1. Introduction

The GasDog GD300-NH3 Fixed Ammonia Detector is an advanced electronic device designed for continuous monitoring and detection of ammonia gas (NH3) concentrations in the air. It employs high-precision electrochemical sensors to accurately measure ammonia levels, providing real-time data and triggering alarms when concentrations exceed predetermined thresholds. This device is crucial for ensuring safety and environmental protection in industrial settings such as chemical plants, refrigeration systems, water treatment facilities, and agricultural operations where ammonia may be present.

This manual provides essential information for the proper installation, operation, maintenance, and troubleshooting of your GD300-NH3 detector. Please read it thoroughly before using the product.

2. Safety Information

Always adhere to the following safety guidelines to prevent injury, damage to the device, or inaccurate readings:

- Professional Installation: Installation should only be performed by qualified personnel in accordance with local electrical codes and safety regulations.

- Power Supply: Ensure the device is connected to a stable 24V power supply as specified. Incorrect voltage can damage the unit.

- Explosion-Proof Design: The GD300-NH3 features an explosion-proof design. Do not modify the device or use it in environments exceeding its specified explosion-proof grade.

- Calibration: Regular calibration is essential for accurate readings. Refer to the maintenance section for calibration procedures.

- Environmental Conditions: Operate the detector within the specified temperature and humidity ranges to ensure optimal performance.

- Alarm Response: In case of an alarm, immediately follow your facility's emergency procedures for gas leaks. Do not ignore alarms.

- Maintenance: Disconnect power before performing any maintenance or servicing.

3. Product Overview

The GasDog GD300-NH3 detector is designed for robust and reliable ammonia gas monitoring. Key features include:

- High Precision Sensor: Utilizes high-precision electrochemical sensors for accurate gas leak detection.

- Compatibility and Output: Compatible with various control systems (PLC, DCS) for remote monitoring. Equipped with 3-wire 4-20mA signal output.

- Explosion-Proof Design: Ensures fast, reliable, and stable operation in hazardous environments.

- Sound and Light Alarms: Features two levels of configurable sound and light alarms to alert personnel.

- Self-Calibration Function: Includes a self-calibration function for simplified on-site maintenance using standard keys.

- Durable Construction: Made from die-cast aluminum material, providing durability, rust-proof, and anti-corrosion properties.

3.1. Components and Views

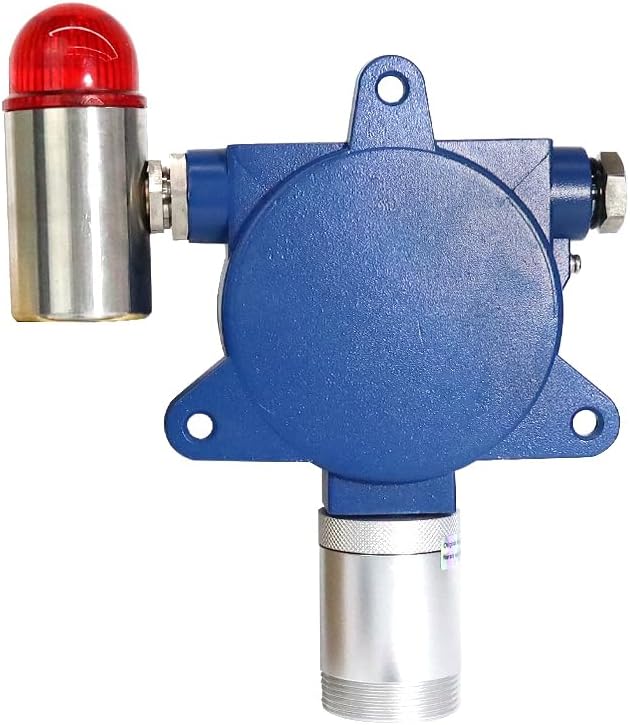

Figure 1: Front view of the GD300-NH3 detector, showing the digital display and the integrated sound and light alarm unit.

Figure 2: Rear view of the GD300-NH3 detector, highlighting the mounting holes and cable connections.

Figure 3: The GD300-NH3 detector alongside its accessories, including the user manual, remote control, and a calibration cap.

Figure 4: Detailed diagram illustrating the main components of the GD300-NH3 detector, including the display, mounting points, sensor probe, and alarm unit.

3.2. Product Video Overview

Video 1: An overview of the GasDog GD300 Fixed Gas Detector, showcasing its design and features.

Video 2: A demonstration of the GasDog GD300 gas detector, highlighting its operational aspects.

4. Setup

Proper installation is critical for the accurate and safe operation of the GD300-NH3 detector. It is highly recommended that installation be performed by a certified professional.

4.1. Mounting Location

- Choose a location where ammonia gas is most likely to accumulate. Ammonia is lighter than air, so detectors should typically be mounted near the ceiling or at a higher level.

- Avoid mounting near ventilation outlets, doors, windows, or direct heat sources that could affect readings.

- Ensure the mounting surface is stable and free from vibrations.

- Allow sufficient space around the detector for maintenance and access.

4.2. Wiring and Power Connection

- The GD300-NH3 requires a 24V DC power supply. Ensure the power source meets the specified voltage and current requirements (100mA).

- Connect the 3-wire 4-20mA signal output to your control system (PLC, DCS) as per the system's wiring diagram.

- Use appropriate explosion-proof cable glands and conduits to maintain the integrity of the explosion-proof enclosure.

- Verify all connections are secure and correctly polarized before applying power.

4.3. Initial Power-Up

- After installation and wiring are complete, apply power to the detector.

- The device will undergo a self-test and warm-up period. During this time, the display may show varying readings or diagnostic codes.

- Allow the detector to stabilize for at least 5-10 minutes before assuming normal operation.

5. Operating

Once installed and powered, the GD300-NH3 operates continuously to monitor ammonia levels.

5.1. Reading the Display

- The digital display shows the current ammonia concentration in parts per million (ppm).

- Observe the display for real-time readings.

5.2. Alarm Indications

The detector features two levels of sound and light alarms:

- Level 1 Alarm: Triggered when ammonia concentration reaches the first preset alarm point. The red light will flash, and an audible alarm will sound.

- Level 2 Alarm: Triggered when ammonia concentration reaches the second, higher preset alarm point. The red light will flash more rapidly, and the audible alarm will be more urgent.

- Alarm points can be configured during setup or maintenance using the remote control.

5.3. Remote Control Function

The included remote control allows for convenient adjustment of settings without needing to open the detector's cover. Functions typically include:

- Setting alarm points.

- Zero-point calibration.

- Address modification (for networked systems).

Refer to the remote control's specific instructions for detailed usage.

6. Maintenance

Regular maintenance ensures the longevity and accuracy of your GD300-NH3 detector.

6.1. Calibration

The GD300-NH3 has a self-calibration function. Regular calibration (e.g., every 6-12 months, or as required by local regulations) is crucial to maintain accuracy. Use certified standard gas for calibration. Follow the on-screen prompts and remote control instructions for the calibration process.

6.2. Cleaning

- Periodically clean the exterior of the detector with a soft, damp cloth.

- Do not use abrasive cleaners or solvents.

- Ensure the sensor opening is free from dust, debris, or obstructions.

6.3. Sensor Replacement

The electrochemical sensor has a limited lifespan. If the detector consistently provides inaccurate readings after calibration, or if a sensor fault is indicated, the sensor may need replacement. Contact GasDog support or a qualified technician for sensor replacement.

7. Troubleshooting

If you encounter issues with your GD300-NH3 detector, refer to the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| No power/Display off | No power supply; Incorrect wiring; Blown fuse. | Check power connections and source; Verify wiring according to diagram; Check and replace fuse if necessary. |

| Inaccurate readings | Sensor drift; Sensor contamination; Sensor nearing end of life; Interference from other gases. | Perform calibration; Clean sensor area; Consider sensor replacement; Ensure proper ventilation and isolation from interfering substances. |

| Alarm constantly active (false alarm) | High background gas level; Sensor contamination; Faulty sensor; Alarm set point too low. | Ventilate area; Clean sensor; Calibrate or replace sensor; Adjust alarm set points (if safe and appropriate). |

| Alarm not triggering | Low gas concentration; Faulty alarm unit; Alarm set point too high; Wiring issue to control system. | Verify gas presence with another device; Check alarm unit connections; Adjust alarm set points; Inspect wiring to control system. |

| No 4-20mA output | Wiring error; Internal fault. | Check output wiring to control system; Contact support for internal diagnostics. |

If the problem persists after attempting these solutions, please contact GasDog customer support.

8. Specifications

| Feature | Detail |

|---|---|

| Brand | GasDog |

| Model | GD300-NH3 |

| Measuring Range | 0-200ppm (Ammonia) |

| Sensor Type | Electrochemical |

| Output Signal | 4-20mA (3-wire) |

| Relay Output | 2NO+2NC 24V 100mA |

| Alarm Type | Audible and Visual (Sound and Light) |

| Operating Humidity | Up to 95% (non-condensing) |

| Material | Die-cast Aluminum |

| Power Source | 24V DC (Wired, not battery powered as per product title) |

9. Warranty and Support

GasDog is committed to providing high-quality products and excellent customer service.

9.1. Product Warranty

For specific warranty details, please refer to the warranty card included with your product or visit the official GasDog website. Generally, products are covered against manufacturing defects for a specified period from the date of purchase.

9.2. Customer Support

If you have any inquiries, require technical assistance, or encounter issues with your GD300-NH3 detector, please do not hesitate to contact us. Our customer service team is available to provide support and satisfactory responses.

- Email: Please refer to the contact information provided on the product packaging or the official GasDog website.

- We aim to reply to all inquiries within 12 hours.

For more information about GasDog products and services, you can visit the GasDog Store on Amazon.