1. Introduction

This manual provides essential instructions for the safe and efficient operation, setup, and maintenance of your Longer LK5 Pro 3D Printer. It covers the main printer unit, the upgraded dual blower kit, the filament breakage detection sensor, and the included copper nozzles. Please read this manual thoroughly before using the printer to ensure optimal performance and longevity.

Figure 1.1: Longer LK5 Pro 3D Printer with accessories. This image displays the complete package, including the main printer unit, the filament breakage detection sensor kit (visible on the right, consisting of two small circuit boards and a blue-tipped housing), and a set of five copper nozzles (bottom right).

2. Safety Instructions

- Always operate the printer in a well-ventilated area.

- Keep the printer away from flammable materials and heat sources.

- Do not touch the hot nozzle or heated bed during operation. Allow components to cool before handling.

- Ensure the power supply is correctly connected and grounded.

- Keep children and pets away from the printer during operation.

- Do not attempt to modify the printer's electrical components.

- Unplug the printer from the power outlet before performing any maintenance or cleaning.

3. Setup

3.1 Unpacking and Initial Assembly

The Longer LK5 Pro 3D Printer arrives 90% pre-assembled, significantly reducing setup time. Modular design allows for assembly within approximately 15 minutes.

Figure 3.1: 90% Pre-assembled Printer. The image highlights the modular components, indicating the minimal steps required to complete the assembly. Key components are numbered for easy identification during the assembly process.

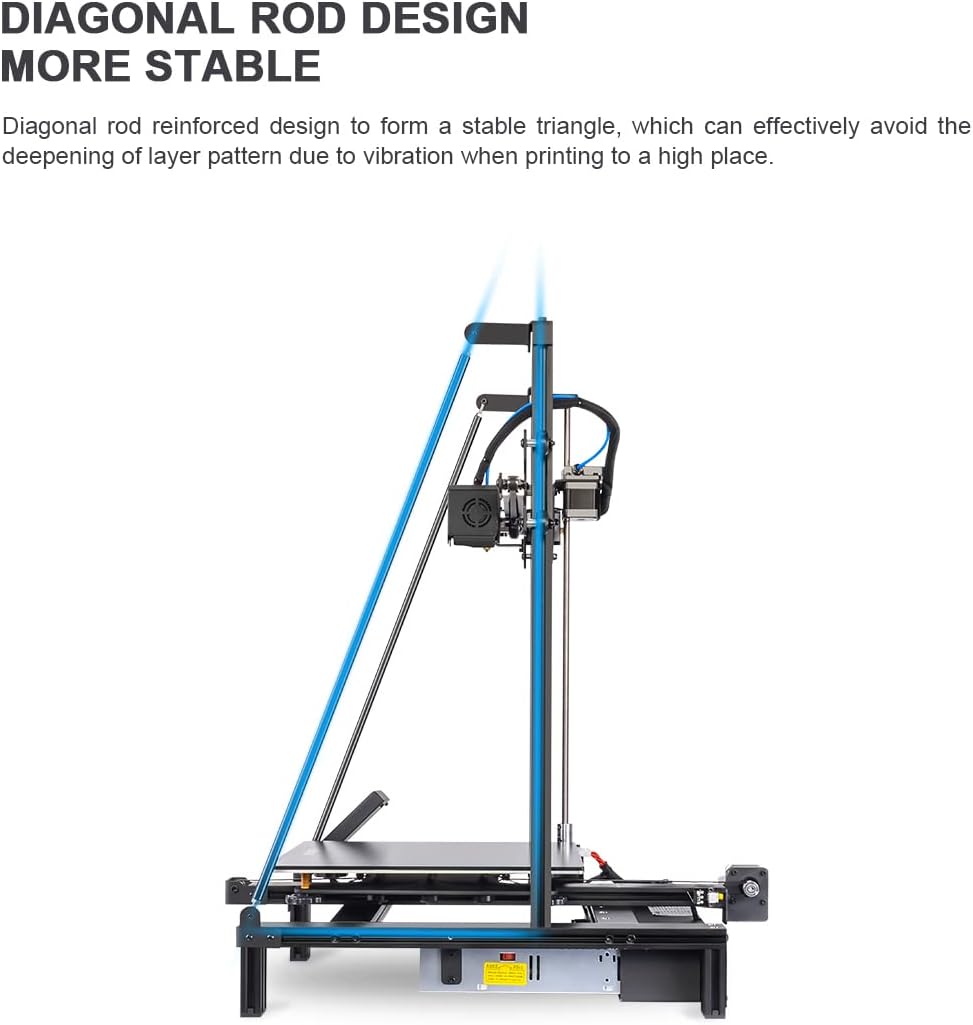

3.2 Structural Stability: Diagonal Rod Design

The printer features a diagonal rod reinforced design, forming a stable triangular structure. This design effectively minimizes vibration during printing, especially at higher print heights, preventing the deepening of layer patterns and ensuring print quality.

Figure 3.2: Diagonal Rod Design. This diagram visually represents the reinforced diagonal rods that contribute to the printer's overall stability, crucial for precise printing.

3.3 Print Platform: Lattice Glass

The Longer LK5 Pro utilizes a removable lattice glass platform, offering several advantages for 3D printing:

- Easy to take off: Prints adhere well during printing but are easy to remove once cooled.

- Durable: Resistant to wear and tear.

- Strong adhesion: Provides excellent first-layer adhesion.

- High temperature resistant: Can withstand the necessary printing temperatures.

- No warping: Maintains flatness over time, ensuring consistent print quality.

Figure 3.3: Lattice Glass Platform. This image provides a detailed view of the print surface, emphasizing its texture and the 'LONGER' branding, along with icons representing its key benefits.

3.4 Dual Blower Kit Installation

The upgraded dual blower kit provides enhanced cooling for printed models, which is crucial for bridging, overhangs, and overall print quality. Ensure the blowers are securely mounted and connected according to the provided wiring diagram (refer to separate installation guide if included).

Figure 3.4: Enhanced Cooling System. This image focuses on the dual blower setup, visually representing the airflow for efficient cooling of the printed object.

3.5 Filament Breakage Detection Sensor Installation

The filament breakage detection sensor monitors the filament path. If the filament runs out or breaks, the printer will automatically pause, preventing failed prints and saving material. Install the sensor in the designated location on the printer's frame, ensuring the filament passes through it correctly.

4. Operating Instructions

4.1 Loading Filament

- Heat the nozzle to the appropriate temperature for your filament type.

- Insert the filament into the filament detection sensor, then guide it through the extruder mechanism.

- Manually feed the filament until it extrudes smoothly from the nozzle.

4.2 Starting a Print

- Prepare your 3D model using a compatible slicing software (e.g., Cura, PrusaSlicer). The LK5 Pro is an open-source printer, allowing flexibility with software.

- Save the sliced G-code file to an SD card.

- Insert the SD card into the printer's card slot.

- Select the desired file from the printer's touchscreen interface to begin printing.

4.3 Resume Printing Function

The LK5 Pro features a power failure recovery function. In the event of a power outage or accidental disconnection, the printer can resume printing from where it left off once power is restored. This feature, combined with the filament detector, increases the success rate of long prints.

Figure 4.1: Built-in Filament Detector and Resume Printing. This image illustrates the printer's capability to monitor filament status and recover from power interruptions, indicated by the respective icons on the display.

4.4 Large Print Volume

The Longer LK5 Pro offers a generous print size of 11.8" x 11.8" x 15.7" (300 x 300 x 400mm), allowing for the creation of large-scale models or multiple smaller objects in a single print job.

Figure 4.2: Large Print Size Capability. This image showcases the printer's ability to produce substantial objects, exemplified by the large engine block model being printed on its bed.

5. Maintenance

5.1 Cleaning the Print Platform

After each print, allow the lattice glass platform to cool. Once cool, prints should detach easily. Clean the surface with isopropyl alcohol to remove any residue and ensure optimal adhesion for subsequent prints.

5.2 Nozzle Replacement

Over time, nozzles can wear out or become clogged. The Longer LK5 Pro uses standard 0.4mm copper nozzles. To replace:

- Heat the hotend to the filament's printing temperature.

- Carefully unscrew the old nozzle using a wrench while holding the heater block steady.

- Screw in the new copper nozzle, ensuring it is tightened securely but not overtightened.

- Perform a test print to verify proper extrusion.

Figure 5.1: Copper Nozzles. This image displays a set of five 0.4mm copper nozzles, which are standard replacement parts for the Longer LK5 Pro 3D Printer.

5.3 Lubrication

Periodically lubricate the Z-axis lead screws and smooth rods with a small amount of lithium grease or specialized 3D printer lubricant to ensure smooth movement and prevent wear.

6. Troubleshooting

- Print not sticking to bed: Ensure the bed is level, clean, and heated to the correct temperature. Adjust Z-offset if necessary.

- Filament not extruding: Check for clogged nozzle (perform cold pull or replace nozzle), ensure filament is loaded correctly, and verify hotend temperature.

- Layer shifting: Check belt tension, ensure all axes move freely, and verify print speed settings. The diagonal rod design helps mitigate this issue.

- Filament detection sensor error: Ensure filament is properly inserted through the sensor. Check sensor wiring for loose connections.

- Poor print quality (stringing, blobs): Adjust retraction settings, print temperature, and cooling fan speed (utilize the dual blower kit's capabilities).

7. Specifications

| Feature | Specification |

|---|---|

| Brand | Longer |

| Model | LK5 Pro |

| Print Size (L×W×H) | 300 x 300 x 400 mm (11.8" x 11.8" x 15.7") |

| Print Technology | FDM (Fused Deposition Modeling) |

| Nozzle Diameter | 0.4 mm (standard) |

| Print Platform | Lattice Glass |

| Filament Compatibility | PLA, ABS, PETG, TPU, etc. |

| Operating System | Linux (internal system) |

| Connectivity | SD Card |

| Special Features | Dual Blower Kit, Filament Breakage Detection, Resume Printing, Open Source, Diagonal Rod Design |

8. Warranty and Support

For warranty information and technical support, please refer to the official Longer website or contact your retailer. Keep your purchase receipt as proof of purchase. Support resources often include FAQs, troubleshooting guides, and contact details for direct assistance.