1. Introduction

This manual provides essential instructions for the safe and effective installation, operation, and maintenance of your DALY BMS 4S 12V 200A LiFePO4 Battery Protection Module. This module is designed to optimize the performance and extend the lifespan of LiFePO4 battery packs by providing critical protection functions.

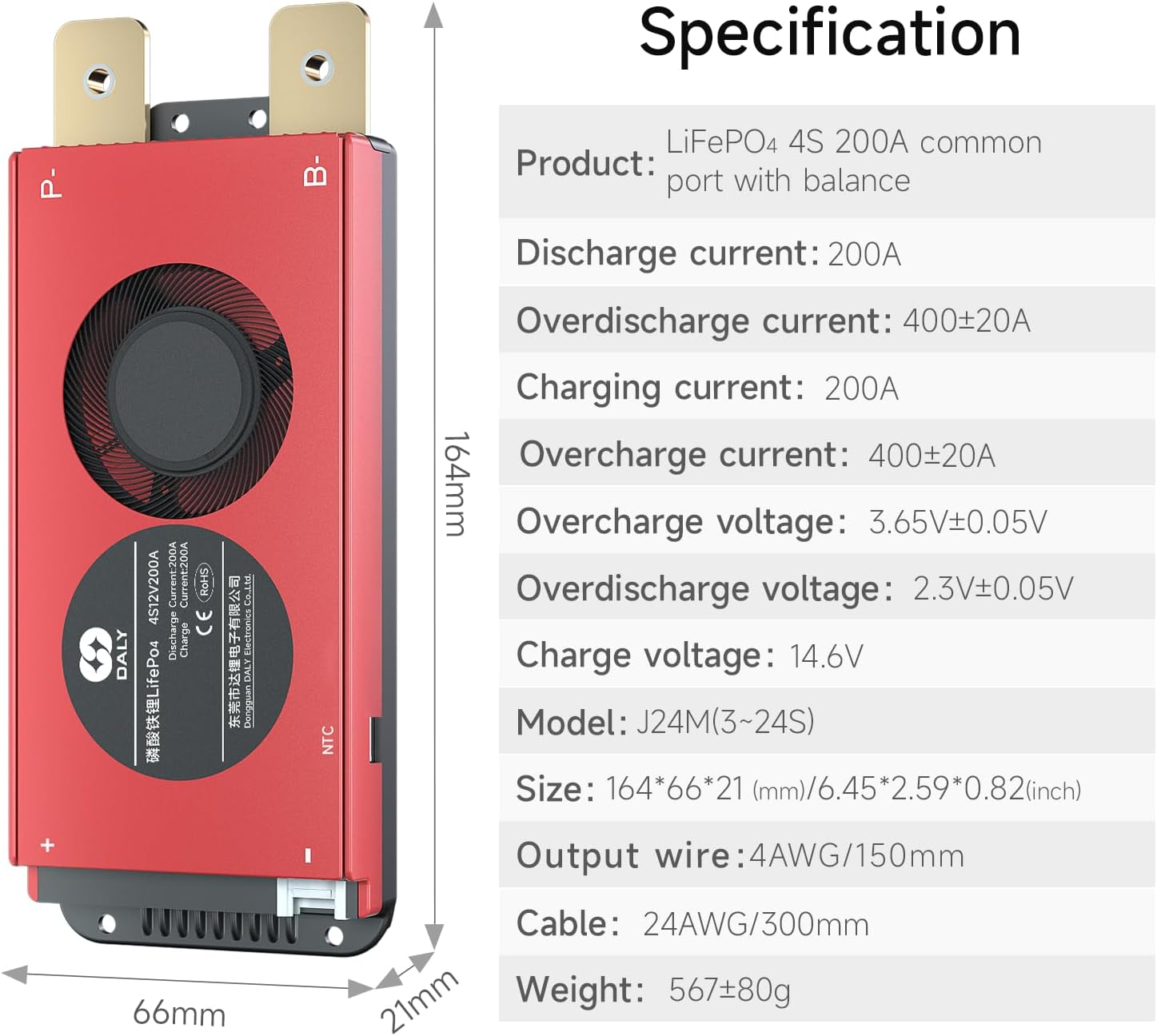

Figure 1: DALY BMS 4S 12V 200A LiFePO4 Battery Protection Module.

The DALY BMS offers comprehensive protection against overcurrent, overcharge, overdischarge, short circuit, and temperature fluctuations. It features double protection through injection patent technology and a patent shell, ensuring waterproof, dustproof, shockproof, and anti-static properties. High-quality components and precise acquisition accuracy contribute to its reliable performance.

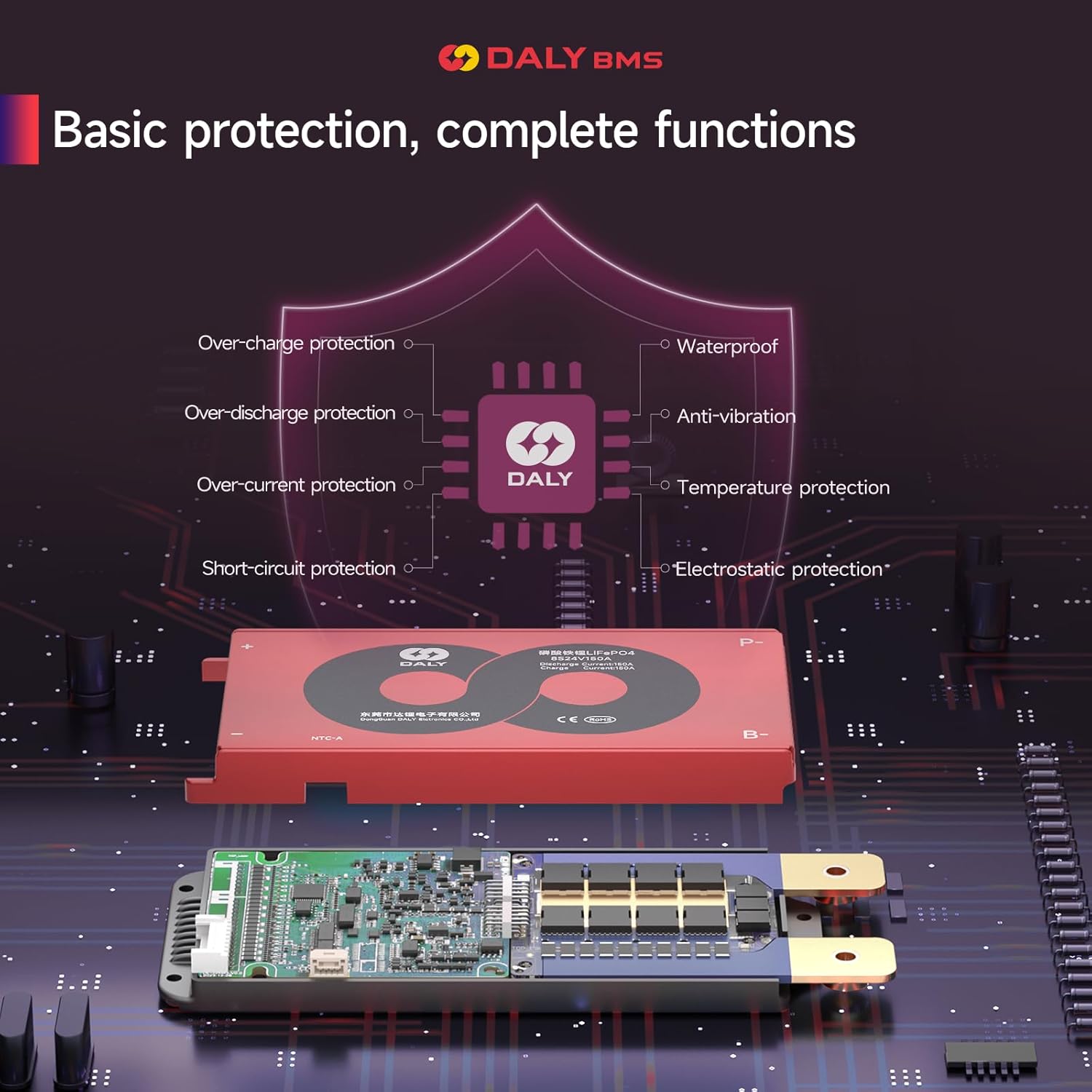

Figure 2: Advanced technology features of the DALY BMS, highlighting its moisture-proof, anti-vibration, anti-oxidation properties, and compact, easy-to-install design.

Product Overview Video

Video 1: An overview of the DALY BMS series, highlighting various models and key features such as shockproof design and MCU-level chip integration. This video provides a general introduction to the product line's capabilities and robust construction.

2. Safety Information

- Always wear appropriate personal protective equipment (PPE) when handling batteries and wiring.

- Ensure all connections are secure and properly insulated to prevent short circuits.

- Verify correct polarity before making any connections. Incorrect polarity can damage the BMS and battery.

- Do not attempt to disassemble or modify the BMS module.

- Keep the BMS away from water, heat, and flammable materials.

- If you are a novice, it is recommended to set the soldering iron temperature to about 350 degrees Celsius. Professional solder temperature is 420 degrees Celsius.

3. Packing List

Figure 3: Contents of the DALY BMS package, including the BMS module, NTC sensor, sampling cable, and instruction manual.

The package includes the following items:

- 3.2V LiFePO4 BMS (1 unit)

- NTC sensor (1 unit)

- Sampling cable (1 unit)

- Instruction Manual (1 unit)

4. Specifications

The DALY BMS 4S 200A LiFePO4 module is designed for 4-series LiFePO4 battery packs. Key specifications are detailed below:

- Product Dimensions: 4.72 x 9.25 x 2.05 inches

- Item Weight: 3.97 pounds (1800 Grams)

- Input Voltage: 3.75 Volts (per cell nominal)

- Brand: DALY

- Manufacturer: Dongguan Daly Electronics Co., Ltd

Figure 4: Detailed product specifications including discharge current, overcharge/overdischarge voltage, and physical dimensions.

Figure 5: Table showing detailed parameters for LiFePO4 4S BMS, including discharge current, inner resistance, charge voltage, and various protection thresholds.

Figure 6: Table showing detailed parameters for LiFePO4 4S Smart BMS. Note: This product is a Standard BMS, not a Smart BMS, and does not have communication functions.

5. Setup and Installation

Proper installation is crucial for the safe and optimal performance of your DALY BMS. Follow these steps carefully.

5.1. Prepare Materials

Video 2: This video demonstrates the necessary tools and materials for BMS wiring, including the BMS module, sampling cables, ceramic scissors, a multimeter, and a soldering iron. It also provides guidance on appropriate soldering temperatures for both novices and professionals.

5.2. Identifying Sampling Points

Before connecting the BMS, it is essential to correctly identify the sampling points on your battery pack. This ensures accurate voltage monitoring and balancing.

Video 3: This video demonstrates how to determine the sampling points on a battery pack using a multimeter. It explains how to identify the total negative electrode (B-), the connection points between cells (B1, B2, B3, etc.), and the total positive electrode (B+). The video emphasizes checking voltage increases sequentially to confirm correct sampling point identification.

- Total Negative Electrode (B-): The first sampling point is the total negative electrode of the battery pack. Mark this as B-.

- Cell Connection Points (B1, B2, etc.): Subsequent sampling points are the connection points between the negative electrode of one cell and the positive electrode of the next cell in series. For example, B1 is the connection between the negative of the second cell and the positive of the first cell. Continue this for all cells.

- Total Positive Electrode (B+): The last sampling point is the total positive electrode of the battery pack. Mark this as B+.

- Verification with Multimeter: Use a multimeter set to DC voltage to verify the sampling points. Place the black probe on B- and the red probe on each subsequent sampling point (B1, B2, ..., B+). The voltage reading should increase incrementally (approximately 3V-3.7V per cell for LiFePO4) as you move from B1 to B+. If the voltage does not increase sequentially, your sampling points are incorrect.

5.3. Wiring Connection

Once sampling points are identified and verified, proceed with wiring the BMS to the battery pack. The sampling cable has a black wire (B-) and several red wires (B1, B2, ..., B+).

Figure 7: A detailed wiring diagram illustrating the connection of the sampling cable and output wires to the battery pack and BMS. This diagram is crucial for correct installation.

- Solder Sampling Cables:

- Connect the black wire of the sampling cable to the total negative terminal (B-) of the battery pack.

- Connect the first red wire to the positive terminal of the first battery string (B1).

- Connect the second red wire to the positive terminal of the second battery string (B2), and so on, until all strings are connected.

- The last red wire connects to the total positive terminal (B+) of the battery pack.

- Check Cable Connections: After connecting the cables, measure the voltage between two adjacent cables starting from the header. Ensure there are no wrong connections or missing connections.

- Connect Output Wires: Connect the B- wire of the BMS to the total negative terminal of the battery pack. Then, plug the sampling cable to the BMS. After activating the BMS, make sure that the voltage (battery voltage) between B+ & B- and the voltage between P+ & P- are consistent.

5.4. Important Wiring Considerations

Video 4: This video highlights common errors during BMS wiring, including incorrect use of wiring harnesses, inserting the BMS before welding, virtual welding, and incorrect P-line/B-line connections. It provides visual examples of these mistakes and their potential consequences, such as component breakdown or short circuits.

- Use Correct Wiring: Ensure the wiring harness used is specifically designed for your DALY BMS model. Using incorrect wiring from different manufacturers can lead to poor contact or socket shedding.

- Connect BMS Last: Do not insert the BMS module until all battery wires are correctly welded and verified. Inserting the BMS prematurely, especially if wires are crossed, can lead to breakdown of internal components.

- Avoid Virtual Welding: Ensure all solder joints are strong and complete. Virtual welding (poor contact) can lead to voltage leakage and damage over time, potentially causing the electric car to stop functioning.

- Verify P-line and B-line: Incorrect connection of the P-line (output) and B-line (battery negative) can cause short circuits, burn out the sampling line, or even the entire protective plate. Always double-check these critical connections.

6. Operating the BMS

Once installed, the DALY BMS operates automatically to protect your battery pack. It continuously monitors cell voltages, currents, and temperatures.

- Overcharge Protection: Prevents cells from being charged beyond their safe voltage limit.

- Overdischarge Protection: Stops discharge when cells reach their minimum safe voltage, preventing damage.

- Overcurrent Protection: Limits current during discharge to prevent damage from excessive loads.

- Short Circuit Protection: Immediately cuts off current in case of a short circuit.

- Temperature Protection: Monitors battery temperature and intervenes if it exceeds safe operating limits.

- Balancing Function: Actively balances cell voltages to ensure all cells are charged and discharged uniformly, extending battery life.

Figure 8: Visual representation of the basic protection functions provided by the DALY BMS, including over-charge, over-discharge, over-current, short-circuit, waterproof, anti-vibration, temperature, and electrostatic protection.

The BMS is suitable for various Li-batteries in diverse scenarios, including home energy storage, inverters, aerial work vehicles, marine energy storage, ATVs, floor sweepers, RVs, tour cars, low-speed vehicles, golf carts, and forklifts.

Figure 9: Examples of various applications where the DALY BMS can be utilized, demonstrating its versatility across different battery types and usage environments.

7. Maintenance

- Regularly inspect all wiring and connections for signs of wear, corrosion, or damage.

- Keep the BMS module clean and free from dust and debris.

- Ensure adequate ventilation around the BMS, especially for models with cooling fans, to prevent overheating.

- Avoid exposing the BMS to extreme temperatures or humidity.

8. Troubleshooting

If you encounter issues with your DALY BMS, consider the following common problems and solutions:

- Battery Not Charging/Discharging:

- Check all wiring connections for correctness and secure contact. Refer to the wiring diagram.

- Verify that the sampling points are correctly identified and connected. Incorrect sampling can prevent proper operation.

- Ensure the BMS was inserted after all battery wiring was completed and verified.

- Inspect for any signs of internal component damage on the BMS, which might occur from incorrect initial wiring.

- BMS Overheating:

- Ensure proper ventilation around the BMS.

- Check if the load current exceeds the BMS's rated continuous discharge current.

- Inconsistent Cell Voltages (Balancing Issues):

- Confirm that the sampling wires are securely connected to each cell's positive terminal.

- Allow sufficient time for the balancing function to work, especially with new or heavily unbalanced packs.

For further assistance, please contact DALY customer service.

9. Warranty and Support

DALY provides a quality guarantee for its products. The package includes an instruction manual and the product is ISO/FCC/RoHS/PSE/CE APPROVED.

For any technical support or customer service inquiries, please contact DALY's online customer service. They offer 24-hour one-on-one customer service and lifetime technical support.

If you need smart BMS, active balancer, parallel module or other accessories, please contact online customer service.