1. Introduction and Overview

The Neoteck 0-1" Digital Dial Indicator Table Saw Gauge is a precision tool designed for accurate alignment and calibration of various workshop machinery, including table saws, band saws, and drill presses. It ensures your equipment operates at its best condition, providing precise measurements for critical adjustments.

Key features include a professional design suitable for standard miter grooves (3/8 inch x 3/4 inch), an accurate digital dial indicator with a 0-1 inch (0-25.4 mm) measuring range and high resolution up to 0.0005 inch (0.01 mm), and durable CNC-machined anodized aluminum bars. The indicator offers switchable inch/mm units and a zero-setting function for convenient use.

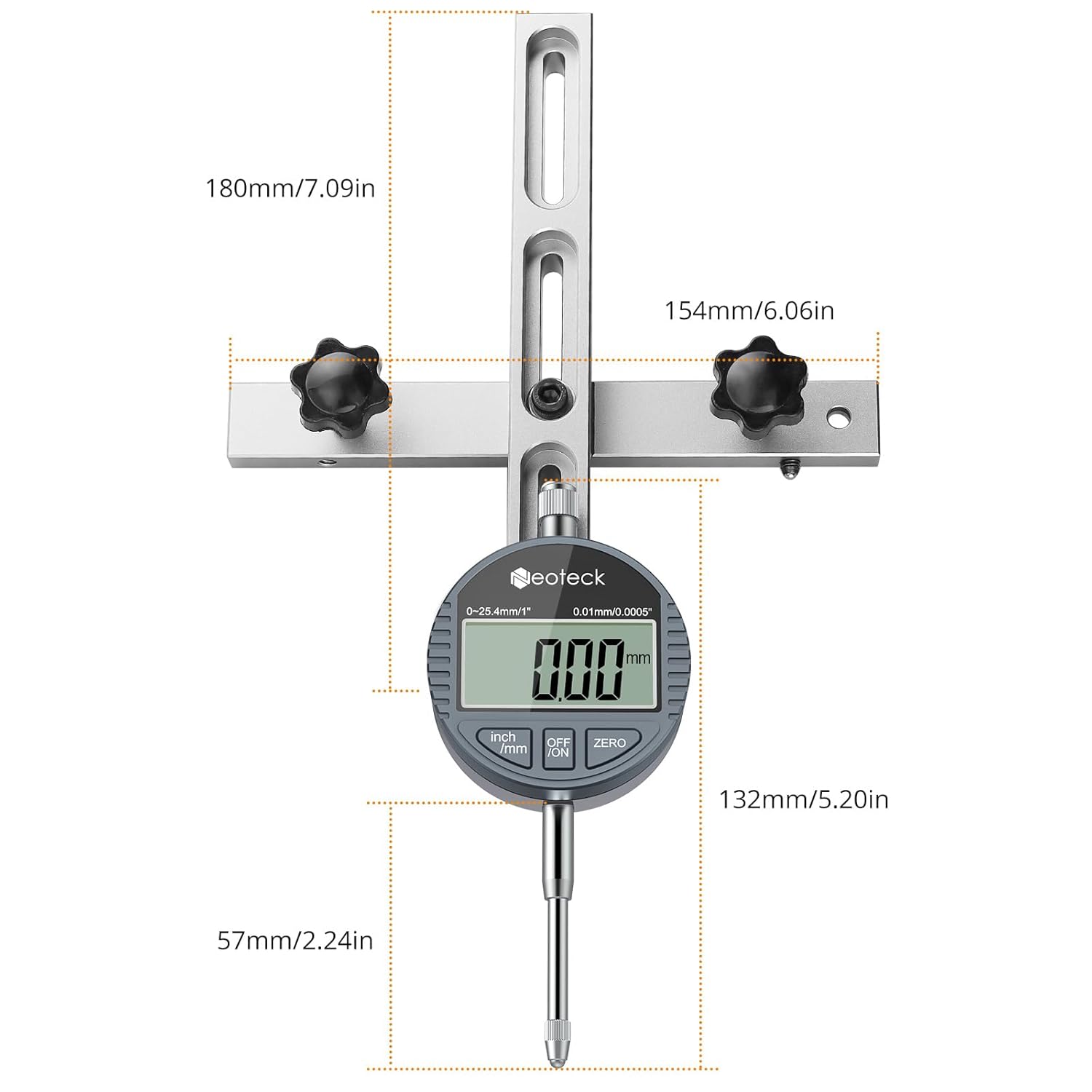

Figure 1.1: Neoteck Digital Dial Indicator Table Saw Gauge with 3/4" (19mm) Width Aluminum Alloy Bars, highlighting its range and resolution.

Video 1.1: An overview of the Neoteck 0-1" Digital Table Saw Gauge, demonstrating its features and applications.

2. What's in the Box

Your Neoteck Digital Table Saw Gauge Set includes the following components:

- 1 x Digital Dial Indicator

- 1 x Back Cover

- 2 x Plum Blossom Nuts

- 2 x Spring Plungers

- 2 x Hexagon Socket Nuts

- 2 x Hexagon Socket Wrenches

- 2 x Metal Shop Bars

- 1 x User Manual

Figure 2.1: All components included in the Neoteck Digital Dial Indicator Table Saw Gauge Set.

Video 2.1: An unboxing video demonstrating the contents of the Neoteck table saw gauge package.

3. Setup Instructions

Follow these steps to assemble and prepare your Neoteck Digital Dial Indicator Table Saw Gauge for use:

- Assemble the Bars: Use the included hexagon socket wrench to set up the two aluminum bars, forming a cross-frame structure. Ensure they are securely fastened.

- Adjust Spring Plungers: Tighten the plum blossom nuts to adjust the spring plungers. This allows you to change the width and height of the chamfered groove rod, ensuring a snug fit in miter slots of 3/4" (19mm) or more. Adjust via screws for optimal fit if the groove width exceeds 3/4" (19mm).

- Install Digital Indicator: Attach the digital dial indicator to the end of the assembled bar using the provided back cover and hexagon socket nut. Ensure it is firmly secured.

Figure 3.1: Visual guide for installing the bars, tightening nuts, adjusting spring plungers, and installing the indicator.

Figure 3.2: Detail of the built-in spring screw and adjustable nuts for customizing the gauge's fit.

Video 3.1: A demonstration of how to assemble and set up the digital table saw gauge.

4. Operating Instructions

The digital dial indicator provides precise measurements for various alignment tasks:

- Power On/Off: Press the 'ON/OFF' button to turn the indicator on or off.

- Unit Conversion: Press the 'inch/mm' button to switch between imperial (inches) and metric (millimeters) units.

- Zero Setting: Press the 'ZERO' button to reset the display to zero at any point. This allows for relative measurements.

- Checking Saw Blade Alignment: Insert the assembled gauge into your table saw's miter slot. Position the indicator's contact point against the saw blade. Gently move the gauge along the miter slot, observing the digital display for any variations in measurement. This indicates blade run-out or misalignment.

- Checking Fence Straightness: Place the gauge against your table saw fence and move it along the fence's length to check for straightness and parallelism to the blade.

- Other Applications: The gauge can also be used to check drill chuck run-out, jointer depth of cut, and other precise measurements for various workshop machines.

Figure 4.1: The 0-1" / 0-25.4 mm indicator with 0.0005" / 0.01mm accuracy, showing convenient ports, contact point type, and anti-dust cap.

Figure 4.2: Demonstrations of checking saw blade alignment and run-out, fence straightness, drill chuck run-out, and jointer depth of cut.

Video 4.1: A demonstration of the digital indicator's on/off, inch/mm conversion, and zero-setting functions.

Video 4.2: A demonstration of how to use the table saw gauge to check blade alignment.

5. Specifications

| Attribute | Value |

|---|---|

| Brand | Neoteck |

| Model Number | WT392 |

| Material | Aluminum |

| Product Dimensions | 4.8"L x 0.75"W |

| Range | 0-1 Inches (0-25.4 mm) |

| Measurement Accuracy | 0.0005" (0.01 mm) |

| Number of Batteries | 1 LR44 (included) |

| Item Weight | 1.3 pounds |

| Date First Available | June 30, 2022 |

Figure 5.1: Detailed dimensions of the Neoteck Digital Dial Indicator Table Saw Gauge components.

6. Maintenance

To ensure the longevity and accuracy of your Neoteck Digital Dial Indicator Table Saw Gauge, follow these maintenance guidelines:

- Cleaning: Regularly wipe down the gauge and its components with a soft, dry cloth. Avoid using harsh chemicals or abrasive materials that could damage the finish or electronic components.

- Storage: Store the gauge in its protective case when not in use to prevent dust accumulation and physical damage. Keep it in a dry environment away from extreme temperatures.

- Battery Replacement: The digital indicator requires one LR44 battery. Replace the battery when the display becomes dim or unresponsive. Refer to Figure 4.1 for the battery compartment location.

- Handle with Care: Avoid dropping or subjecting the gauge to strong impacts, as this can affect its calibration and accuracy.

7. Troubleshooting

If you encounter issues with your Neoteck Digital Dial Indicator Table Saw Gauge, consider the following:

- Inaccurate Readings:

- Ensure the contact point is clean and free of debris.

- Verify that the gauge is securely installed in the miter slot and the indicator is firmly attached.

- Check for any physical damage to the indicator or bars.

- Perform a zero-setting calibration before taking measurements.

- Display Not Working:

- Check if the battery is correctly installed.

- Replace the LR44 battery with a new one.

- Ensure the 'ON/OFF' button is pressed firmly.

- Loose Fit in Miter Slot:

- Adjust the plum blossom nuts and spring plungers to achieve a tighter fit.

- Confirm your miter slot width is 3/4" (19mm) or more, as specified.

For further assistance, please contact Neoteck customer support.

8. Warranty and Support

Neoteck products are designed for quality and reliability. For information regarding warranty coverage, product support, or to report any issues, please refer to the contact information provided with your purchase or visit the official Neoteck website. Keep your purchase receipt as proof of purchase for warranty claims.