Introduction

The 3M Cubitron 3 Depressed Center Grinding Wheel is engineered for demanding applications, offering superior performance in heavy weld removal and other rigorous grinding tasks. This wheel features 3M's precision-shaped ceramic grain, designed for exceptionally fast cutting and extended durability. It is suitable for use on a wide range of materials, with specific formulation for stainless steel, mild steel, and aerospace alloys.

Image: Front view of the 3M Cubitron 3 Depressed Center Grinding Wheel, highlighting its purple color and central hub. The wheel is labeled with "3M Cubitron 3" and model number 90007, along with size specifications (5 in x 1/4 in x 7/8 in) and maximum RPM (12,250).

Safety Information

WARNING: Always read and understand all safety instructions before using this product. Failure to follow these instructions can result in serious injury or death.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including eye protection (safety glasses and face shield), hearing protection, respiratory protection, and heavy-duty gloves.

- Tool Compatibility: Ensure the grinding wheel is compatible with your angle grinder in terms of size, arbor hole, and maximum RPM. Never exceed the maximum RPM marked on the wheel.

- Inspection: Before each use, inspect the grinding wheel for any signs of damage, cracks, chips, or excessive wear. Do not use a damaged wheel.

- Proper Mounting: Ensure the wheel is correctly mounted and securely tightened on the grinder's arbor. Follow the grinder manufacturer's instructions for wheel installation.

- Workpiece Security: Secure the workpiece firmly to prevent movement during grinding.

- Work Area: Ensure your work area is clear of obstructions, well-lit, and properly ventilated. Keep bystanders away.

- Legal Disclaimer: 3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. These products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert. For additional product information, visit www.3M.com.

Product Features

The 3M Cubitron 3 Grinding Wheel incorporates advanced abrasive technology for superior performance:

- Heavy-Duty Performance: Specifically designed for heavy weld removal and other demanding grinding applications across various materials, including stainless steel, mild steel, and aerospace alloys.

- Enhanced Speed: Delivers up to a 15% increased cut rate compared to 3M Cubitron II Performance Abrasives, reducing the time and pressure required for tasks.

- Fewer Changeovers: Capable of removing up to 1.5 times more material than 3M Cubitron II Performance Abrasives, leading to increased productivity and less downtime.

- Long Lasting: Engineered for extended lifespan, outperforming many leading competitors in durability.

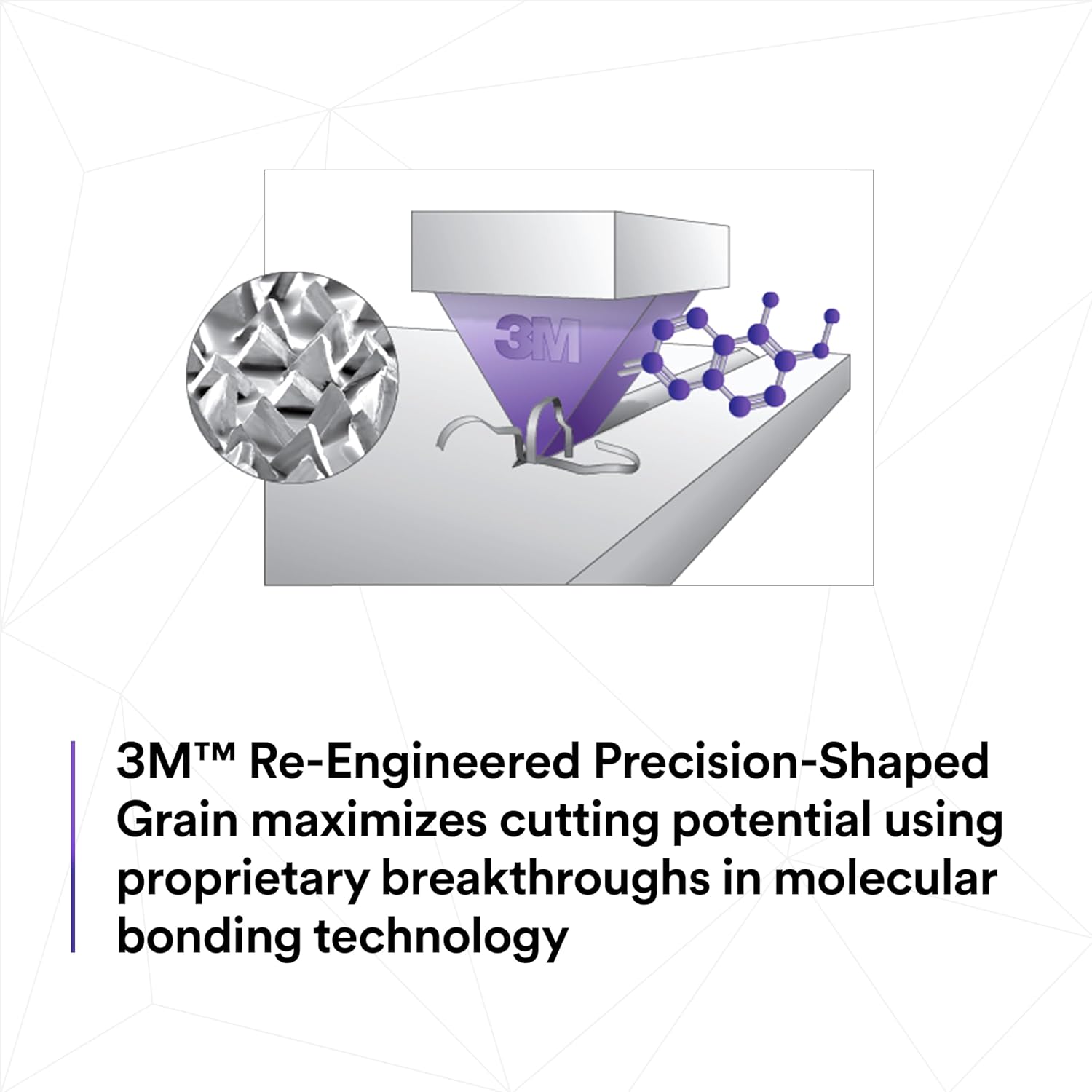

- 3M Re-Engineered Precision-Shaped Grain: Utilizes a breakthrough proprietary molecular bonding technology. This design features sharp, angular structures that continuously fracture to form new sharp points, ensuring even wear, cooler operation, and optimized mineral breakdown for consistent performance.

Image: A diagram showing the 3M Re-Engineered Precision-Shaped Grain. It depicts how the sharp, angular abrasive grains fracture during use to expose new cutting edges, ensuring consistent performance and extended life.

Image: The 3M Cubitron 3 Grinding Wheel with text overlay stating it delivers up to 14% faster cut rate compared to 3M Cubitron II Depressed Center Grinding Wheels. The wheel's specifications are visible.

Specifications

| Attribute | Detail |

|---|---|

| Product Dimensions | 5 x 0.13 x 0.1 inches (5"L x 0.13"W) |

| Item Model Number | 90007 |

| Weight | 4.42 Pounds |

| Grit Material | Ceramic |

| Grit Type | Medium (36+) |

| Compatible Devices | Angle Grinder |

| Attachment Types | Center hole, Threaded 5/8 in - 11 |

| Diameter Options | 4 in (100 mm), 4.5 in (115 mm), 5 in (125 mm), 6 in (150 mm), 7 in (180 mm), 9 in (230 mm) |

| Thickness | 1/4 in (6 mm) |

| Center Hole Diameter Options | 3/8 in (9.53 mm), 5/8 in (15.88 mm), 7/8 in (22.23 mm) |

| What's in the Box | Abrasive Disc |

Image: A detailed table outlining the attachment types, diameter options, thickness, center hole diameter options, and grit for the 3M Cubitron 3 Depressed Center Grinding Wheels.

Setup

- Unpacking: Carefully remove the grinding wheel from its packaging. Inspect it for any visible damage.

- Grinder Preparation: Ensure your angle grinder is unplugged or its battery is removed before attempting to mount the wheel.

- Wheel Selection: Verify that the chosen 3M Cubitron 3 grinding wheel matches the specifications (diameter, arbor hole, maximum RPM) of your angle grinder. The model 90007 is 5 inches in diameter with a 7/8 inch arbor hole.

- Mounting: Place the grinding wheel onto the grinder's arbor, ensuring it sits flush against the inner flange. Secure it with the outer flange and tighten the locking nut using the appropriate wrench. Ensure the wheel is centered and not wobbling.

- Guard Adjustment: Adjust the grinder's safety guard to provide maximum protection while allowing for the grinding operation.

- Test Run: Before applying to a workpiece, briefly run the grinder at full speed in a safe area to ensure the wheel is properly seated and runs smoothly without excessive vibration.

Operating Instructions

Follow these guidelines for safe and effective operation of your 3M Cubitron 3 Grinding Wheel:

- Wear PPE: Always wear all recommended Personal Protective Equipment (PPE) as outlined in the Safety Information section.

- Proper Grip: Hold the angle grinder firmly with both hands.

- Starting the Grinder: Start the grinder before making contact with the workpiece. Allow the wheel to reach full operating speed.

- Grinding Angle: Maintain a shallow angle (typically 15-30 degrees) between the grinding wheel and the workpiece for optimal material removal and wheel life.

- Apply Consistent Pressure: Apply steady, moderate pressure. Avoid excessive force, as the Cubitron 3 grain is designed to cut efficiently with less pressure. Excessive pressure can lead to overheating, premature wear, and potential wheel damage.

- Controlled Movement: Move the grinder smoothly and consistently across the workpiece. Avoid dwelling in one spot, which can cause heat buildup and gouging.

- Material Compatibility: This wheel is highly effective on stainless steel, mild steel, and aerospace alloys, but can be used on almost all metals.

- Cooling: For prolonged grinding, allow the wheel and workpiece to cool periodically to prevent overheating.

- Finishing: For finer finishes, reduce pressure and use a lighter touch.

- Stopping the Grinder: Lift the grinder clear of the workpiece before turning it off. Allow the wheel to come to a complete stop before setting the tool down.

Image: A worker wearing appropriate safety gear, including a face shield and gloves, operating an angle grinder fitted with a 3M Cubitron 3 wheel. Sparks are visible as the wheel grinds metal, demonstrating the product in action.

Image: A graphic detailing the primary application of the grinding wheel as "Grinding" and its compatibility with "All metals" and "Stainless steel."

Maintenance

- Regular Inspection: Periodically inspect the grinding wheel for signs of wear, such as reduced diameter, glazing, or loading. Replace the wheel when it reaches its wear limit or shows signs of damage.

- Cleaning: Keep the grinding wheel clean and free from debris. A wire brush can be used to remove loaded material if necessary, but avoid damaging the abrasive surface.

- Storage: Store grinding wheels in a dry, cool place, away from direct sunlight and extreme temperatures. Store them flat or on a rack to prevent warping or damage.

- Handling: Handle grinding wheels carefully to avoid dropping or striking them, which can cause unseen damage.

Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Reduced Cutting Performance | Glazing (wheel surface appears smooth), Loading (metal particles embedded in wheel), Worn out wheel | Apply more pressure initially to break down grain, use a dressing stick to clean/sharpen the wheel, replace the wheel if worn beyond limits. |

| Excessive Vibration | Improperly mounted wheel, Damaged wheel, Worn grinder components | Re-mount the wheel ensuring it's centered and tight, inspect wheel for damage and replace if necessary, inspect grinder for worn bearings or arbor. |

| Rapid Wheel Wear | Excessive pressure, Incorrect grinding angle, Grinding wrong material type | Reduce pressure, maintain optimal grinding angle (15-30 degrees), ensure wheel is suitable for the material being ground. |

| Overheating of Workpiece/Wheel | Excessive pressure, Dwelling in one spot, Insufficient cooling time | Reduce pressure, keep the grinder moving across the workpiece, allow for cooling breaks during prolonged grinding. |

Product Video

Video: "Introducing 3M Cubitron 3 Performance Abrasives." This official video from 3M Industrial Market Center showcases the features and benefits of the Cubitron 3 line, including its extended life and improved cut rate, demonstrating its use in various industrial grinding applications.

Warranty and Support

For specific warranty information and technical support regarding your 3M Cubitron 3 Depressed Center Grinding Wheel, please refer to the official 3M website or contact 3M customer service directly. Product literature and safety data sheets are also available on the 3M website.

Visit the official 3M website: www.3M.com