1. Introduction

This manual provides essential information for the safe and effective use of your YATOINTO Aluminum Hand Chain Hoist, Model 0.25T-10FT Fixed Back Cover. This compact and lightweight manual chain hoist is designed for various lifting tasks, offering a maximum load capacity of 0.25 tons (550 lbs) and a lifting height of 10 feet. It features a robust aluminum alloy body, G80 grade manganese steel chain, and a reliable mechanical load brake system. Please read this manual thoroughly before operation to ensure proper handling, maintenance, and safety.

2. Safety Information

WARNING: Failure to follow these safety instructions may result in serious injury or death.

- Always inspect the hoist, chain, and hooks for damage or wear before each use. Do not use if any components are compromised.

- Ensure the hoist is securely attached to a structure capable of supporting the maximum rated load plus the weight of the hoist itself.

- Never exceed the rated load capacity of 0.25 tons (550 lbs). Overloading can cause structural failure and severe injury.

- Keep hands and body clear of the load and chain during operation.

- Do not use the hoist to lift people or loads over people.

- Ensure the load is balanced and properly secured before lifting.

- Avoid sudden jerking or swinging of the load. Operate the hoist smoothly.

- Do not leave a suspended load unattended.

- Only trained and authorized personnel should operate this equipment.

- Store the hoist in a dry, clean place when not in use to prevent corrosion and damage.

3. Product Components

The YATOINTO Aluminum Hand Chain Hoist consists of several key components designed for efficient and safe lifting.

Figure 3.1: Overall view of the YATOINTO Aluminum Hand Chain Hoist, showing the main unit, chains, hooks, and a compact carrying bag.

Figure 3.2: Illustration highlighting the 360° full rotation capability of the upper hook and the safety latch on the lower hook, designed to prevent accidental disengagement of the load.

Figure 3.3: Internal view of the hoist's gear combination, illustrating the multi-gear connection designed for effort-saving operation.

Figure 3.4: Detailed view of the double spine brake system, which provides enhanced safety compared to a single ratchet brake.

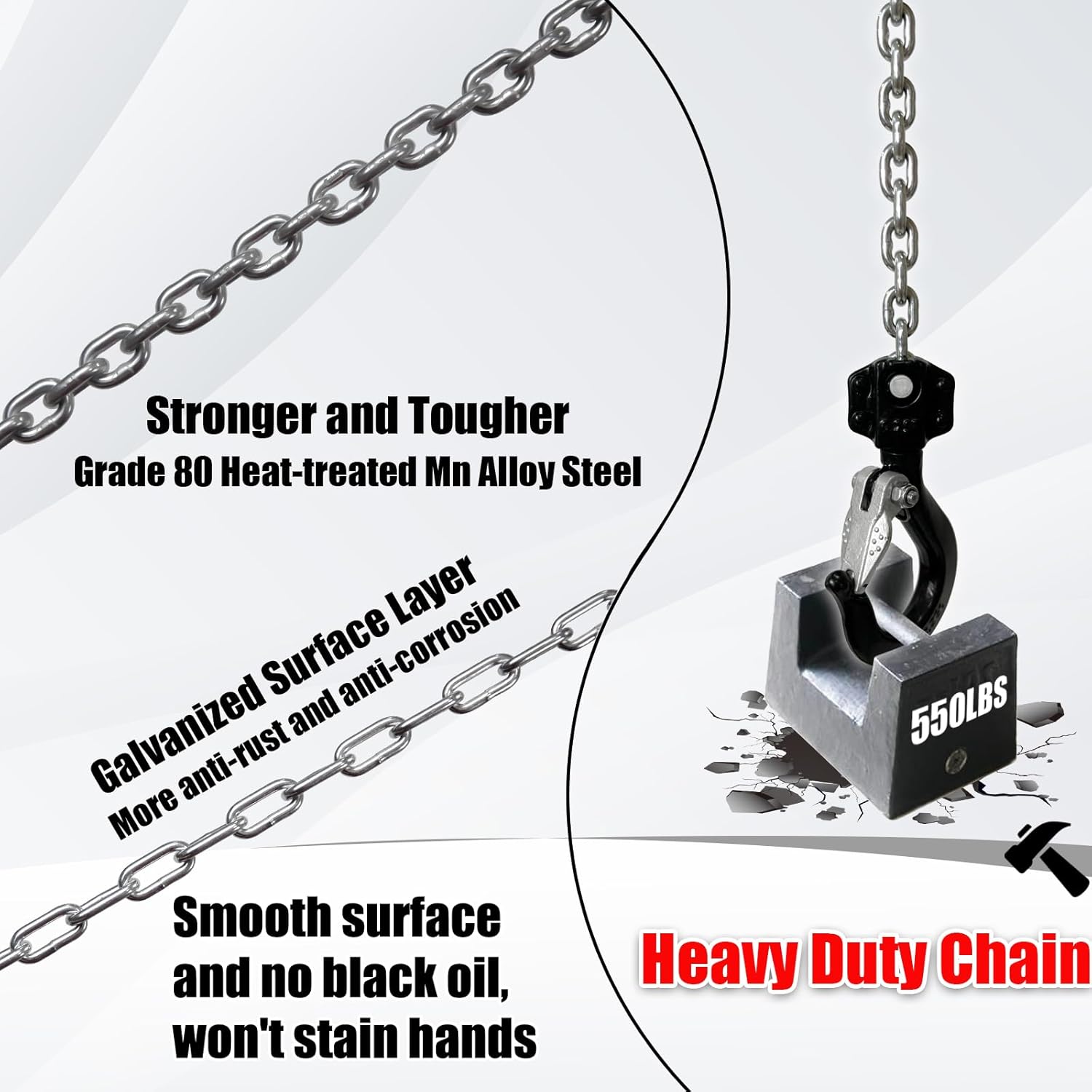

Figure 3.5: Close-up of the G80 grade heat-treated manganese alloy steel chain, featuring a galvanized surface layer for anti-rust and anti-corrosion properties, ensuring durability and smooth operation.

- Upper Hook: For attaching the hoist to a support structure. Features 360° rotation and a safety latch.

- Hoist Body: Contains the internal mechanisms, including gears and the braking system. Made of lightweight aluminum alloy.

- Hand Chain: Used to operate the lifting mechanism. Pulling this chain raises or lowers the load.

- Load Chain: The chain that supports the load. Made of G80 manganese steel for high strength.

- Lower Hook: For attaching to the load. Equipped with a safety latch.

- Braking System: A mechanical load brake ensures the load is held securely at any position and meets ANSI/ASME B30.16 requirements.

4. Specifications

Key technical specifications for the YATOINTO Aluminum Hand Chain Hoist:

| Feature | Specification |

|---|---|

| Model | 0.25T-10FT Fixed Back Cover |

| Rated Load Capacity | 0.25 Tons (550 Lbs) |

| Standard Lifting Height | 10 Feet |

| Chain Grade | G80 Manganese Steel |

| Body Material | Aluminum Alloy |

| Brake Type | Mechanical Load Brake (Double Spine Brake) |

| Safety Standard Compliance | ANSI/ASME B30.16 |

| Full Load Hand Force | 210N |

| Test Load | 0.375 Tons (825 Lbs) |

| Approximate Weight | 6.68 Pounds |

| Dimensions (Package) | 8.46 x 5.47 x 5.04 inches |

Figure 4.1: Technical drawing illustrating the key dimensions and specifications of the YATOINTO Chain Hoist.

5. Setup & Installation

Proper setup is crucial for safe operation. Follow these steps for installation:

- Choose a Secure Anchor Point: Select an overhead support structure (e.g., I-beam, sturdy truss, or dedicated hoist mount) that is certified to safely support at least the maximum rated load of the hoist plus the weight of the hoist itself.

- Attach the Upper Hook: Open the safety latch on the upper hook and securely attach it to the chosen anchor point. Ensure the latch closes completely and the hook is seated properly. The 360° rotation allows for flexible positioning.

- Inspect the Hoist: Before first use, and before each subsequent use, perform a thorough visual inspection of the entire hoist. Check the load chain for kinks, twists, damage, or excessive wear. Verify that both the upper and lower hooks are free from deformation and that their safety latches operate correctly. Ensure the hand chain moves freely.

- Clear the Area: Ensure the area below and around the hoist is clear of personnel and obstructions before lifting any load.

6. Operating Instructions

Operating the YATOINTO Hand Chain Hoist is straightforward, but requires attention to safety and proper technique.

- Attach the Load: Open the safety latch on the lower hook and securely attach it to the load. Ensure the load is balanced and the hook is properly seated. Close the safety latch.

- Lifting the Load: To lift the load, pull the hand chain downwards. The hoist's internal gears will engage, and the load chain will retract, raising the load. Pull steadily and smoothly.

- Lowering the Load: To lower the load, pull the other side of the hand chain (or the side that causes the load to descend). The mechanical brake will control the descent, allowing for smooth and precise lowering. Maintain control of the hand chain at all times.

- Stopping the Load: Release the hand chain to stop the load at any desired height. The mechanical brake will automatically engage to hold the load securely.

- After Lifting: Once the load is safely placed and supported, release the tension on the hoist and detach the lower hook from the load.

Figure 6.1: The hoist is designed for effortless one-handed operation, allowing for smooth and controlled lifting.

7. Maintenance

Regular maintenance ensures the longevity and safe operation of your hoist.

- Regular Inspection: Conduct daily or pre-use inspections as described in the safety section. Pay close attention to the load chain, hooks, and the overall housing for any signs of damage, wear, or corrosion.

- Cleaning: Keep the hoist clean and free from dirt, debris, and excessive grease. A clean hoist operates more smoothly and allows for easier inspection.

- Lubrication: Periodically lubricate the load chain and internal moving parts as recommended by the manufacturer (though specific lubrication points are not detailed in the provided data, general hoist maintenance includes this). Use a high-quality lubricant suitable for chains and gears.

- Storage: When not in use, store the hoist in a dry, clean environment to prevent rust and damage. The provided carrying bag is ideal for protection.

- Professional Servicing: For any significant repairs or if you suspect internal damage, consult a qualified professional or the manufacturer. Do not attempt complex repairs yourself unless you are certified.

8. Troubleshooting

This section addresses common issues you might encounter with your hand chain hoist.

| Problem | Possible Cause | Solution |

|---|---|---|

| Hoist not lifting/lowering smoothly | Kinked or twisted load chain; insufficient lubrication; internal mechanism obstruction. | Check and untwist the load chain. Apply appropriate lubricant to the chain and inspect for foreign objects. If issue persists, professional inspection may be needed. |

| Load slips or does not hold | Brake mechanism wear or malfunction; overloading. | Immediately lower the load safely. Do not use the hoist. This indicates a serious safety issue with the brake. Contact manufacturer or qualified service personnel. Ensure you are not exceeding the rated capacity. |

| Hand chain is difficult to pull | Overloading; lack of lubrication; internal friction. | Verify the load does not exceed the rated capacity. Lubricate the hand chain and internal components. If resistance continues, inspect for internal damage or wear. |

| Hooks or chain appear damaged | Wear and tear; improper use; overloading. | Do not use the hoist. Damaged hooks or chains are a severe safety hazard. Replace damaged components with genuine manufacturer parts or consult a professional for repair. |

If you encounter problems not listed here or if solutions do not resolve the issue, discontinue use immediately and contact YATOINTO customer support or a certified service technician.

9. Applications

The YATOINTO Aluminum Hand Chain Hoist is versatile and suitable for a wide range of lifting tasks in various environments due to its compact size, lightweight design, and robust construction.

- Factories: For lifting components, machinery, or materials within production lines or assembly areas.

- Garages & Workshops: Ideal for engine removal, vehicle maintenance, or lifting heavy tools and equipment.

- Warehouses: Assisting with loading, unloading, and repositioning goods.

- Farms: Useful for lifting agricultural equipment, feed bags, or other heavy items.

- Shipbuilding: For handling parts and equipment during construction or repair.

- Transportation: A portable solution for roadside assistance, loading/unloading from trucks, or securing cargo.

- Construction Sites: For lifting building materials, tools, or small machinery in areas without power access.

- Mines: Suitable for specific lifting needs in mining operations where manual control is preferred.

Figure 9.1: Visual representation of the diverse applications where the YATOINTO Hand Chain Hoist can be effectively utilized.

10. Warranty & Support

YATOINTO is committed to providing high-quality products. For information regarding product warranty, technical support, or service, please refer to the contact information provided with your purchase or visit the official YATOINTO website. Always use genuine YATOINTO replacement parts for any repairs to ensure continued safety and performance.

Contact Information: Please refer to the packaging or the official YATOINTO website for the most current customer service contact details.