Introduction

This manual provides detailed instructions for the safe and effective use of the Flyrivergo Steel Strapping Tensioner YZM-43. Please read this manual thoroughly before operating the tool to ensure proper function and to prevent injury or damage.

Product Overview

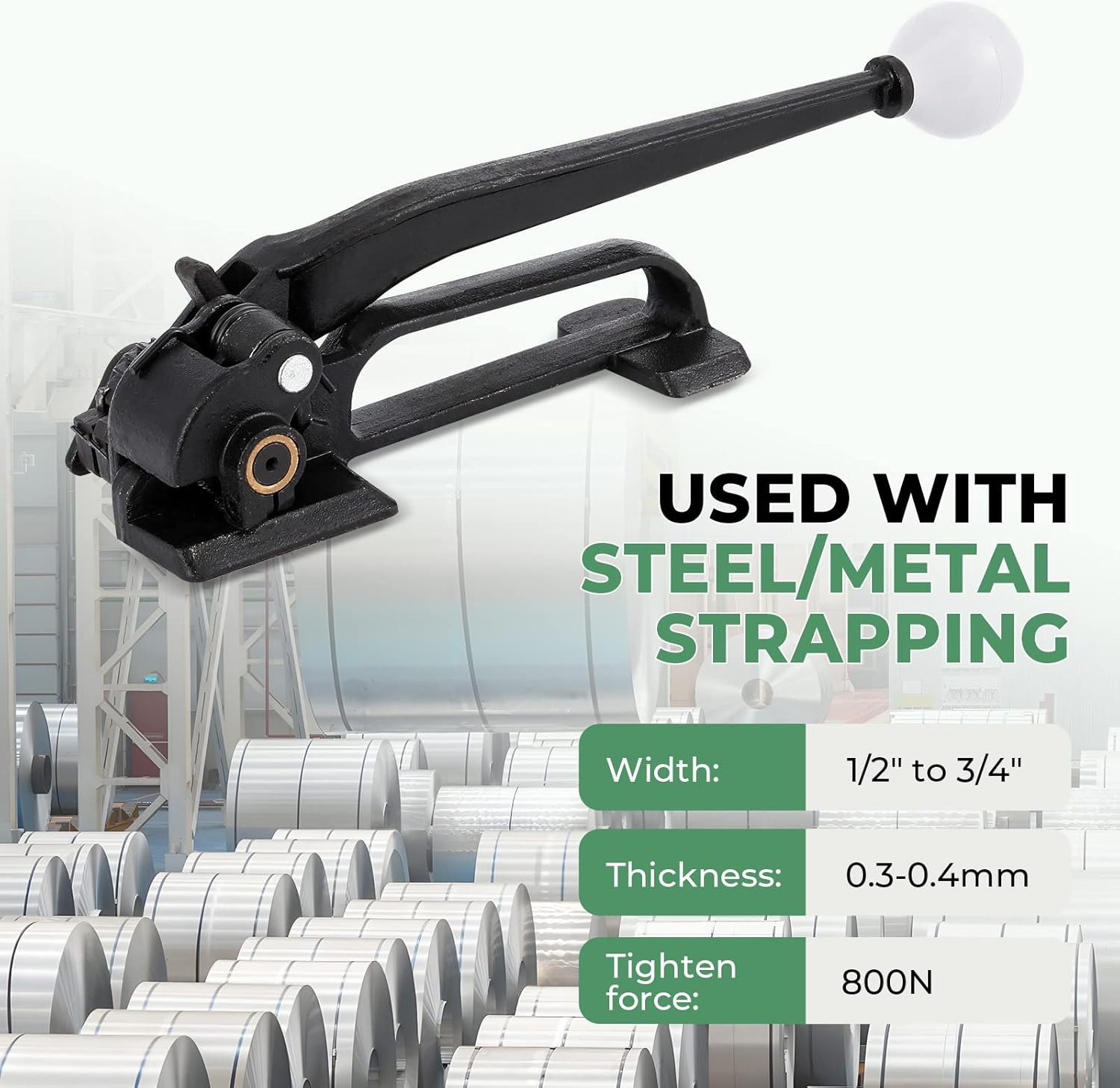

The Flyrivergo Steel Strapping Tensioner YZM-43 is a heavy-duty manual tool designed for tightening steel or metal strapping. It is suitable for strapping widths from 1/2 inch to 3/4 inch and thicknesses from 0.3mm to 0.4mm. The tool features an extended handle for efficient leverage and robust steel components for durability and high tightening force.

Image: The Flyrivergo Steel Strapping Tensioner, highlighting its compatibility with 1/2" to 3/4" width, 0.3-0.4mm thickness, and 800N tightening force.

Key Features:

- Compatibility: Designed for steel/metal strapping with widths of 1/2" to 3/4" and thicknesses of 0.3-0.4mm.

- High Tightening Force: Achieves up to 800N tightening force for secure strapping.

- Ergonomic Design: Extended handle utilizes leverage for reduced effort during operation.

- Durable Construction: Features upgraded steel components for enhanced durability and reliability.

- Versatile Application: Ideal for heavy-duty packages including steel bars, bricks, large wooden boxes, glass, wire, and carton packing.

Image: A detailed view emphasizing the heavy-duty and solid construction of the tensioner's components.

Image: Illustrative examples of heavy-duty items like steel bars and pipes, demonstrating the tool's application for securing large packages.

Setup

The Flyrivergo Steel Strapping Tensioner YZM-43 is a manual tool and requires minimal setup. Ensure the tool is clean and free from debris before use.

- Inspect the Tool: Before each use, visually inspect the tensioner for any signs of damage, wear, or loose components. Ensure all moving parts operate smoothly.

- Prepare Strapping: Select steel or metal strapping that matches the tool's specifications (1/2" to 3/4" width, 0.3-0.4mm thickness).

- Position Strapping: Place the strapping around the package or item to be secured, ensuring it is correctly aligned and ready for tensioning.

Operating Instructions

Follow these steps to effectively tension steel strapping using the Flyrivergo YZM-43 tool:

- Insert Strapping:

Press the handle of the tensioner down. This action will lift the entire feed wheel mechanism, creating space to insert the steel strapping. Slide the strapping into the tensioner, ensuring it passes through the feed wheel and gripper.

Image: Step-by-step illustration of pressing the handle (1) to lift the mechanism (2) for strapping insertion.

- Engage Feed Wheel: Release the handle. The feed wheel mechanism will lower, gripping the strapping.

- Tighten Strapping:

Shake the handle back and forth in a pumping motion. This action engages the feed wheel, pulling the strapping through the tool and applying tension. Continue until the desired tension is achieved. The extended handle design helps reduce the effort required.

Image: Visual guide on pressing the handle to insert strapping and shaking it to tighten, emphasizing reduced effort.

- Seal Strapping: Once tensioned, use a separate strapping sealer and seals (not included) to secure the strapping.

- Cut Strapping: After sealing, use a strapping cutter (not included) to cut the excess strapping.

Note: Always wear appropriate personal protective equipment, such as gloves and safety glasses, when operating strapping tools.

Maintenance

Regular maintenance ensures the longevity and optimal performance of your Flyrivergo Steel Strapping Tensioner YZM-43.

- Cleaning: After each use, clean the tool to remove any dust, dirt, or strapping residue. Use a dry cloth or a soft brush. Avoid using harsh chemicals that may damage the finish or components.

- Lubrication: Periodically apply a light machine oil to the moving parts, such as the feed wheel mechanism and handle pivot points, to ensure smooth operation. Do not over-lubricate.

- Inspection: Regularly inspect the feed wheel and gripper for wear. Worn components can reduce tensioning efficiency. Replace parts as necessary.

- Storage: Store the tensioner in a dry, clean environment to prevent rust and corrosion.

Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Strapping slips or does not tension | Worn feed wheel or gripper; incorrect strapping size; debris in mechanism. | Clean the mechanism; inspect and replace worn parts; ensure correct strapping width and thickness. |

| Handle is stiff or difficult to operate | Lack of lubrication; rust or dirt buildup. | Clean and lubricate all moving parts. |

| Strapping breaks during tensioning | Excessive tension applied; damaged strapping; strapping not aligned correctly. | Reduce tensioning force; inspect strapping for defects; ensure strapping is properly aligned. |

Specifications

| Feature | Detail |

|---|---|

| Model | YZM-43 |

| Brand | Flyrivergo |

| Compatible Strapping Width | 1/2" to 3/4" (12.7mm to 19.05mm) |

| Compatible Strapping Thickness | 0.3mm to 0.4mm |

| Tightening Force | Up to 800N |

| Material | Metal (Steel components) |

| Package Dimensions | 39.8 x 11.4 x 10.9 cm |

| Weight | 2.36 kg |

Warranty and Support

Flyrivergo provides a one-year warranty for the Steel Strapping Tensioner YZM-43. For any product-related issues or technical assistance, please contact Flyrivergo customer support. Online guidance is available.

For warranty claims or support, please refer to the contact information provided with your purchase or visit the official Flyrivergo website.