1. Introduction

Thank you for choosing the ENJOYWOOD E20 Laser Engraver and Cutter. This machine is designed for precision engraving and cutting a variety of materials, featuring a powerful 20W laser output and advanced compressed spot technology. This manual provides essential information for safe operation, setup, maintenance, and troubleshooting to ensure optimal performance and longevity of your device.

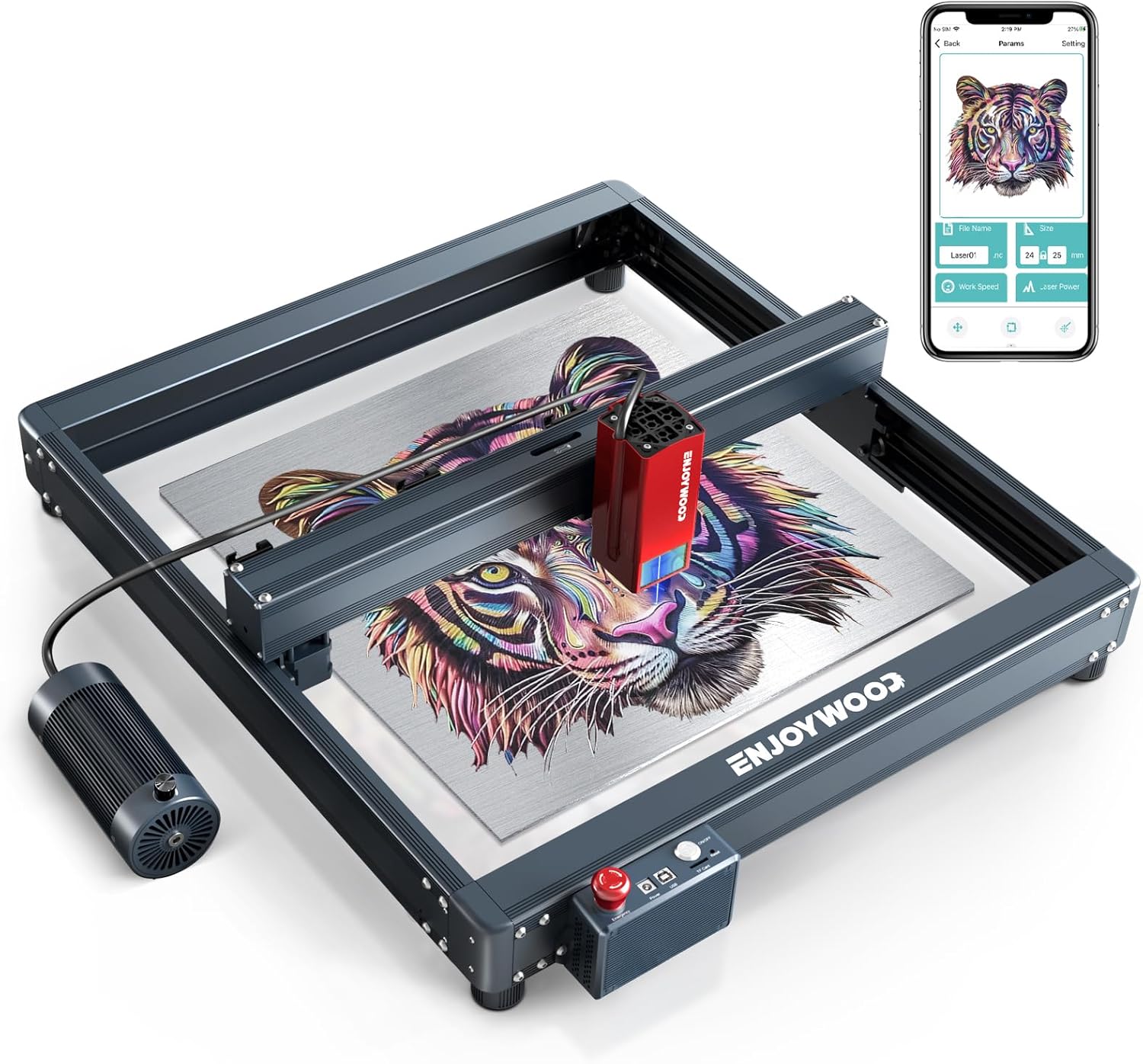

Figure 1.1: The ENJOYWOOD E20 Laser Engraver in operation, demonstrating its capability to engrave intricate designs. A mobile application interface is shown on a smartphone, indicating remote control functionality.

2. Safety Instructions

Operating a laser engraver involves potential hazards. Adhere strictly to the following safety guidelines to prevent injury and damage to the equipment.

- Eye Protection: Always wear the provided laser safety goggles when the machine is operating. The panoramic filter glass protective cover filters 97% of UV light, but direct exposure to the laser beam can cause permanent eye damage.

- Ventilation: Operate the machine in a well-ventilated area to dissipate fumes and smoke produced during engraving and cutting.

- Fire Safety: Keep a fire extinguisher nearby. Certain materials can ignite during laser processing. Never leave the machine unattended while operating.

- Emergency Stop: The E20 is equipped with an emergency stop button. In case of any malfunction or emergency, press this button immediately to halt all operations.

- Material Compatibility: Only engrave or cut materials specified as safe for laser processing. Avoid materials that produce toxic fumes or are highly flammable.

- Physical Contact: Do not touch the laser module or the engraving area during operation. The laser module can be hot, and moving parts can cause injury.

- Children and Pets: Keep children and pets away from the operating area.

- Power Supply: Use only the specified power adapter. Ensure the power supply is stable and properly grounded.

- XY Axis Limit Switches: The machine includes XY axis limit switches to prevent the laser head from exceeding the working area, enhancing safety.

- Move/Tip Instant Stop: The machine is designed to stop instantly if moved or tipped during operation, adding an extra layer of safety.

Figure 2.1: Overview of the ENJOYWOOD E20's multiple security protection measures, including eye protection, limit switches, movement detection, and the emergency stop button.

3. Product Features

The ENJOYWOOD E20 Laser Engraver and Cutter incorporates several advanced features for enhanced performance and user experience:

- 20W Output Power Laser: Utilizes the latest four 6W laser coupling technology, providing a powerful 20W output for efficient engraving and cutting. Capable of cutting 12-15mm tung boards, 8mm black acrylic boards, and 0.05mm stainless steel sheets in a single pass.

- Upgraded Compressed Spot Technology: The ultra-fine laser focus area is reduced to 0.08 x 0.1mm, allowing for high-density laser application. This enables cutting of 25mm thick wood and 30mm thick black acrylic, with carving and cutting speeds up to 40% higher than standard models.

- Enhanced Engraving Accuracy: Features a newly upgraded 32-bit motherboard with a built-in 256-bit color scale diagram, resulting in more refined engravings with higher contrast. The all-aluminum alloy anodized structure ensures durability and improved carving precision.

- Integrated Air Assist System: Equipped with a standard air assist kit, significantly improving cutting ability, accuracy, and quality by reducing scorch marks and clearing debris. The built-in design ensures a clean setup without external wires.

- Offline Engraving Support: Includes a terminal control panel for offline engraving, allowing operation without a continuous computer connection.

- Eye Protection Design: Features a panoramic filter glass protective cover that filters 97% of UV light, allowing observation of the engraving process without additional goggles for bystanders.

- Multiple Security Measures: Incorporates an emergency stop button, XY axis limit switches, and a move/tip instant stop function for enhanced operational safety.

Figure 3.1: Illustration of the dual compression spot coupling technology, detailing how four 6W lasers combine to create a powerful 20W output with a fine spot size of 0.08 x 0.14mm, enabling efficient cutting of various materials.

Figure 3.2: Speed comparison demonstrating the ENJOYWOOD E20's high-speed engraving capability at 400 mm/s, significantly faster than other models, while maintaining quality.

Figure 3.3: Depiction of the newly upgraded 32-bit motherboard with a built-in 256-bit color palette, highlighting the machine's ability to produce detailed and colorful engravings.

Figure 3.4: Visual comparison demonstrating the effectiveness of the integrated air assist system in producing smooth and clean engravings by reducing scorch marks.

4. Setup and Assembly

Follow these steps to assemble and set up your ENJOYWOOD E20 Laser Engraver:

- Unpacking: Carefully remove all components from the packaging. Verify that all parts listed in the packing list are present and undamaged.

- Frame Assembly: Assemble the aluminum alloy frame according to the included assembly guide. Ensure all screws are tightened securely to maintain structural rigidity and engraving accuracy.

- Laser Module Installation: Mount the laser module onto the gantry. Connect the necessary cables to the laser module and the main control board.

- Air Assist Connection: Connect the air assist hose from the integrated air pump to the laser module.

- Power Connection: Connect the power adapter to the machine and then to a suitable power outlet.

- Software Installation: Install the recommended engraving software (e.g., LaserGRBL, LightBurn) on your computer. The ENJOYWOOD E20 is compatible with MacOS and Windows.

- Connectivity: Connect the machine to your computer via USB, or utilize WiFi/TF card for offline engraving. The Enjoywood App is also available for control.

- Initial Test: Perform a small test engraving on a scrap piece of material to verify proper functionality and laser focus.

Figure 4.1: The ENJOYWOOD E20 demonstrating its wide compatibility and multiple connection options, including USB, WiFi, TF card, and dedicated app support for various operating systems like MacOS and Windows.

5. Operating Instructions

5.1 Preparing for Engraving/Cutting

- Material Placement: Place the material to be processed flat on the working surface. Ensure it is securely positioned and does not move during operation.

- Focus Adjustment: Adjust the laser focus according to the material thickness. Refer to the specific instructions for your laser module for precise focusing.

- Software Setup: Open your chosen engraving software (e.g., LaserGRBL, LightBurn). Import your design and adjust parameters such as power, speed, and passes based on the material type and desired outcome.

- Work Area Definition: Define the work area in the software to match the physical placement of your material.

5.2 Starting Operation

- Initiate Job: Once all parameters are set and safety precautions are observed, start the engraving or cutting job from the software or the machine's terminal control panel for offline engraving.

- Monitoring: Continuously monitor the machine during operation. Observe for any unusual smells, smoke, or signs of fire.

- Air Assist: Ensure the integrated air assist system is active for cutting operations or when engraving materials prone to scorching.

5.3 Offline Engraving

The E20 supports offline engraving via its terminal control panel or TF card. Prepare your G-code file using compatible software, transfer it to a TF card, insert the card into the machine, and select the file from the control panel to begin engraving without a computer connection.

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your ENJOYWOOD E20.

- Cleaning the Laser Lens: Periodically clean the laser lens using a specialized lens cleaning solution and a lint-free cloth or cotton swab. A dirty lens can reduce laser power and engraving quality.

- Cleaning the Work Area: Remove debris and dust from the engraving bed and surrounding areas after each use. This prevents accumulation that could interfere with machine movement or pose a fire hazard.

- Lubrication: Apply a small amount of lubricant to the guide rails and lead screws every few months to ensure smooth movement of the laser module.

- Firmware Updates: Check the official ENJOYWOOD website for any available firmware updates to ensure your machine has the latest features and bug fixes.

- Air Assist System: Ensure the air assist nozzle is clear of any blockages.

7. Troubleshooting

Refer to the following common issues and their potential solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Laser not firing or weak output |

|

|

| Machine not connecting to computer |

|

|

| Engraving quality is poor or inconsistent |

|

|

| Machine stops unexpectedly |

|

|

8. Specifications

| Feature | Detail |

|---|---|

| Model | ENJOYWOOD E20 |

| Laser Output Power | 20W (four 6W laser coupling technology) |

| Laser Spot Size | 0.08 x 0.1mm (Compressed Spot) |

| Motherboard | Upgraded 32-bit with 256-bit color scale |

| Engraving/Cutting Speed | Up to 400 mm/s |

| Cutting Capability (Single Pass) | 12-15mm Tung Boards, 8mm Black Acrylic, 0.05mm Stainless Steel |

| Air Assist System | Integrated |

| Eye Protection | Panoramic Filter Glass Protective Cover (filters 97% UV) |

| Safety Features | Emergency Stop Button, XY Axis Limit Switches, Move/Tip Instant Stop |

| Connectivity | USB, WiFi, TF Card, App (Enjoywood App) |

| Operating Systems | MacOS, Windows |

| Date First Available | 27 July 2022 |

| ASIN | B0B7RPPJ17 |

9. Warranty and Support

For warranty information and technical support, please refer to the official ENJOYWOOD website or contact their customer service directly. Keep your purchase receipt as proof of purchase for warranty claims.

For the latest drivers, software, and troubleshooting guides, visit the ENJOYWOOD support page.