1. Product Overview

The Makerbase MKS Monster8 V2 is a 32-bit control board designed for advanced 3D printers, offering extensive features and compatibility. It is suitable for large 3D printers such as Voron 2.4 and Creality Ender-3 series (Ender-3, Ender-3 V2, Ender-3 Pro).

Key Features:

- 8 Stepper Drivers: Supports multiple motor drives including A4988, DRV8825, LV8729, TMC2208, TMC2209, TMC2225, TMC2226.

- 9 Motor Interfaces: Driver0, 1, 2-1, 2-2, 3, 4, 5, 6, 7 for flexible configurations.

- Firmware Support: Compatible with Marlin 2.0.x and Klipper (requires a Klipper host like Raspberry Pi or MKS PI).

- Display Compatibility: Supports LCD2004, LCD12864, MKS MINI12864 V1.0/V3.0, and MKS touchscreens (MKS TFT24, MKS TFT28, MKS TFT32, MKS TFT35, MKS H43).

- Expansion Functions: 6 endstops with power select (X-, X+, Y-, Y+, Z-, Z+), 3D TOUCH (PA8) interface, DFU mode via Boot0 button, driver power select (5V or 3.3V), TMC UART and SPI mode, SENSORLESS_HOMING (Diag0-5), integrated SPI communication micro SD card, reserved SPI signal UDISK, and virtual USB device.

- MCU: STM32F407VET6, 168MHz, 512KB flash, 192KB RAM, built-in CAN transceiver and interface.

- Power Input: DC12-24V.

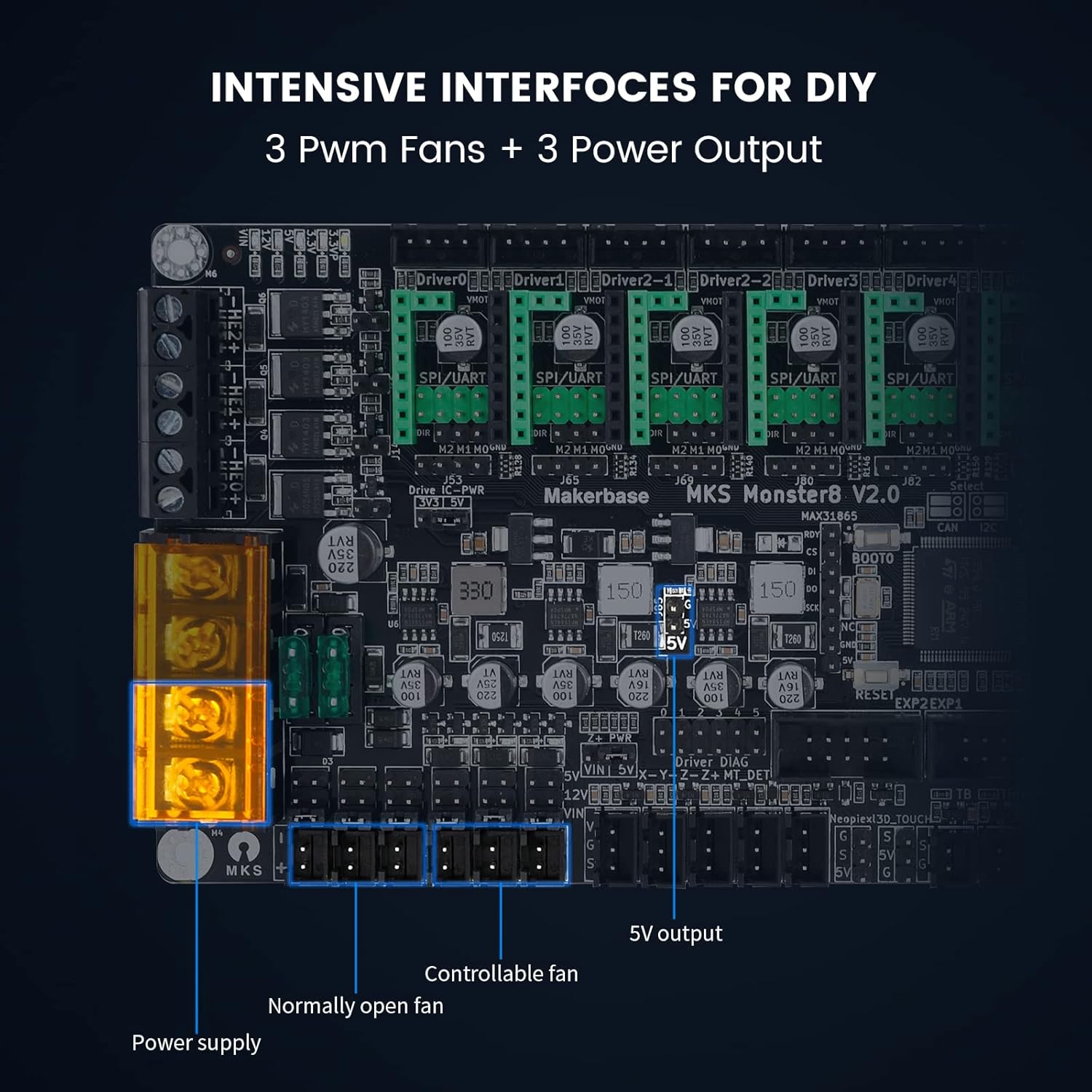

- Power Output: 2 MP1584EN outputs (DC12V for fans and DC5V), 3 PWM fans + 3 power outputs (selectable VIN, DC12V, DC5V).

- Protection: TVS power spike processing, 4KB EEPROM on board.

- Connectivity: Type-C online serial port.

2. Setup Guide

2.1 Driver Installation

Before connecting any components, ensure the motor drivers are correctly installed. For Dir/Step mode, insert the jumper cap into the pins marked with a red box in the diagram. The video below demonstrates using the TMC2209 driver in Dir/Step mode as an example.

2.2 Wiring Connections

Carefully follow the wiring diagram and instructions to connect all components. Pay close attention to positive and negative poles for power connections.

- Power Supply: Connect the main power supply (+POWER+ 12/24V).

- Heated Bed: Connect the heated bed, paying attention to the positive and negative poles (+HBED-).

- Hotend: Connect the hotend (-HE0+).

- Fans: Connect the always-on fan and controllable fan.

- Thermistors: Connect the hotend thermistor (TH0) and heated bed thermistor (TB).

- Endstops: Connect the X-axis endstop (X-), Y-axis endstop (Y-), and Z-axis endstop (Z-).

- Motors: Connect the X-axis motor (Driver0), Y-axis motor (Driver1), Z-axis motor (Driver2-1), and Extruder motor (Driver3).

- Display: Connect the MKS TS35 touchscreen display to EXP1 and EXP2 using DuPont wires.

2.3 Firmware Configuration (Marlin)

To ensure proper functionality, the Marlin firmware needs to be configured for the MKS Monster8 V2 board. Refer to the official Makerbase GitHub for the latest firmware and detailed instructions. Key configuration steps include:

- Set the mainboard name to

BOARD_MKS_MONSTER8inConfiguration.h. - Set

SERIAL_PORTto-1. - Set the user interface to

TFT_COLOR_UI. - Enable

SDSUPPORT. - Enable

SDCARD_CONNECTION_ONBOARDinpins_MKS_MONSTER8.h. - Enable

EEPROM_SETTINGSandEEPROM_CHITCHAT. - Set

default_envs = mks_monster8inplatformio.ini. - Set

EXTRUDERSto 1. - Set

TEMP_SENSOR_0andTEMP_SENSOR_BEDto 1. - Enable

USE_XMIN_PLUG,USE_YMIN_PLUG,USE_ZMIN_PLUG. - Set

X(Y,Z)_MIN_ENDSTOP_INVERTINGtotrue. - Set

X(Y,Z)_HOME_DIRto-1. - Set

X(Y)_BED_SIZEto200andZ_BED_SIZEto250. - Set

X_DRIVER_TYPEtoTMC2209(adjust for other drivers as needed). - Set

INVERT_X(Y,E0)_DIRtofalseandINVERT_Z_DIRtotrue. - Enable

MESH_BED_LEVELINGandLCD_BED_LEVELING.

For detailed firmware configuration, please visit the official Makerbase GitHub repository: https://github.com/makerbase-mks/MKS-Monster8

2.4 Firmware Update

After compiling the firmware, copy the "asset" folder and the .bin file generated after compilation to the root directory of the SD card. Insert the SD card into the mainboard's slot, then turn on the power to update the firmware. The display will show the update progress.

3. Operating Instructions

Once the MKS Monster8 V2 board is installed and firmware updated, you can operate your 3D printer using the connected display. The display allows for control over various printer functions.

3.1 Basic Movement and Controls

Use the touchscreen or rotary encoder on your MKS display to navigate menus and control printer axes (X, Y, Z) and the extruder. This allows for manual positioning and filament loading/unloading.

3.2 Initiating a Print

After preparing your G-code file on an SD card, insert it into the display's SD card slot (if applicable) or the mainboard's slot. Navigate to the print menu on the display and select your file to begin printing. Ensure the heated bed and hotend reach the desired temperatures before printing starts.

4. Maintenance

Regular maintenance ensures the longevity and optimal performance of your MKS Monster8 V2 control board.

- Keep Clean: Regularly clean the board and surrounding area to prevent dust and debris accumulation, which can lead to overheating or short circuits.

- Avoid Moisture: Ensure the control board is kept in a dry environment to prevent damage from moisture or humidity.

- Check Connections: Periodically inspect all wiring connections to ensure they are secure and free from wear or damage. Loose connections can cause intermittent issues or component failure.

- Firmware Updates: Stay updated with the latest firmware releases from Makerbase to benefit from bug fixes, performance improvements, and new features.

5. Troubleshooting

This section addresses common issues and their solutions for the MKS Monster8 V2 control board.

5.1 Power-Related Issues

- Board Not Powering On: If the board does not power on, first check if the power supply wiring is reversed. The MKS Monster8 V2 includes TVS power supply anti-reverse and spike protection, preventing damage from incorrect polarity, but the board will not function until correctly wired.

- Raspberry Pi "Currently Throttled" Error: The MKS Monster8 V2 provides a stable DC 5.1V/3A power output specifically designed for Raspberry Pi. If you encounter a "Currently Throttled" error, ensure your Raspberry Pi is connected to this dedicated power interface on the Monster8 V2 to avoid voltage and current instability.

5.2 Motor and Sensor Protection

- Stepper Motor Damage: The board features a protection circuit for back electromotive force (EMF) generated by stepper motors. This significantly reduces potential damage to motor drivers, even if the print head is manually moved or obstructed.

- ESD Damage: The motherboard's MOS drive circuit and temperature measurement circuit are protected by Schottky diodes, reducing damage from external static electricity spikes. The board has been tested to withstand 4kV of static electricity.

- PL08N Leveling Sensor Issues: The PL08N leveling sensor signal interface is protected by Schottky diodes with a withstand voltage of 40V. This ensures that the signal pin of the chip will not be burned out due to sensor-related issues.

6. Specifications

| Feature | Detail |

|---|---|

| Manufacturer | Makerbase Motherboard Monster8 |

| Package Dimensions | 8.03 x 5.12 x 3.11 inches |

| Item Weight | 9.1 ounces |

| ASIN | B09M3WKJS4 |

| Item Model Number | MKS-MONSTER8 |

| Batteries Required | No |

| Included Components | PCBA |

| Color | Black |

| Brand | Makerbase |

| Voltage | 24 Volts (DC) |

| Display Type | LCD or Touchscreen |

| MCU | STM32F407VET6, 168MHz, 512KB Flash, 192KB RAM |

| Stepper Drivers | 8 (supports A4988, DRV8825, LV8729, TMC2208, TMC2209, TMC2225, TMC2226) |

| Firmware | Marlin 2.0.x, Klipper |

| Power Protection | TVS power spike processing, pluggable fuse |

| Raspberry Pi Power Output | DC5.1V/3A |

7. Support and Resources

For further assistance, firmware updates, and community support, please refer to the following official Makerbase resources:

- Official GitHub Repository: https://github.com/makerbase-mks/MKS-Monster8 (for firmware and technical documentation)

- YouTube Channel: https://www.youtube.com/@makerbaseteam4217 (for video tutorials and guides)

- Facebook Page: https://www.facebook.com/Makerbase.mks/ (for community interaction and updates)