Introduction

The JUKI DDL-8700-7 Single Needle Drop Feed Automatic Industrial Sewing Machine is designed for efficient and high-quality sewing. It comes complete with a table, legs, servo motor, and LED lamp. This machine features mechanisms optimized for low-tension sewing, allowing it to handle various materials and consistently produce beautiful, uniform seams.

This manual provides essential information for the setup, operation, maintenance, and troubleshooting of your Juki DDL-8700-7 sewing machine.

Setup and Assembly

Your Juki DDL-8700-7 machine is designed for quick setup as it arrives largely pre-assembled. Follow these steps to prepare your machine for operation:

- Unpacking and Placement: Carefully unpack all components. The machine, table, stand, 110V motor, and drawer are included. Place the assembled table and stand in your desired workspace.

- Machine Mounting: The machine head is already mounted to pin hinges in the stand. Ensure it is securely seated.

- Oil Pan Installation: The oil pan should be pre-installed. Verify its correct position and ensure it is clean.

- Belt Tension Adjustment: The belt tension is pre-adjusted. Do not alter unless necessary and refer to a qualified technician.

- Belt Guard Installation: The belt guard is pre-installed for safety.

- Lubrication: Pour the recommended JUKI MACHINE OIL 7 (or equivalent ISO VG7) into the designated oil reservoir. Refer to the machine's oil level indicator.

- Thread Stand Setup: Assemble and set up the thread stand according to the included instructions. This typically involves attaching the vertical rod and thread guides.

- Power Connection: Connect the machine to a standard 110V power outlet. The machine is ready to plug in directly.

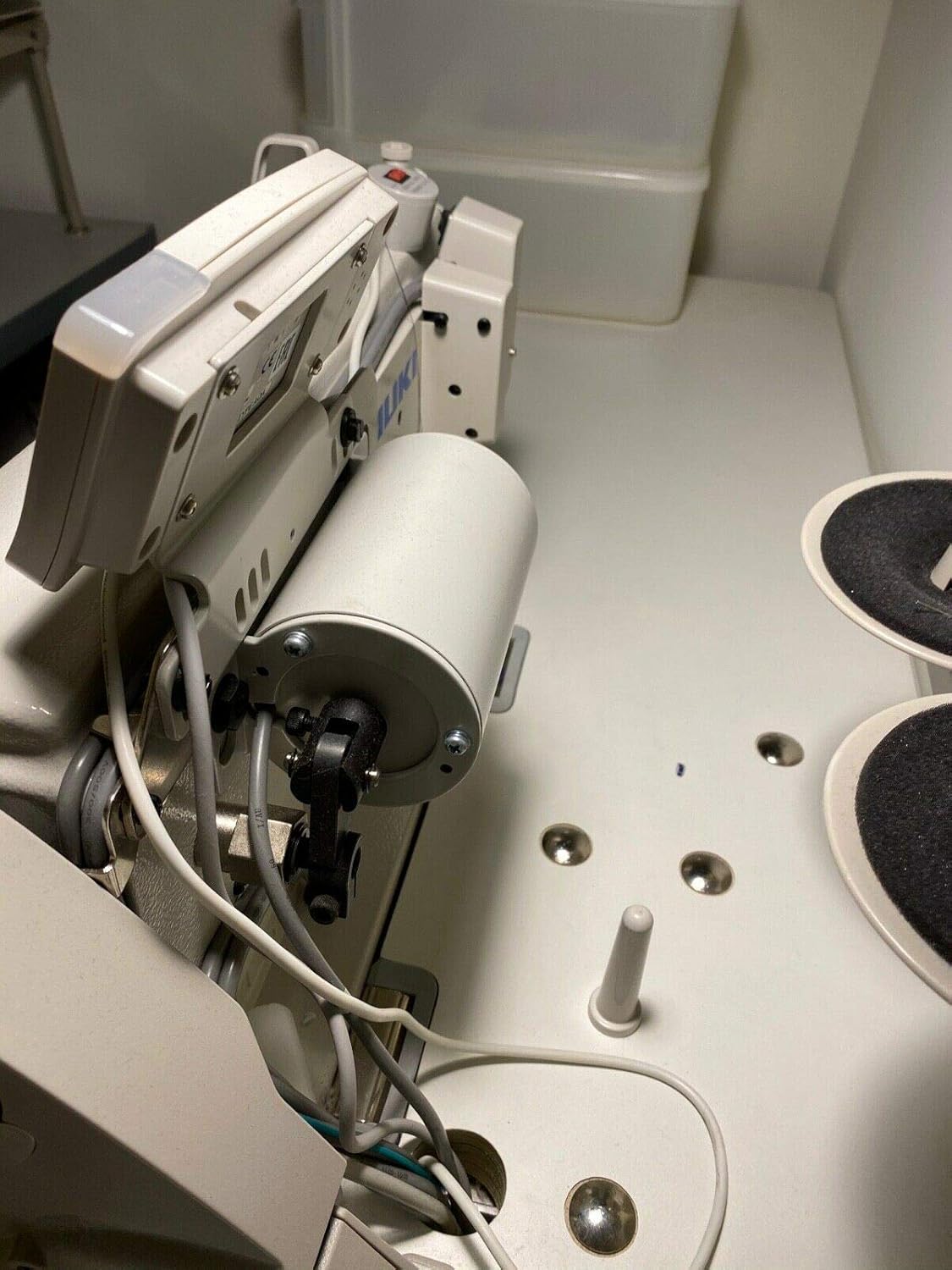

Figure 1: Fully assembled Juki DDL-8700-7 machine with table and stand.

Figure 2: View of the servo motor installed beneath the machine table.

Operating Instructions

The Juki DDL-8700-7 is equipped with a highly efficient servo motor and an advanced control panel for precise operation.

Servo Motor Advantages

- Energy Efficiency: Uses up to 90% less power compared to traditional clutch motors.

- Lightweight Design: Approximately 1/3 lighter than clutch motors.

- Reverse Rotation: Motor rotation can be reversed with a simple flick of a switch.

- Durability: Fewer wear-and-tear parts, reducing maintenance needs.

- Consistent Speed: Maintains configured speed regardless of foot pedal pressure.

Control Panel (CP-18 / SC-920C)

The SC-920C control box, paired with the M92 servomotor, offers robust and energy-efficient control. It is designed to be resistant to voltage fluctuations, noise, and vibration.

- Energy-Saving Mode: The SC-920C features an energy-saving mode that reduces power consumption by approximately 25% during standby (when the motor is not rotating) compared to previous models.

- Automatic Reverse Feed: This function is provided as standard, allowing for easy back-tacking at the start and end of seams.

Figure 3: The CP-18 control panel for machine settings.

Basic Sewing Operation

- Threading: Follow the threading path indicated on the machine. Ensure the thread is correctly seated in all guides and tension discs.

- Needle Selection: Use DB X 1 needles, suitable for sizes 9-18, depending on your fabric and thread.

- Bobbin Winding and Insertion: Wind the bobbin evenly and insert it into the automatic-lubricating full-rotary hook mechanism.

- Stitch Length Adjustment: Adjust the stitch length using the dial on the machine head. The maximum stitch length is 4mm.

- Presser Foot Lift: The presser foot can be lifted by hand (up to 5.5 mm) or by knee lever (up to 13 mm) for easy fabric placement.

- Starting to Sew: Place your fabric under the presser foot. Lower the presser foot. Gently press the foot pedal to begin sewing. The machine will maintain the configured speed.

- Reverse Stitching: Utilize the automatic reverse feed function for securing stitches at the beginning and end of seams.

Figure 4: Detailed view of the needle, presser foot, and feed dog area.

Figure 5: Top view of the Juki DDL-8700-7 machine head, showing the thread path and controls.

Maintenance

Regular maintenance ensures the longevity and optimal performance of your Juki DDL-8700-7 sewing machine.

- Lubrication: The machine features automatic lubrication. Regularly check the oil level in the reservoir and replenish with JUKI MACHINE OIL 7 (equivalent to ISO VG7) as needed. Ensure the oil is clean and free of debris.

- Cleaning:

- Periodically clean lint and dust from the bobbin case area, feed dog, and under the needle plate using a small brush or vacuum.

- Wipe down the exterior of the machine with a soft, dry cloth.

- Needle Replacement: Replace needles regularly, especially when sewing different materials or if you notice skipped stitches or fabric damage.

- Professional Servicing: For complex issues or annual tune-ups, it is recommended to have the machine serviced by a qualified industrial sewing machine technician.

Troubleshooting

This section addresses common issues you might encounter with your Juki DDL-8700-7. For more detailed troubleshooting, please refer to the comprehensive service manual or contact customer support.

| Problem | Possible Cause | Solution |

|---|---|---|

| Skipped Stitches | Incorrect needle insertion, bent or dull needle, improper threading, incorrect needle size for fabric. | Re-insert needle correctly, replace needle, re-thread machine, use appropriate needle size. |

| Thread Breakage | Incorrect tension, poor quality thread, burrs on needle plate or hook, incorrect threading. | Adjust tension, use quality thread, check for burrs and smooth them, re-thread machine. |

| Uneven Stitches | Inconsistent fabric feeding, tension issues, worn feed dog. | Ensure even fabric feeding, adjust tension, clean feed dog, consider professional inspection. |

| Machine Not Starting | Power cord not connected, emergency stop engaged, motor issue. | Check power connection, disengage emergency stop, contact technician if motor is unresponsive. |

Always unplug the machine from the power source before performing any inspection or maintenance.

Specifications

| Feature | Detail |

|---|---|

| Model Number | DDL 8700-7 |

| Brand | iKonix |

| Application | Medium-Weight Materials |

| Max. Sewing Speed | 5000 Stitches per Minute |

| Max. Stitch Length | 4mm |

| Needle Bar Stroke | 30.7mm |

| Lift of Presser Foot (Hand) | 5.5 mm |

| Lift of Presser Foot (Knee) | 13 mm |

| Needle Type | DB X 1, sizes 9-18 |

| Feed Dog | 4-row |

| Hook Type | Automatic-lubricating full-rotary hook |

| Lubrication | Automatic |

| Lubricating Oil | JUKI MACHINE OIL 7 (equivalent to ISO VG7) |

| Control Box | SC-920C (Compact-size servomotor M92, 450W) |

| Machine Motor | Single-phase 100~240V, 3-phase 200~240V |

| Power Requirement | Single-phase 100~240V, 3-phase 200~240V |

| Power Consumption | 320VA |

| Unit Dimensions (LxWxH) | 48 inches x 20 inches x 48 inches |

| Item Weight | 229 pounds |

| UPC | 880336697903 |

Warranty and Support

For specific warranty details, please refer to the documentation provided at the time of purchase or contact the seller directly. Warranty terms typically cover manufacturing defects for a specified period.

For technical support, parts, or service inquiries, please contact your authorized iKonix dealer or the point of purchase. Ensure you have your model number (DDL 8700-7) and purchase date available when seeking support.

While protection plans may be available for purchase separately, these are distinct from the manufacturer's warranty.