1. Product Overview

The WOODS OEM 19459 Friction Disc is a genuine replacement part designed for various WOODS multi-spindle and cutter tractor attachments. This component is crucial for the proper operation of your equipment, ensuring efficient power transfer and reliable performance.

Figure 1: WOODS 19459 Friction Disc (Top View)

Figure 2: WOODS 19459 Friction Disc (Angled View)

2. Key Features and Benefits

- Genuine OEM Part: Manufactured exclusively to Woods’ superior standards, ensuring compatibility and optimal performance.

- Superior Performance: Designed to provide reliable power transfer and durability, surpassing aftermarket alternatives.

- Enhanced Efficiency: Contributes to maintaining a productive work area by ensuring efficient operation of your equipment.

- Precision and Quality: Engineered for precise fit and function, supporting a professionally maintained landscape.

- Durable Construction: Built to withstand demanding conditions, ensuring longevity and consistent operation.

3. Compatibility Information

The WOODS 19459 Friction Disc is compatible with a wide range of WOODS equipment models. Please verify your equipment's manual for the exact part number required. Compatible models include, but are not limited to:

- 121, 1260, 208, 2120, 2126, 2162, 3168, 3180, 3240

- B106, B214, B320

- C114, DS1260, DS1440, DSO1260

- HD210, HD315

- M121, M208, MB106, MD160, MD172, MD184, MD315, MDC172, MDP160, MDP172, MDP184, MR105

- O121, O2126

- R105, RB1010, RB750, RB850, RB880, RB990

- TS1680

- XT148, XT160, XT172, XT184

Using genuine WOODS replacement parts ensures a smooth and reliable experience with your machinery.

4. Installation and Setup

Installation of the WOODS 19459 Friction Disc should be performed by a qualified technician or an individual with experience in agricultural and lawn equipment maintenance. Always refer to your specific equipment's service manual for detailed, step-by-step instructions.

4.1 Safety Precautions

- Ensure the equipment is turned off, disengaged, and all moving parts have come to a complete stop.

- Disconnect the power source (e.g., remove spark plug wire, disconnect battery, or disengage PTO).

- Wear appropriate personal protective equipment (PPE), including safety glasses and gloves.

- Secure the equipment to prevent accidental movement during installation.

4.2 General Installation Steps (Consult Equipment Manual for Specifics)

- Locate the friction disc assembly within your equipment. This typically involves accessing the clutch or power transfer mechanism.

- Carefully remove any covers or housings to expose the worn friction disc.

- Note the orientation and position of the existing disc and any associated components (e.g., springs, plates).

- Remove the old friction disc. Inspect surrounding components for wear or damage and replace as necessary.

- Clean the mating surfaces thoroughly to ensure proper contact with the new disc.

- Install the new WOODS 19459 Friction Disc, ensuring it is correctly seated and oriented according to your equipment's manual.

- Reassemble all components, tightening fasteners to the manufacturer's specified torque values.

- Before operating, perform a functional check to ensure the disc engages and disengages properly.

Figure 3: Example of a power transfer component on WOODS equipment.

5. Operating Considerations

Once the new friction disc is installed, operate your equipment according to the manufacturer's guidelines. The friction disc facilitates smooth engagement and disengagement of power to the attachment. Proper operation helps extend the life of the disc and associated components.

- Avoid sudden or harsh engagement of the clutch or power take-off (PTO) to prevent premature wear on the friction disc.

- Ensure the equipment is operating at the recommended RPMs for the task to optimize power transfer and minimize slippage.

- If you notice any unusual noises, vibrations, or a decrease in power transfer, cease operation and inspect the friction disc and related components.

Figure 4: WOODS equipment in operation.

6. Maintenance

Regular inspection and maintenance of your friction disc and related components are essential for prolonging the life of your WOODS equipment. While the friction disc itself is a wear item, proper care can maximize its lifespan.

6.1 Inspection Schedule

- Before Each Use: Briefly check for any obvious signs of damage or loose components in the general area of the power transfer.

- Every 50 Hours of Operation or Annually (whichever comes first):

- Inspect the friction disc for signs of excessive wear, glazing, cracking, or chipping.

- Check for proper engagement and disengagement.

- Examine associated components like pressure plates, springs, and bearings for wear or damage.

- Ensure all fasteners are tight and secure.

6.2 Cleaning and Storage

- Keep the friction disc and surrounding area free from excessive dirt, debris, oil, and grease, which can impair performance.

- When storing equipment for extended periods, ensure the friction disc is disengaged to prevent it from sticking.

7. Troubleshooting

If you encounter issues with power transfer or the performance of your equipment after installing the friction disc, consider the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Slippage or Loss of Power |

|

|

| Difficulty Engaging/Disengaging |

|

|

| Unusual Noises (e.g., Squealing, Grinding) |

|

|

If problems persist after attempting these solutions, it is recommended to consult a certified WOODS service technician.

8. Specifications

| Attribute | Value |

|---|---|

| Model Number | 19459 |

| Brand | WOODS |

| Product Dimensions | 6.25 x 6.25 x 0.25 inches |

| Item Weight | 2.88 ounces |

| Part Type | Friction Disc |

| Compatibility | Compatible with various WOODS multi-spindle and cutter tractor attachments (see Section 3 for details). |

9. Warranty and Support

For specific warranty information regarding your WOODS OEM 19459 Friction Disc, please refer to the documentation provided with your original equipment or contact WOODS directly. As a genuine OEM part, it is designed to meet the high standards of WOODS products.

For technical support, replacement part inquiries, or service assistance, please visit the official WOODS website or contact their customer service department. You can find more information about WOODS products and support at the WOODS Store on Amazon or their official corporate site.

Figure 5: WOODS Genuine Parts Logo

10. About WOODS

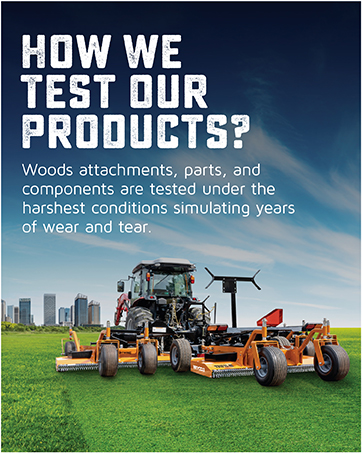

WOODS has a long-standing reputation for manufacturing high-quality, durable parts and attachments for agricultural and lawn care needs. With over 75 years of experience, they are committed to engineering, improving, and rigorously testing their equipment to excel in the field.

Video 1: WOODS Shared Values. This video highlights the brand's commitment to quality, innovation, and customer satisfaction, showcasing their manufacturing processes and the use of their equipment in various settings.

Figure 6: Quality manufacturing processes at WOODS.

Figure 7: Rigorous product testing ensures durability.