1. Product Overview

The DB Electrical 410-48316 Starter is a high-quality aftermarket component designed to meet or exceed OEM specifications for various Mitsubishi Industrial and Caterpillar models. This starter is engineered for reliable engine ignition and long service life.

Key features include:

- Unit Type: Starter

- Voltage: 24V

- Rotation: Clockwise (CW)

- Teeth: 10

- KW: 5.0

- Starter Type: OSGR

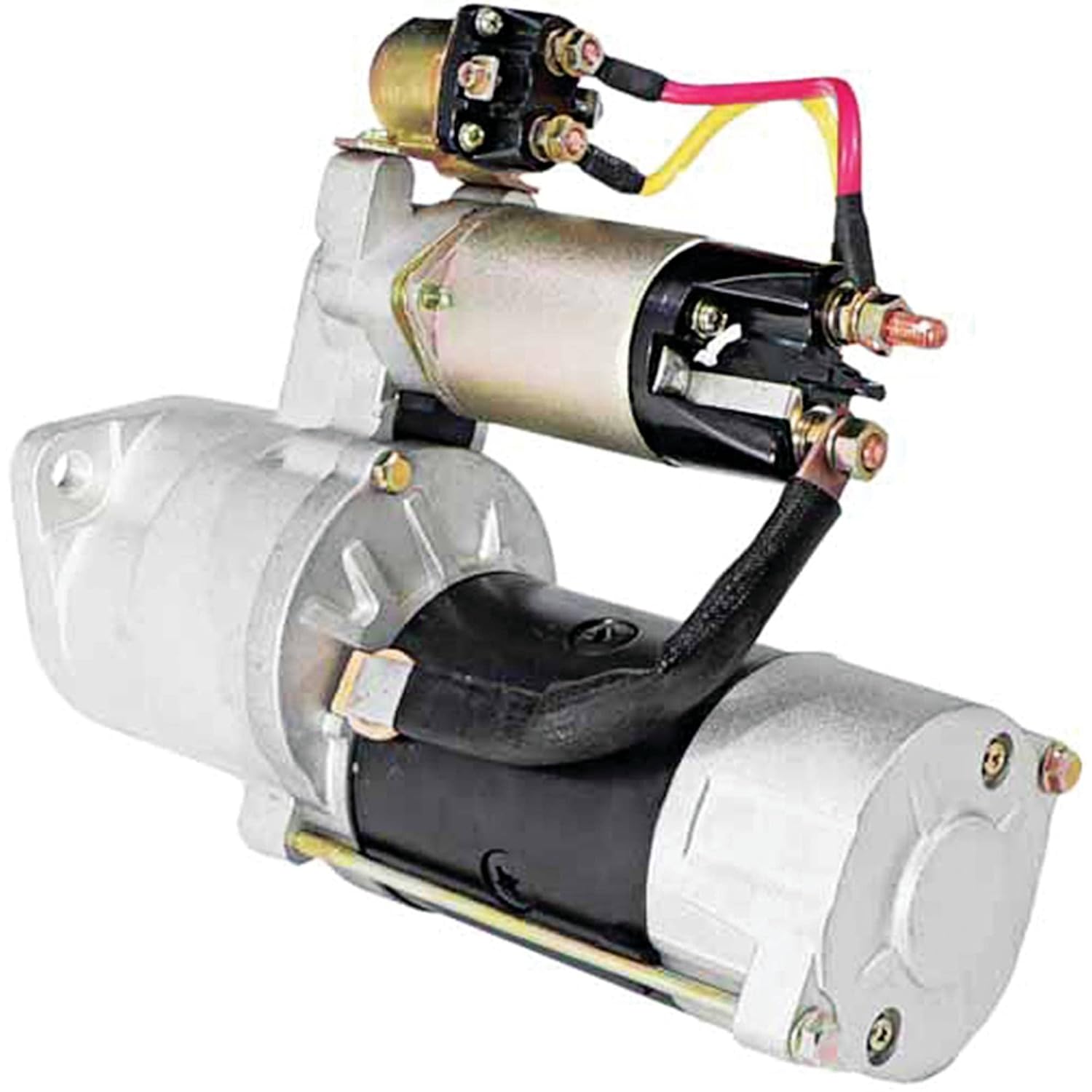

Figure 1.1: Front view of the DB Electrical 410-48316 Starter, showing the solenoid and gear assembly.

Figure 1.2: Side view of the DB Electrical 410-48316 Starter, highlighting the electrical connections.

Figure 1.3: Angled view of the DB Electrical 410-48316 Starter, showing the mounting points.

Figure 1.4: Rear view of the DB Electrical 410-48316 Starter, displaying the motor housing.

2. Technical Specifications

| Specification | Value |

|---|---|

| Unit Type | Starter |

| Voltage | 24 Volts |

| Rotation | CW (Clockwise) |

| Teeth | 10 |

| KW | 5.0 |

| Starter Type | OSGR |

| Product Dimensions | 14.7 x 9 x 6 inches |

| Item Weight | 20 Pounds |

| Amperage | 20 Amps |

This starter is compatible with/replacement for various models, including:

- CATERPILLAR: DP40

- MITSUBISHI: FD-20, FD-20B-D, FD-20B-DS, FD-20D, FD-25, FD-25B-D, FD-25B-DS, FD-25D, FD-25DS, FD-25T, FD-30, FD-30B-D, FD-30B-DS, FD-30D, FD-30DS, FD-30T, FD-35A, FD-35A-D, FD-35AB-D, FD-35AT, FD-35D, FD-35D2, FD-35DS, FD-38, FD-40D, FD-40D2, FD-45D, FD-45D2, FD-50C, FD-50C-D

3. Installation and Setup

Proper installation is crucial for the safe and effective operation of your new starter. If you are unsure about any step, it is recommended to consult a qualified mechanic.

3.1 Safety Precautions

- Always disconnect the vehicle's battery (negative terminal first) before beginning any electrical work.

- Wear appropriate personal protective equipment, including safety glasses and gloves.

- Ensure the vehicle is securely supported on jack stands if working underneath.

- Allow the engine to cool completely before starting work.

3.2 Installation Steps

- Locate the Starter: Identify the existing starter motor on your vehicle. Its location can vary by vehicle model.

- Disconnect Wiring: Carefully disconnect all electrical connections from the old starter. Note the position of each wire for correct reinstallation.

- Remove Mounting Bolts: Remove the bolts securing the old starter to the engine or transmission housing.

- Remove Old Starter: Carefully extract the old starter motor from its position. It may be heavy.

- Install New Starter: Position the new DB Electrical 410-48316 Starter in place and secure it with the mounting bolts. Ensure it is seated correctly.

- Reconnect Wiring: Reconnect all electrical wires to the new starter, ensuring all connections are tight and secure. Refer to your vehicle's service manual for specific wiring diagrams if needed.

- Reconnect Battery: Reconnect the vehicle's battery (positive terminal first, then negative).

- Test Operation: Attempt to start the engine to verify proper installation and function.

4. Operating Instructions

The DB Electrical 410-48316 Starter operates as an integral part of your vehicle's starting system. Its function is to crank the engine to initiate combustion.

4.1 Normal Operation

- Ensure the vehicle's transmission is in Park (P) or Neutral (N).

- Insert the ignition key and turn it to the 'START' position.

- The starter motor will engage the engine's flywheel, causing the engine to crank.

- Once the engine starts, release the key, and the starter will disengage.

4.2 Important Considerations

- Avoid prolonged cranking (more than 10-15 seconds) to prevent overheating the starter motor. If the engine does not start, wait a few minutes before attempting again.

- Do not attempt to start the engine if it is already running.

5. Maintenance

The DB Electrical 410-48316 Starter is designed for durability and minimal maintenance. However, periodic checks can help ensure its longevity and optimal performance.

5.1 General Maintenance Tips

- Inspect Connections: Periodically check all electrical connections to the starter motor for tightness and corrosion. Loose or corroded connections can impede current flow and affect performance.

- Keep Clean: Ensure the starter motor and its surrounding area are free from excessive dirt, oil, and debris. A clean environment helps prevent overheating and extends component life.

- Battery Health: A healthy battery is essential for proper starter operation. Ensure your vehicle's battery is fully charged and in good condition.

- Cable Integrity: Inspect battery cables and starter cables for any signs of wear, fraying, or damage. Replace damaged cables promptly.

6. Troubleshooting

This section provides guidance for common issues you might encounter with your starter motor. Always ensure safety precautions are followed before attempting any troubleshooting.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Engine does not crank or cranks slowly | Dead or weak battery | Check battery voltage; charge or replace battery. |

| Engine does not crank, but lights/accessories work | Loose or corroded battery/starter connections | Inspect and clean battery terminals and starter connections. Tighten as necessary. |

| Clicking sound when attempting to start | Low battery charge; faulty starter solenoid | Charge battery. If issue persists, inspect starter solenoid for proper function. |

| Starter spins but engine does not crank | Faulty starter drive (bendix) | The starter drive may not be engaging the flywheel. Replacement of the starter may be necessary. |

If these troubleshooting steps do not resolve the issue, it is recommended to seek assistance from a certified automotive technician.

7. Warranty and Support

7.1 Product Warranty

The DB Electrical 410-48316 Starter comes with a 1-year warranty from the date of purchase. This warranty covers defects in materials and workmanship under normal use and service. If the product does not function flawlessly within one year of your order, DB Electrical will replace it.

Please retain your proof of purchase for warranty claims.

7.2 Customer Support

For any questions, technical assistance, or warranty claims, please contact DB Electrical customer support. Our team is dedicated to assisting you with any issues you may encounter.

You can find contact information on the official DB Electrical website or through your original point of purchase.

Video 7.1: An official video from DB Electrical, titled "Starter Motor & Bendix Video 4", providing additional insights into starter motors and bendix components. This video is provided by the seller.