1. Product Overview

The HIWIN QEW20CC Linear Guideway is a precision component designed for applications requiring high accuracy, low maintenance, and long-life linear motion. This guideway features a four-row circular-arc contact design with SynchMotion™ Technology, ensuring smooth movement, superior lubrication, quieter operation, and extended running life.

The specific configuration of this model is QEW-20-CC-Z0-C, which denotes:

- Series: QE Series

- Block Type: W (Flange Type)

- Model Size: 20

- Load Type: C (Heavy Load)

- Block Mounting: C (Mounting from Top or Bottom)

- Preload Code: Z0 (Light Preload)

- Precision Code: C (Standard)

Key Features:

- Four-row circular-arc contact: Ensures smooth movement and superior lubrication.

- SynchMotion™ Technology: Contributes to quieter operation and longer running life.

- Broad industrial applicability: Interchangeable with the HIWIN-EG series, suitable for high-speed, low-noise, and reduced dust generation environments.

- Smooth linear motion: Achieves high accuracy and rigidity when mounted on a surface meeting installation requirements.

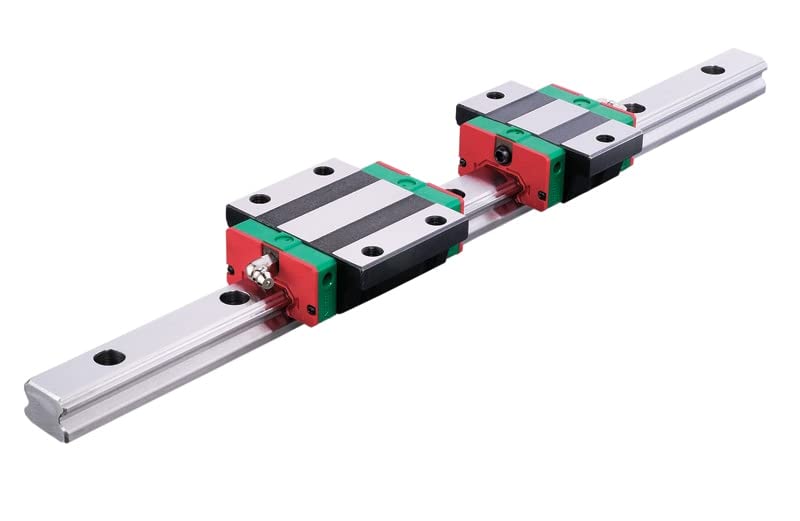

Figure 1: HIWIN QEW20CC Linear Guideway system, showing two linear blocks mounted on a rail.

Video 1: An official overview of HIWIN Linear Guideways, demonstrating their application and key features in various industrial settings.

2. Setup and Installation

Proper installation is crucial for the optimal performance and longevity of your HIWIN QEW20CC Linear Guideway. Ensure all mounting surfaces are clean, flat, and free from burrs or debris.

2.1. Preparation

- Unpacking: Carefully remove the guideway from its packaging. Avoid dropping or subjecting it to impact.

- Cleaning: Gently wipe any protective oil or grease from the mounting surfaces of the guideway and the machine bed using a clean, lint-free cloth and a suitable solvent (e.g., isopropyl alcohol).

- Inspection: Visually inspect the guideway for any signs of damage during transit.

2.2. Mounting the Rail

- Align the linear rail with the pre-drilled mounting holes on your machine bed.

- Insert the mounting bolts into the rail holes.

- Lightly tighten the bolts in a sequential pattern (e.g., from the center outwards) to ensure even pressure. Do not fully tighten yet.

- Use a precision straight edge or dial indicator to verify the straightness and parallelism of the rail. Adjust as necessary.

- Once alignment is confirmed, gradually tighten all mounting bolts to the recommended torque specifications (refer to your machine's manual or HIWIN's detailed installation guide for specific torque values).

2.3. Mounting the Block

The QEW20CC block is designed for mounting from either the top or bottom.

- Carefully slide the linear block onto the rail. Ensure it moves smoothly without excessive force.

- Align the block with the mounting holes on your moving platform or component.

- Insert and lightly tighten the mounting bolts for the block.

- Verify the alignment of the moving platform relative to the rail.

- Gradually tighten the block mounting bolts to the recommended torque specifications.

Figure 2: Top view of the HIWIN QEW20CC linear guideway block, showing mounting points.

3. Operation

The HIWIN QEW20CC Linear Guideway is designed for smooth and precise linear motion. Once properly installed, its operation is largely passive, facilitating the movement of attached components.

3.1. Basic Functionality

- The linear block moves along the linear rail, guided by recirculating balls within the block.

- The design minimizes friction, allowing for high-speed and high-precision movement with minimal effort.

- The preload (Z0 - Light Preload) ensures a balance between rigidity and smooth motion, suitable for applications where moderate precision and low friction are desired.

- The heavy load capacity (C) allows the guideway to support substantial weights while maintaining performance.

Ensure that the operating environment is kept as clean as possible to prevent contaminants from entering the block's internal mechanisms, which could affect performance and lifespan.

4. Maintenance

Regular maintenance is essential to preserve the accuracy, extend the lifespan, and ensure the reliable operation of your HIWIN QEW20CC Linear Guideway.

4.1. Lubrication

Proper lubrication is critical for linear guideways. The QEW20CC block is equipped with lubrication points for easy application.

- Frequency: Lubrication frequency depends on operating conditions (speed, load, environment). As a general guideline, inspect lubrication every 100-200 operating hours or monthly.

- Lubricant Type: Use high-quality lithium-based grease or a recommended linear motion guideway lubricant. Consult HIWIN's official documentation for specific recommendations.

- Application: Apply grease through the designated grease nipple on the linear block using a grease gun until a small amount of fresh grease appears at the seals.

- Oil Lubrication: For oil-lubricated systems, ensure a continuous supply of the recommended lubricating oil.

4.2. Cleaning

- Regularly clean the exterior surfaces of the linear rail and block to remove dust, chips, and other contaminants.

- Use a clean, lint-free cloth. For stubborn grime, a mild, non-corrosive cleaning agent can be used, ensuring it does not damage seals or painted surfaces.

- Pay particular attention to the rail's raceway surfaces and the block's end seals.

4.3. Inspection

- Periodically check for any signs of wear, corrosion, or damage on the rail and block.

- Verify that all mounting bolts are securely tightened.

- Listen for unusual noises during operation, which could indicate a lack of lubrication or internal damage.

- Check for any excessive play or looseness in the linear motion.

5. Troubleshooting

This section addresses common issues that may arise during the operation of your HIWIN QEW20CC Linear Guideway.

5.1. Common Issues and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Rough or Stiff Movement | Lack of lubrication Contamination (dust, chips) Misalignment of rail or block Over-tightened mounting bolts | Apply appropriate lubricant Clean rail and block surfaces Re-align rail/block; check mounting surface flatness Loosen and re-tighten bolts to correct torque |

| Excessive Noise | Insufficient lubrication Contamination Internal damage to block | Lubricate thoroughly Clean guideway Inspect for damage; consider replacement if severe |

| Reduced Accuracy | Rail or block misalignment Wear or damage to raceways Loose mounting bolts | Check and correct alignment Inspect for wear; replace if necessary Tighten all mounting bolts to specifications |

| Corrosion/Rust | Exposure to moisture or corrosive substances Inadequate protective coating/lubrication | Ensure proper sealing of environment Apply rust preventative or appropriate lubricant; clean affected areas |

If issues persist after attempting these solutions, it is recommended to consult a qualified technician or contact HIWIN technical support.

6. Specifications

Detailed specifications for the HIWIN QEW20CC Linear Guideway:

| Attribute | Value |

|---|---|

| Model Number | QEW20CC |

| Series | QE Series |

| Block Type | W (Flange Type) |

| Model Size | 20 |

| Load Type | C (Heavy Load) |

| Block Mounting | C (Mounting from Top or Bottom) |

| Preload Code | Z0 (Light Preload) |

| Precision Code | C (Standard) |

| Product Dimensions | 3.78 x 2.67 x 1.48 inches |

| Item Weight | 12.06 Ounces |

| Material | Carbon Steel |

| Manufacturer | HIWIN |

| Country of Origin | Taiwan |

7. Warranty and Support

For specific warranty information regarding your HIWIN QEW20CC Linear Guideway, please refer to the warranty card included with your product or visit the official HIWIN website. Warranty terms typically cover manufacturing defects under normal operating conditions.

For technical support, service, or further inquiries, please contact your authorized HIWIN distributor or the manufacturer directly. Ensure you have your product model number (QEW20CC) and any relevant purchase details ready when seeking support.

Manufacturer: HIWIN

Seller: Delta Sigma Automation