1. Product Overview

Laguna Rod's BOD WC823 is a versatile gray clay designed for pottery and modeling. It features a medium coarse texture and is formulated for firing at Cone 10. This clay offers distinct firing characteristics under different atmospheric conditions.

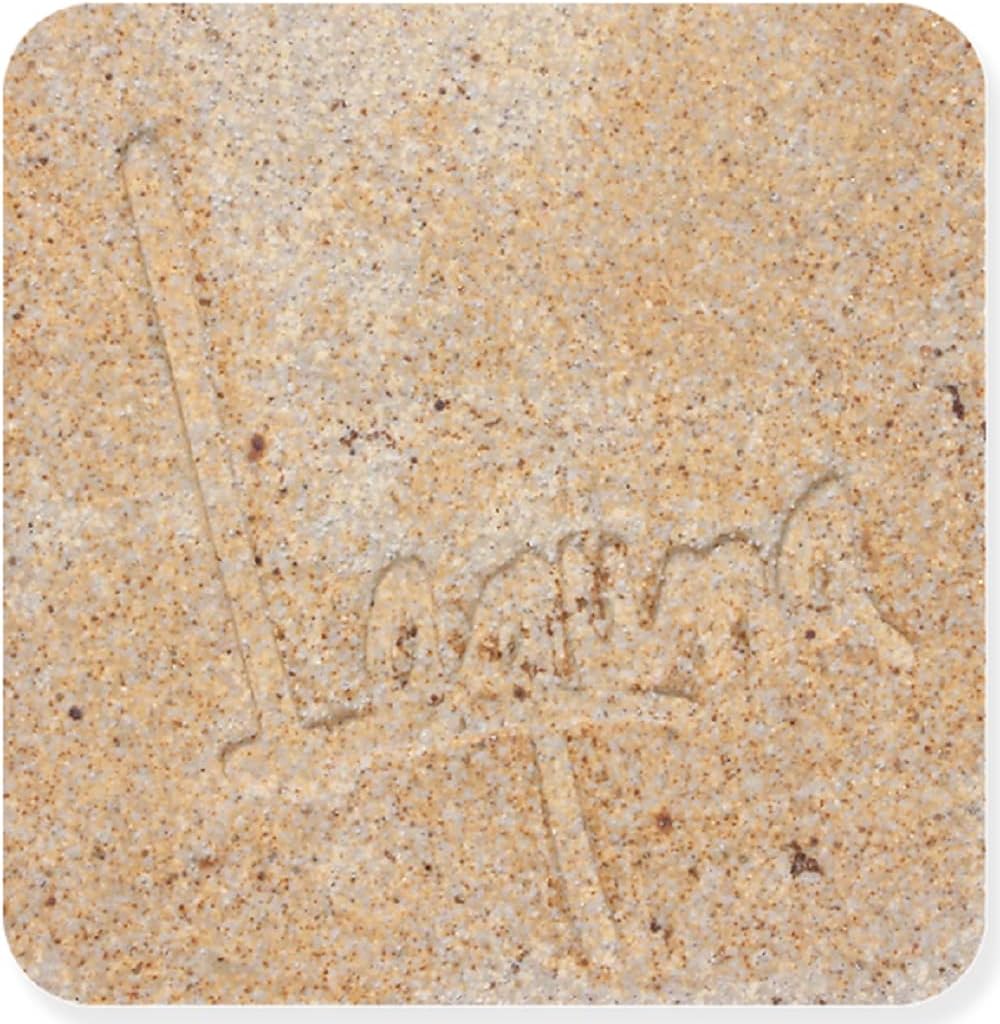

- Wet Color: Light Gray

- Firing Color (Oxidation): Yellow/Buff

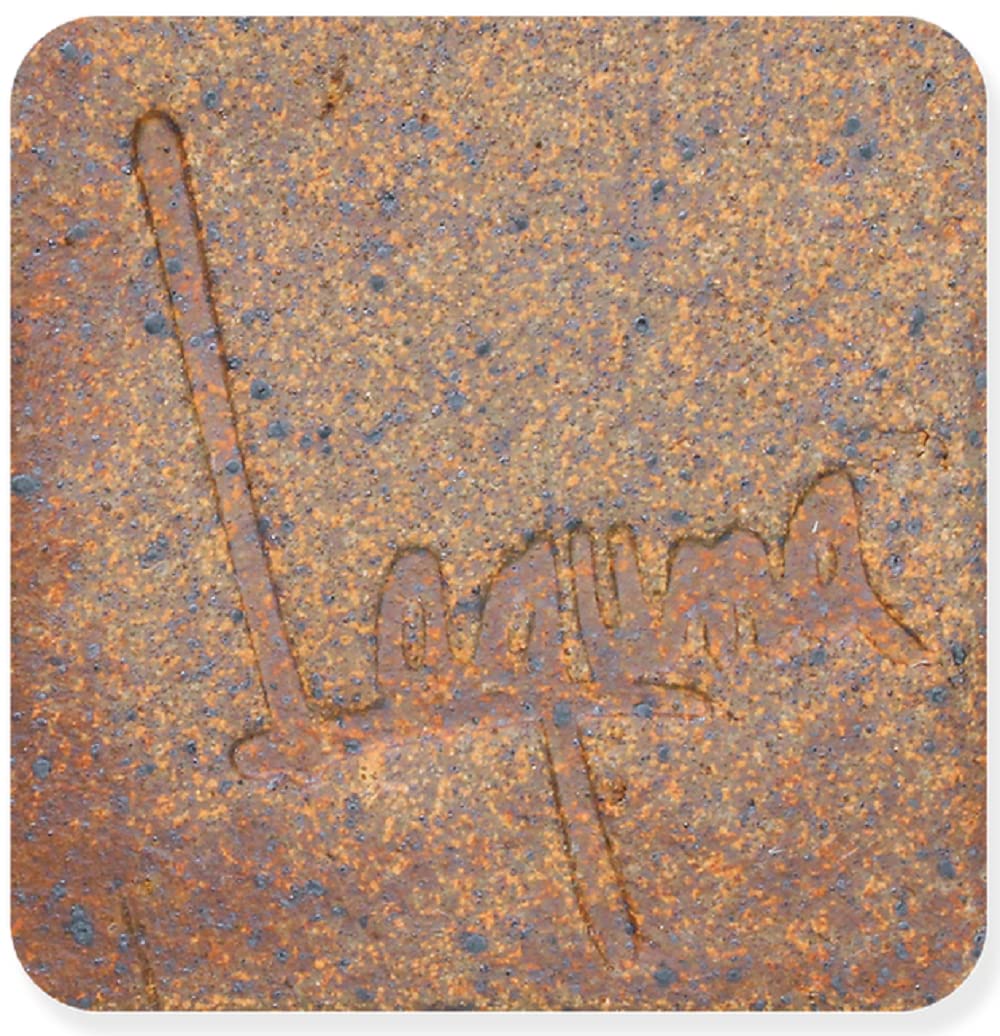

- Firing Color (Reduction): Medium Brown with iron specks that may bleed into glazes.

- Texture: Medium Coarse

- Average Shrinkage (±2%): 13.5%

This clay is a popular choice for general purpose use. However, it is important to note that large and thick-walled pieces may be prone to cracking during the drying and firing processes.

Image 1.1: Fired clay sample, demonstrating the medium brown color and iron specks achieved under reduction firing conditions.

2. Setup and Preparation

Upon receiving your Laguna Rod's BOD WC823 clay, ensure the packaging is intact. The clay is typically supplied in a moist, ready-to-use state.

- Unpacking: Carefully remove the clay from its plastic packaging.

- Wedging: Before use, it is recommended to wedge the clay thoroughly. Wedging removes air bubbles and homogenizes the clay's consistency, making it easier to work with and reducing the risk of cracking during drying and firing.

- Work Surface: Prepare a clean, stable work surface. For wheel throwing, ensure your pottery wheel is clean and properly set up. For hand-building, a canvas-covered board or similar non-stick surface is ideal.

- Tools: Gather necessary pottery tools such as wire cutters, sponges, ribs, and cutting tools.

Image 2.1: The Laguna Rod's BOD WC823 clay in its raw, packaged form.

3. Operating Instructions (Working with Clay)

This clay is suitable for various ceramic techniques, including wheel throwing and hand-building.

3.1. Wheel Throwing

- Centering: Place a wedged lump of clay firmly on the center of the pottery wheel. Use water and steady pressure to center the clay.

- Opening and Pulling: Once centered, open the clay to form the base and then pull the walls upwards to create your desired form. Maintain consistent moisture to prevent the clay from tearing.

- Shaping: Use various tools and hand techniques to shape the piece. The medium coarse texture provides good workability.

- Trimming: After the piece has reached a leather-hard stage, it can be trimmed to refine its shape and foot.

3.2. Hand-Building

- Slab Construction: Roll out slabs of uniform thickness. Score and slip edges before joining to ensure strong bonds.

- Coil Building: Roll coils of clay and stack them, blending each coil thoroughly to prevent weak points.

- Pinch Pots: Start with a ball of clay and pinch outwards to create a form.

3.3. Drying and Firing

- Drying: Allow pieces to dry slowly and evenly to prevent warping and cracking. Cover with plastic for the initial drying stages to control moisture loss.

- Bisque Firing: Fire to a bisque temperature (typically Cone 04-06) to harden the clay and prepare it for glazing.

- Glazing: Apply glazes suitable for Cone 10 firing. Consider the clay's reduction firing characteristics (medium brown with iron specks) when selecting glazes, as these specks may interact with and bleed into the glaze.

- High Firing: Fire to Cone 10 (approximately 2381°F or 1305°C). The final color will depend on the kiln atmosphere (oxidation or reduction).

4. Maintenance and Storage

Proper storage and maintenance will extend the life of your clay and ensure optimal workability.

- Storing Unused Clay: Keep unused clay tightly wrapped in its original plastic bag or an airtight container to prevent it from drying out. If the clay begins to stiffen, a small amount of water can be added and wedged in.

- Reclaiming Clay: Dried-out clay scraps can often be reclaimed by breaking them into small pieces, soaking them in water, and then wedging them back to a workable consistency.

- Clean-up: Clean tools and work surfaces immediately after use to prevent clay from hardening and becoming difficult to remove. Avoid washing large amounts of clay down drains to prevent plumbing issues.

5. Troubleshooting Common Issues

Addressing common problems can help improve your pottery results.

| Issue | Possible Cause | Solution |

|---|---|---|

| Cracking during drying | Uneven drying, too rapid drying, or inconsistent wall thickness. | Ensure slow, even drying. Cover pieces with plastic to control moisture loss. Maintain uniform wall thickness. |

| Cracking during firing | Air bubbles in the clay, insufficient drying, or rapid temperature changes in the kiln. | Thoroughly wedge clay to remove air bubbles. Ensure pieces are bone dry before firing. Follow proper kiln firing schedules. |

| Difficulty centering on the wheel | Insufficient wedging, improper body posture, or inconsistent pressure. | Wedge clay thoroughly. Practice proper body mechanics and apply steady, even pressure. |

| Glaze defects (e.g., crawling, pinholes) | Improper glaze application, dusty bisque ware, or incompatible glaze/clay body. | Clean bisque ware before glazing. Apply glazes evenly. Ensure glazes are compatible with Cone 10 firing and the clay body. |

6. Product Specifications

| Specification | Detail |

|---|---|

| Brand | Laguna |

| Model Number | WC823 |

| Cone Rating | 10 |

| Wet Color | Light Gray |

| Fired Color (Oxidation) | Yellow/Buff |

| Fired Color (Reduction) | Medium Brown |

| Texture | Medium Coarse |

| Average Shrinkage (±2%) | 13.5% |

| Material | Clay |

| Item Weight | 25 pounds |

| Product Dimensions (L x W x H) | 12 x 9 x 4 inches |

| Recommended Uses | Modeling, Pottery |

| Date First Available | November 17, 2022 |

7. Important Safety Information

Always handle clay in a well-ventilated area. Avoid inhaling dry clay dust, as it can contain silica which may cause respiratory issues. Use appropriate personal protective equipment, such as a dust mask, when working with dry clay or sanding fired pieces. Wash hands thoroughly after handling clay.

8. Warranty and Support

For questions regarding the quality or performance of Laguna Rod's BOD WC823 clay, please contact Laguna Clay directly. Information regarding specific product warranties and customer support can be found on the manufacturer's official website or by contacting their customer service department.

Manufacturer: Laguna Clay