authorized service center.

You can also find more information and support by scanning the QR code or visiting the link below: