1. Product Overview

The WEDO Hexagonal Non-Sparking Chisel is a specialized hand tool designed for safety in hazardous environments. Constructed from high-quality beryllium copper, this chisel is non-sparking and non-magnetic, making it suitable for use in areas where flammable or explosive materials are present. It adheres to strict DIN standards and is BAM and FM certified, ensuring reliability and performance.

Figure 1: Full view of the WEDO Hexagonal Non-Sparking Chisel.

This chisel features an advanced forging process, resulting in high hardness and strong torque. Its design includes an arc angle to protect nuts and an improved striking end to prevent flashing and chipping during use. The surface color is a distinctive golden yellow.

2. Safety Information

The primary safety feature of this chisel is its non-sparking property. This tool is specifically engineered to prevent the generation of sparks when friction or impact occurs between the tool and a workpiece. This is crucial for preventing flammable explosions and ensuring both national property and personal safety in high-risk environments.

- Always inspect the chisel for any damage before use.

- Ensure the work area is clear of obstructions and potential hazards.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and sturdy footwear.

- Do not use the chisel if the hydrogen concentration in the environment exceeds 21%.

- Store the chisel in a dry, safe place away from corrosive materials.

Figure 2: Detail showing the Beryllium Copper material, which is non-sparking and non-magnetic.

3. Setup and Preparation

Before using the WEDO Hexagonal Non-Sparking Chisel, ensure the following:

- Inspection: Visually inspect the chisel for any signs of wear, cracks, or deformation. The striking end should be free from flash or broken edges.

- Workpiece Security: Secure the workpiece firmly to prevent movement during chiseling.

- Environment Check: Confirm that the working environment is suitable for non-sparking tools, especially in areas with potentially flammable gases or dust.

4. Operating Instructions

The chisel is designed for cutting metal wire or similar materials by hammer striking. Follow these steps for effective and safe operation:

- Positioning: Place the cutting edge of the chisel firmly against the material to be cut.

- Striking: Use a suitable hammer to strike the striking end of the chisel. Apply consistent and controlled force.

- Angle: Maintain an appropriate angle for the chisel to effectively cut or shape the material without excessive force or slippage.

- Repetitive Strikes: For thicker materials, multiple strikes may be necessary. Reposition the chisel as needed.

Figure 3: The chisel is used for hammering to cut metal wire. Its improved striking end prevents flashing and chipping.

5. Maintenance

Proper maintenance ensures the longevity and performance of your WEDO Non-Sparking Chisel:

- Cleaning: After each use, clean the chisel to remove any debris, dust, or residue. Use a dry cloth or a soft brush.

- Storage: Store the chisel in a clean, dry environment. Avoid exposure to extreme temperatures or corrosive chemicals.

- Inspection: Periodically inspect the chisel for any signs of wear or damage. While the material is wear-resistant, regular checks are recommended.

- Sharpening: If the cutting edge becomes dull over time, it can be carefully sharpened by a professional to maintain its effectiveness.

Figure 4: The chisel exhibits high hardness, durability, and good toughness, contributing to its long lifespan.

6. Troubleshooting

This section addresses common issues and their solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Chisel not cutting effectively. | Dull cutting edge; incorrect angle; insufficient force. | Have the edge professionally sharpened; adjust the angle of attack; apply more controlled force. |

| Chisel slipping during use. | Workpiece not secured; improper grip; oily surface. | Ensure workpiece is firmly clamped; maintain a firm grip; clean any oil or grease from the chisel and workpiece. |

| Excessive wear on striking end. | Improper hammer use; striking end not cleaned. | Use a hammer of appropriate weight and material; ensure striking end is clean before use. |

7. Specifications

Detailed specifications for the WEDO Hexagonal Non-Sparking Chisel:

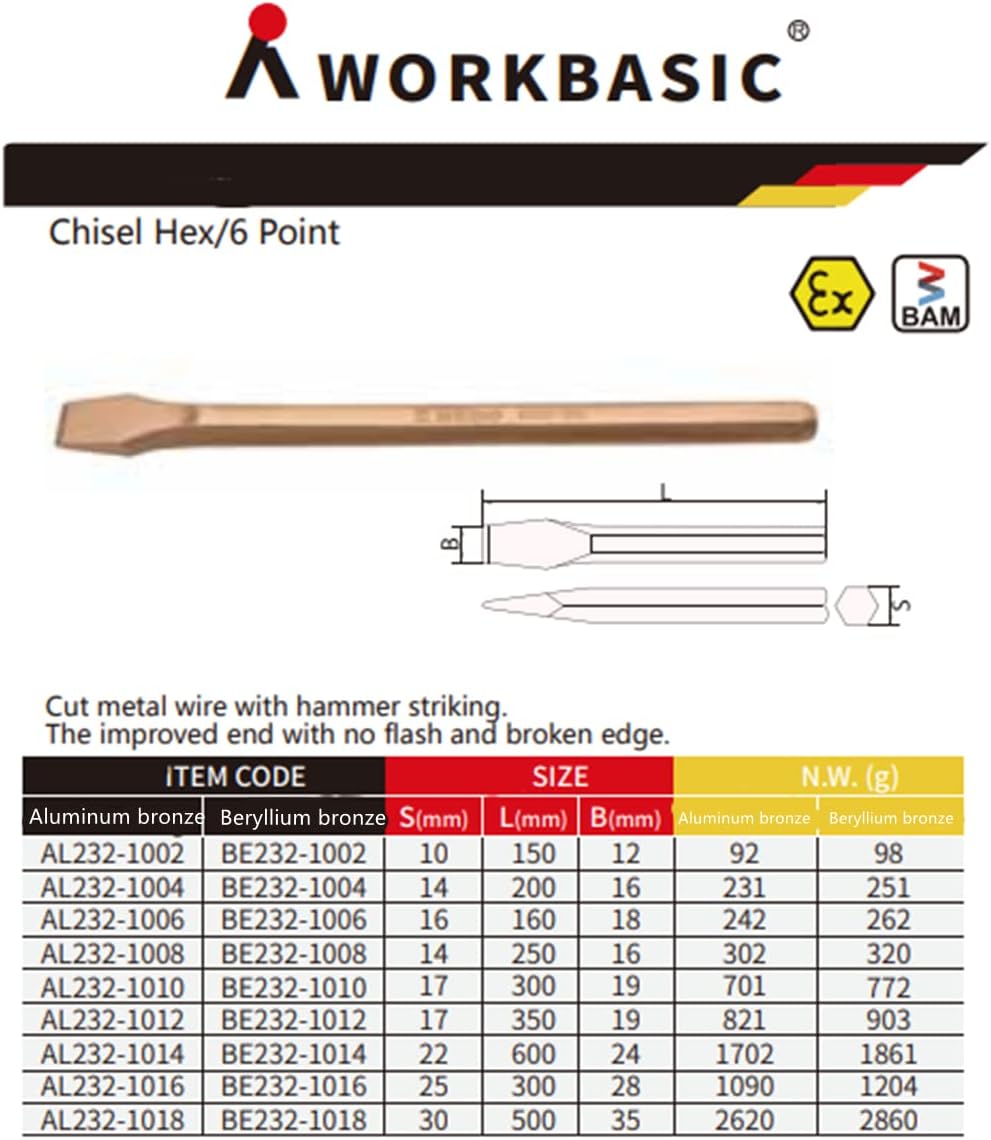

Figure 5: Detailed dimensions and weights for various WEDO Hex/6 Point Chisels, including Beryllium Copper models.

| Attribute | Value |

|---|---|

| Model Number | BE232-1018 |

| Material | Beryllium Copper |

| Size (L x W x H) | 500mm x 35mm x 30mm (approximate, based on 30x35x500mm) |

| Weight | 2860 Grams (2.86 kg) |

| Hardness | 30-40 HRC |

| Blade Edge | Straight |

| Special Features | Non-sparking, Non-magnetic, Wear-resistant |

| Standard Compliance | DIN Standard, BAM and FM Certified, GB Ex ⅡC |

8. Application Areas

The WEDO Hexagonal Non-Sparking Chisel is widely used in industries where safety against sparks and magnetic interference is paramount. These include, but are not limited to:

- Petrochemical industry

- Oil and gas production

- Oil and gas pipelines

- Power generation facilities

- Mining (especially in plastic mining)

- Chemical fiber production

- Other industries with flammable or explosive atmospheres

9. Warranty and Support

WEDO Tools is committed to providing high-quality products and excellent customer service. Our tools are designed with a user-friendly concept and undergo continuous improvement.

For any inquiries, technical support, or warranty claims, please contact WEDO customer service. WEDO has established service centers in various countries, including Germany, Russia, South Korea, Singapore, Canada, the United States, and the United Arab Emirates, to provide timely after-sales service.

For specific warranty details, please refer to the warranty card included with your product or visit the official WEDO Tools website.