1. Safety Precautions

Always prioritize safety when operating the ANCEL AJ400 GDI Injector Cleaning Machine. Failure to follow these guidelines may result in injury or damage to the equipment.

- No Naked Flame: Ensure there are no naked flames or ignition sources within 2 meters (approximately 6.5 feet) of the machine during operation.

- Eye Protection: Always wear appropriate eye protection, such as safety goggles, to prevent contact with cleaning solutions or fuel.

- Hand Protection: Wear chemical-resistant gloves to protect your hands from cleaning agents and fuel.

- Electrical Safety: Ensure the machine is properly grounded and connected to a stable power supply (110V as specified). Avoid operating with wet hands or in damp environments.

- Ventilation: Operate the machine in a well-ventilated area to prevent the buildup of hazardous fumes.

- Emergency Shutdown: Familiarize yourself with the power switch location for quick shutdown in emergencies. The fuel circuit depressurization technology automatically depressurizes the machine in case of sudden shutdown.

2. Package Contents

Before beginning, verify that all components are present in your package. If any items are missing or damaged, please contact customer support.

- ANCEL AJ400 GDI Injector Cleaning Machine (Main Unit)

- Main Pulse Cable

- Fuel Separator Assembly

- Extended Pole

- Pulse Signal Cable

- Power Cable

- Resistance Test Cable

- Vice Adaptor

- Fuel Separator Stopper

- Universal GDI Adaptor

- Main Adaptor

- Lock Handwheel

- GM GDI Adaptor

- Thread GDI Adaptor

- User's Manual (PDF version available online)

- Injector Shims

- O-ring assortment

3. Setup Guide

3.1 Unboxing and Initial Assembly

Carefully unbox the ANCEL AJ400 GDI machine and its components. The main unit is securely packed with protective foam. Remove all packaging materials.

3.2 Installing Glass Tubes and Fuel Outlet Pipe

Install the glass tubes onto the main unit. Ensure they are securely seated. Connect the fuel outlet pipe to the designated port on the machine.

4. Operating Instructions

4.1 Connecting Injectors

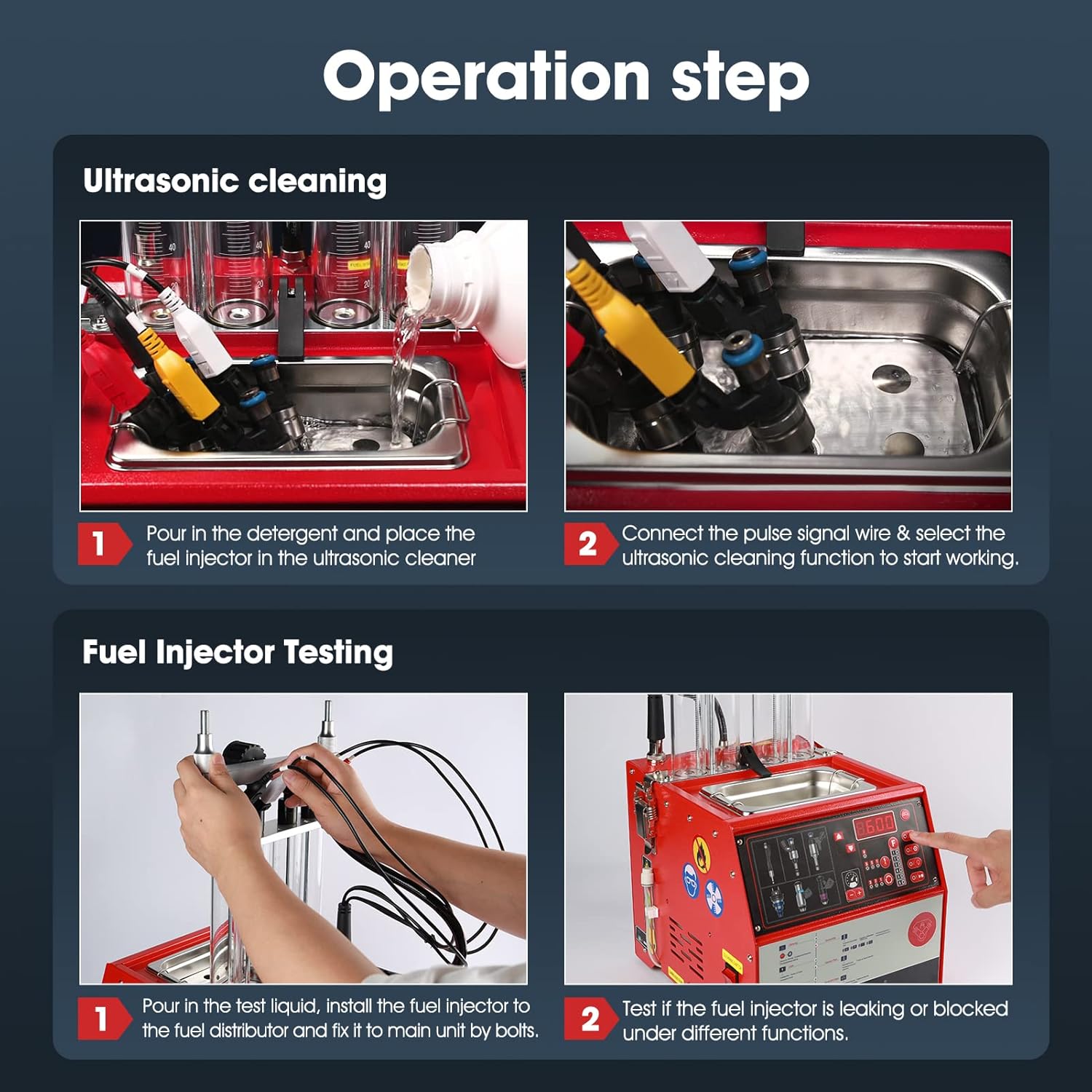

Connect the fuel injectors to the fuel distributor assembly. Ensure a secure connection to prevent leaks during testing. Use the appropriate adaptors for different injector types (standard, GDI, etc.).

4.2 Fuel Injector Testing

The ANCEL AJ400 GDI supports various testing functions to assess injector performance.

Resistance Test

This test measures the electrical resistance of each injector to identify potential electrical faults. Connect the resistance test cable to the injector and observe the reading on the display.

Uniformity / Sprayability Test

This test evaluates the consistency of fuel injection quantity and the atomization pattern of each injector. Observe the spray pattern and the liquid levels in the glass tubes.

Leakage Test

This test checks for any leakage from the injector nozzle when under pressure, ensuring proper sealing performance.

Injecting Flow Test

Measures the amount of fuel injected over a specific time period to determine the injector's flow rate and identify any blockages.

Working Modes Test

Simulates various engine working conditions (e.g., acceleration, deceleration) to comprehensively test injector performance under different loads.

4.3 Ultrasonic Cleaning

The ultrasonic cleaning function uses high-frequency sound waves to effectively remove carbon deposits and impurities from the injectors. The AJ400 GDI also features a heating function to improve cleaning efficiency.

5. Maintenance

5.1 Motherboard Replacement

In the event of a motherboard issue, it can be replaced. This procedure should only be performed by qualified personnel. Ensure the machine is unplugged and all safety precautions are followed.

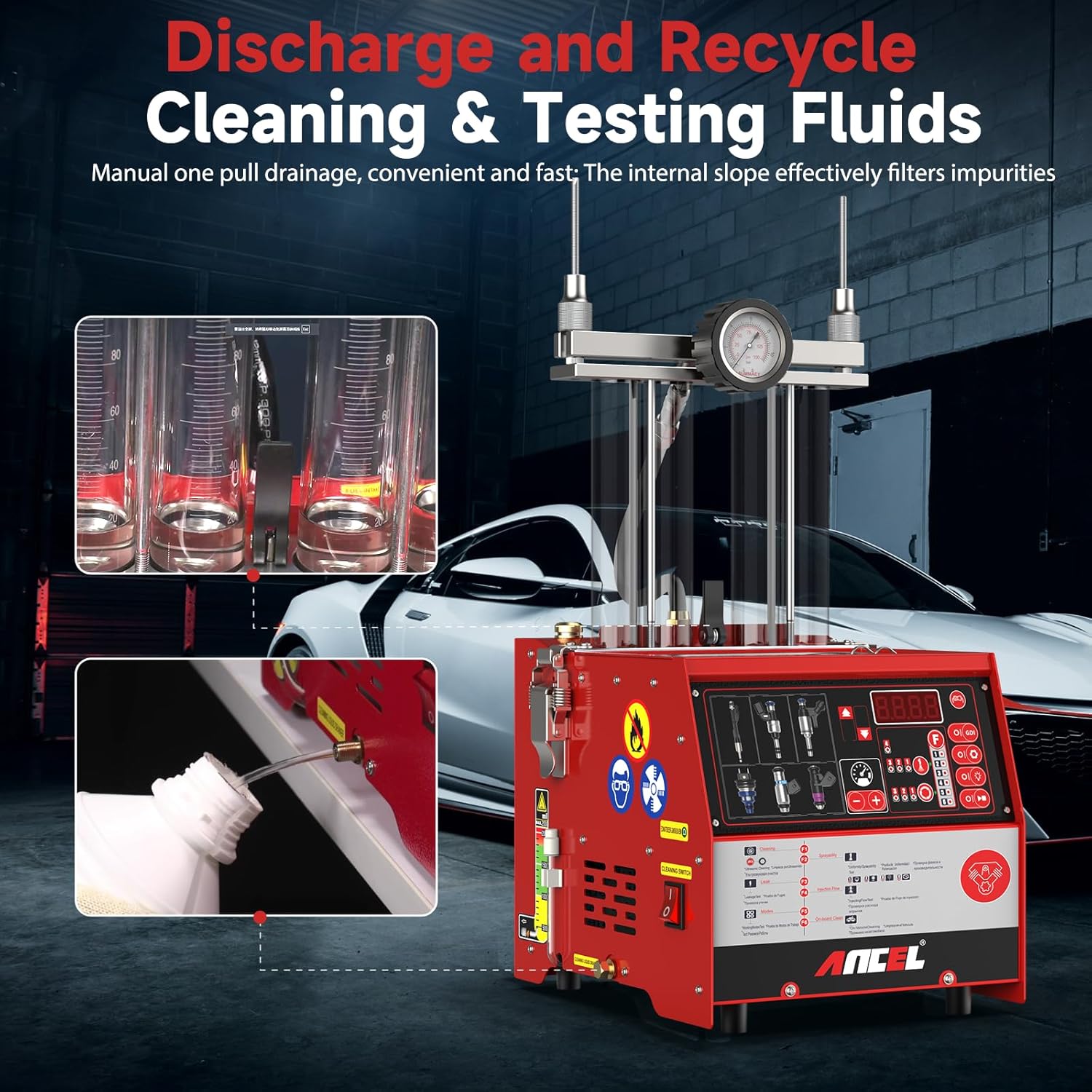

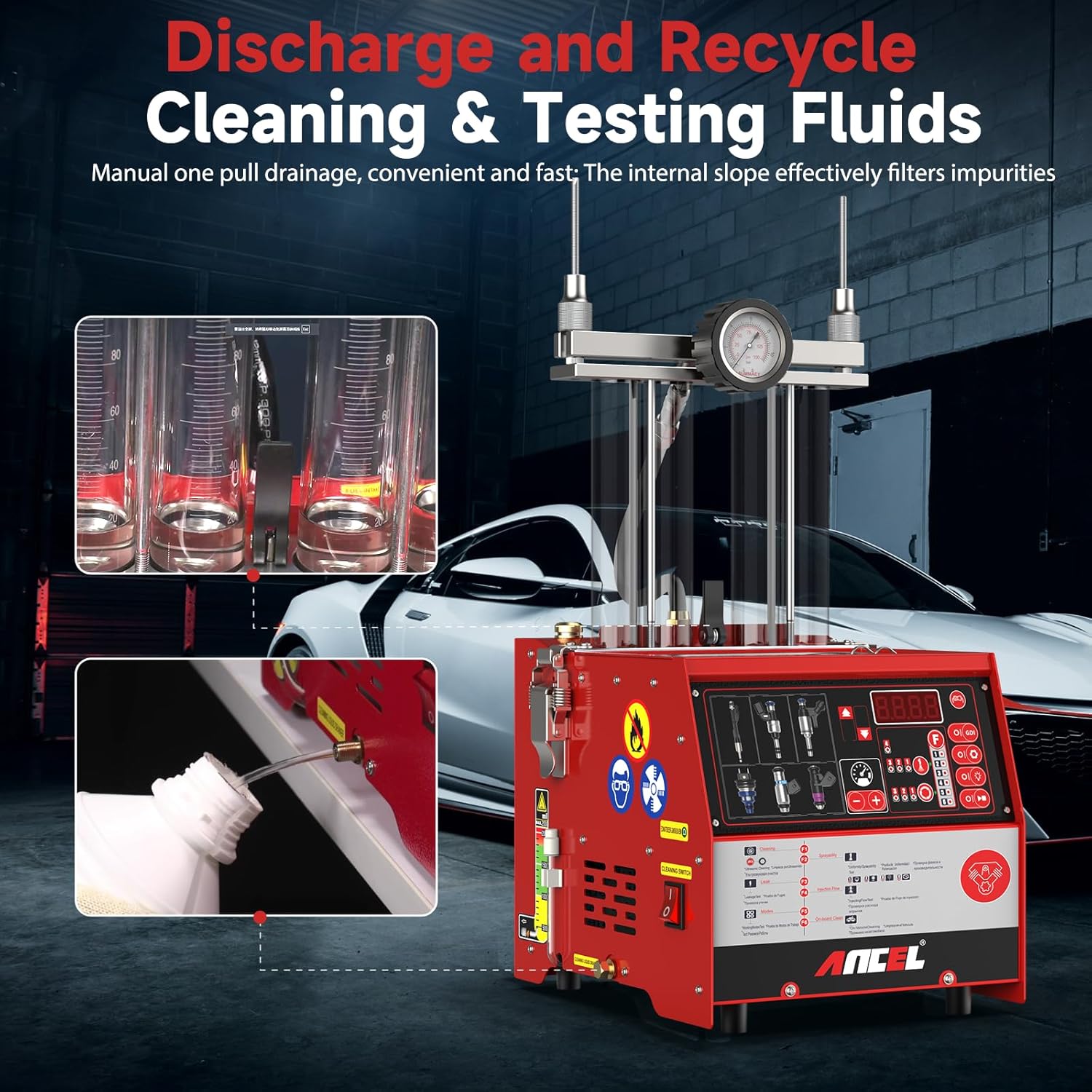

5.2 Cleaning Solution Discharge and Recycle

After cleaning and testing, the used solution can be discharged and recycled through the designated drain port. The built-in slope design helps filter impurities, promoting environmental friendliness and cost savings.

6. Troubleshooting

If you encounter any issues with your ANCEL AJ400 GDI Injector Cleaning Machine, please refer to the following general troubleshooting steps:

- Power Issues: Ensure the power cable is securely connected and the power switch is in the 'ON' position. Verify the power outlet is functional.

- Display Not Working: Check power connections. If the issue persists, contact customer support.

- No Spray/Uneven Spray: Verify injectors are correctly installed and connected. Ensure sufficient cleaning solution/test fluid. Check for blockages in the injectors or fluid lines.

- Pressure Irregularities: Check the fuel pressure gauge. Ensure all connections are tight and there are no leaks.

- Error Codes: If an error code appears on the LED display, consult the detailed user manual (PDF) for specific code meanings and resolutions.

For complex issues or problems not covered here, please contact ANCEL customer service for expert assistance.

7. Technical Specifications

Below are the key technical specifications for the ANCEL AJ400 GDI Injector Cleaning Machine:

| Specification | Value |

|---|---|

| Model | AJ400 GDI |

| Main Unit Power Supply | AC110V±10% 60Hz (Fit for US) |

| Input Power | 230W |

| Ultrasonic Cleaner Power | 100W |

| Resistance Test Accuracy | 0.1Ω |

| Simulated RPM Range | 100 - 9900rpm (step: 10rpm) |

| Time Range | 5 ~ 300s (step: 5s) |

| Pulse Width | 0.1 ~ 25ms (step: 0.1ms) |

| Fuel Tank Capacity | 2000ml |

| Work Pressure | 0-7bar |

| Item Weight | 24.8 pounds |

| Product Dimensions | 14.17 x 14.17 x 15.75 inches |

8. Warranty and Customer Support

The ANCEL AJ400 GDI fuel injector cleaner and tester comes with a 24-month warranty to ensure your peace of mind. ANCEL is committed to providing excellent customer service.

- Customer Service: ANCEL offers 7x24 hour friendly customer service. If you have any questions or require assistance, please do not hesitate to contact us.

- Warranty Claims: No additional fees are required for warranty services.

For more information or to explore other ANCEL products, please visit the ANCEL Store on Amazon.