1. Product Overview

The VEVOR 4 Quart Single Acting Hydraulic Pump is a robust power unit designed for various lifting and stamping applications. It features a 12V DC motor, a 4-quart reservoir, and delivers a high flow rate for efficient operation.

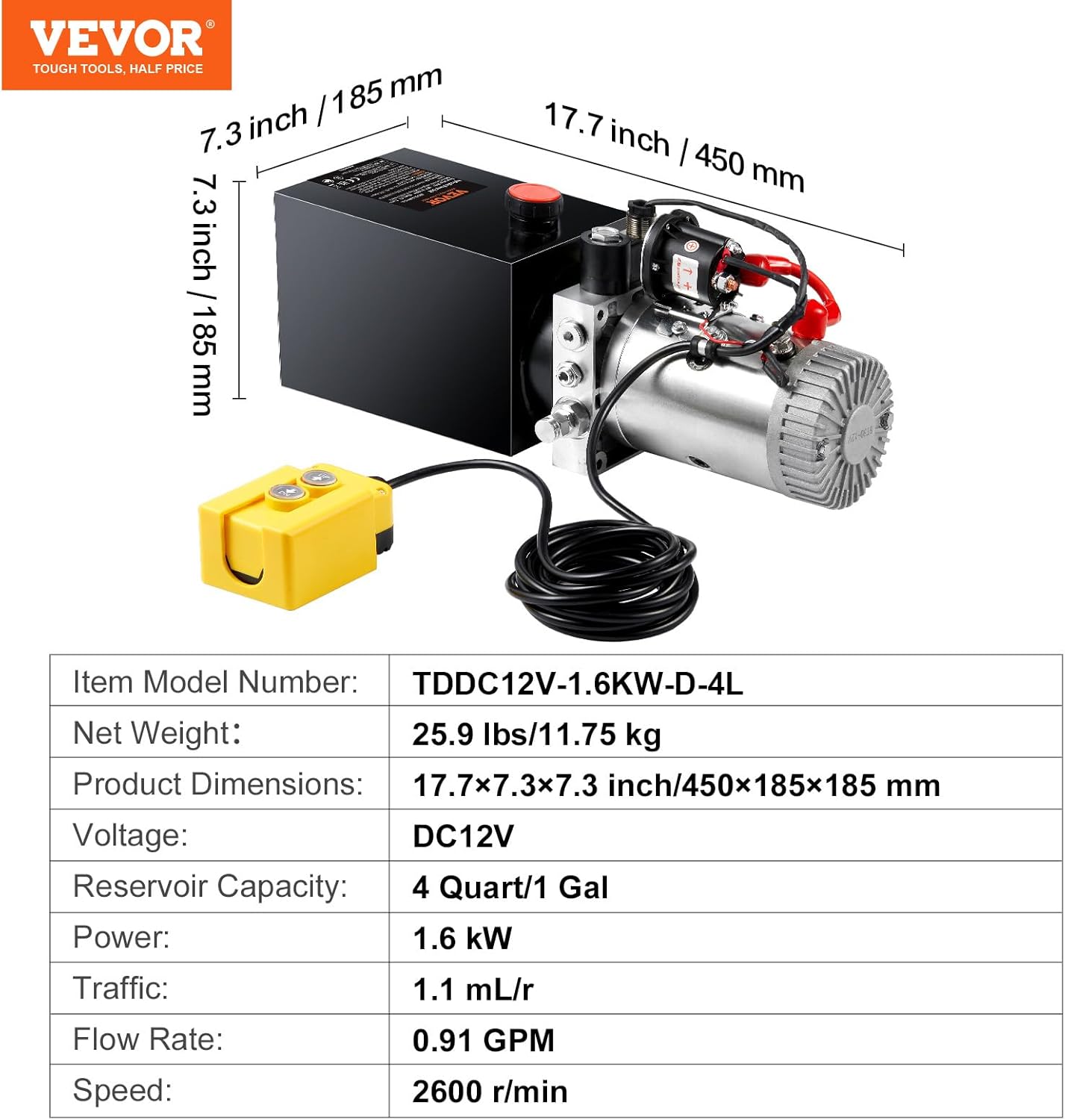

Image 1.1: VEVOR 4 Quart Single Acting Hydraulic Pump with remote control.

Key Features:

- High-Powered Performance: Equipped with a 12V, 1.6kW DC motor, providing a flow rate of up to 0.91 GPM and a maximum relief pressure of 3200 PSI.

- Quick Lifting: Single-acting power mechanism ensures stable and reliable lifting. Includes a built-in safety relief valve to prevent over-pressure.

- Hassle-free Setup: Arrives pre-assembled for easy installation. Compatible with both metric and American interfaces via an included SAE#6 connector.

- Durable Construction: Features robust overall sealing to minimize oil leaks and a rust-proof solid metal steel tank for long-lasting durability.

- Versatile Applications: Suitable for dump trailers, container truck tailgates, hydraulic wood splitters, small presses, lifting platforms, semi-electric push trucks, bucket transporters, and more.

Image 1.2: Common applications for the VEVOR Hydraulic Pump.

2. Specifications

Detailed technical specifications for the VEVOR 4 Quart Single Acting Hydraulic Pump.

Image 2.1: Product dimensions and key specifications.

| Specification | Value |

|---|---|

| Item Model Number | TDDC12V-1.6KW-D-4L |

| Net Weight | 25.8 pounds (11.75 kg) |

| Product Dimensions | 17.7 x 7.3 x 7.3 inches (450 x 185 x 185 mm) |

| Voltage | 12 Volts DC |

| Wattage | 3 KW |

| Reservoir Capacity | 4 Quart / 1 Gallon |

| Flow Rate | 0.91 Gallons Per Minute (GPM) |

| Max Relief Pressure | 3200 PSI (16-20 MPa) |

| Style | Single Acting |

| Included Components | Hydraulic Pump, SAE#6 Converter |

3. Setup Instructions

Follow these steps to properly set up your VEVOR Hydraulic Pump. Ensure all connections are secure before operation.

Image 3.1: Visual guide for connecting and operating the hydraulic pump.

- Add Hydraulic Oil: Remove the oil filler cap. Fill the reservoir with anti-wear hydraulic oil, ensuring a kinematic viscosity of 22-46mm²/s at 50°C. Do not overfill.

- Connect Hydraulic Hoses: Connect the appropriate hydraulic hoses from your equipment to the pump's hydraulic ports. Ensure all fittings are tightened securely to prevent leaks. The pump includes an SAE#6 connector for compatibility.

- Connect Power Supply: Connect the pump to a DC 12V, 200A power supply (e.g., a battery). Ensure correct polarity: connect the positive (+) terminal of the pump to the positive terminal of the battery, and the negative (-) terminal of the pump to the negative terminal of the battery. Refer to the connection label on the pump.

- Secure Mounting: Mount the hydraulic pump securely to a stable surface, ensuring it is protected from excessive vibration and environmental elements.

Video 3.1: This video demonstrates the general setup and operation of a VEVOR hydraulic pump. Please note that while the principles are similar, this video may show a double-acting model, whereas your product is a single-acting unit. Pay close attention to oil filling, hose connections, and electrical wiring.

4. Operating Instructions

Once the hydraulic pump is properly installed and connected, you can begin operation using the remote control.

Image 4.1: Illustration of single-acting lift operation (fast lifting and gravity lowering).

- Power On: Ensure the power supply is active and the pump is ready for operation.

- Lifting (Upward Movement): Press and hold the "UP" button on the remote control. The pump will activate, and hydraulic fluid will be pushed to extend the cylinder, causing the equipment to lift. Release the button to stop lifting.

- Lowering (Downward Movement): Press and hold the "DOWN" button on the remote control. For single-acting systems, this typically releases pressure, allowing the equipment to lower under gravity. Release the button to stop lowering.

- Monitor Operation: Observe the equipment during operation to ensure smooth and controlled movement. If any unusual noises or movements occur, release the button immediately and investigate.

The remote control provides extended wiring for distant operation and monitoring, enhancing safety and convenience.

5. Maintenance

Regular maintenance ensures the longevity and optimal performance of your hydraulic pump.

- Check Hydraulic Fluid Level: Periodically inspect the hydraulic fluid level in the reservoir. Refill as necessary with the recommended anti-wear hydraulic oil.

- Inspect for Leaks: Regularly check all hydraulic connections, hoses, and seals for any signs of leaks. Address any leaks promptly to prevent fluid loss and system damage.

- Clean the Pump: Keep the exterior of the pump clean and free from dirt, dust, and debris. This helps prevent contamination and ensures proper heat dissipation.

- Check Electrical Connections: Ensure all electrical connections are tight and free from corrosion. Loose connections can lead to intermittent operation or damage.

- Filter Replacement: If your system includes a hydraulic filter, follow the manufacturer's recommendations for inspection and replacement to maintain fluid cleanliness.

6. Troubleshooting

This section provides solutions to common issues you might encounter with your hydraulic pump.

| Problem | Possible Cause | Solution |

|---|---|---|

| Pump does not operate | No power supply, loose electrical connections, faulty remote control. | Check battery connections and charge. Ensure all wiring is secure. Test remote control functionality. |

| Slow or weak lifting | Low hydraulic fluid level, air in the system, clogged filter, worn pump components. | Check and refill hydraulic fluid. Bleed air from the system. Inspect and replace filter. Contact support if pump components are suspected. |

| Hydraulic fluid leaks | Loose fittings, damaged hoses or seals. | Tighten all hydraulic fittings. Inspect hoses and seals for damage and replace if necessary. |

| Excessive noise during operation | Low fluid level, air in the system, cavitation, worn bearings. | Check fluid level and refill. Bleed air from the system. Ensure proper fluid viscosity. Contact support for internal component issues. |

7. Warranty and Support

For warranty information, technical support, or service inquiries regarding your VEVOR Hydraulic Pump, please refer to the documentation included with your purchase or visit the official VEVOR website. Ensure you have your product model number (TDDC12V-1.6KW-D-4L) and purchase details available when contacting support.

You can also visit the VEVOR Store on Amazon for more product information and support resources.