1. Introduction

This manual provides instructions for the installation, operation, and maintenance of the Edwards EMF10 Oil Mist Filter. The EMF10 is designed to reduce oil mist emissions from rotary vane vacuum pumps, ensuring a cleaner working environment and compliance with health and safety regulations. It is compatible with various Edwards RV and E2M series vacuum pumps.

2. Safety Information

Always consult the primary instruction manual for your specific Edwards vacuum pump before installing or operating the EMF10 oil mist filter. Ensure the vacuum pump is switched off and isolated from power before performing any installation or maintenance procedures. Wear appropriate personal protective equipment (PPE) as required by your facility's safety guidelines. The filter body is semi-transparent, allowing for visual monitoring of the oil level; however, avoid direct contact with used oil.

3. Product Description and Components

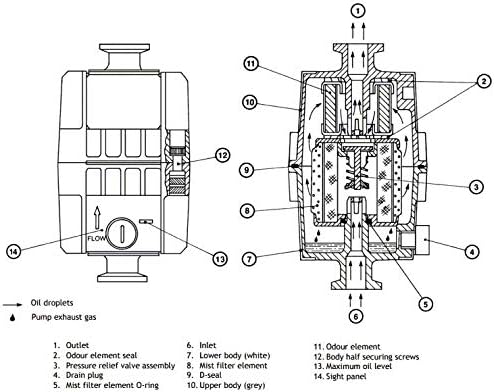

The Edwards EMF10 Oil Mist Filter is an exhaust filter assembly designed to capture oil mist from the exhaust of rotary vane vacuum pumps. It features a durable plastic body and an epoxy-impregnated glass fiber oil filter element. An integral pressure relief valve opens if the oil element becomes blocked, preventing overpressure.

Figure 1: Edwards EMF10 Oil Mist Filter with its mist and odor filter elements.

The EMF10 assembly includes:

- EMF10 Oil Mist Filter unit (Part Number: A462-26-000)

- NW25 clamp

- Centering ring and O-ring

- NW25 to 3/4 BSP adapter

- One oil filter element (Part Number: A223-04-198)

- One odor element (Part Number: A223-04-079)

Figure 2: Close-up view of the oil mist filter element (green) and odor element (black mesh).

Figure 3: Internal component diagram of the EMF10. Key components include the inlet, outlet, mist filter element, odor element, pressure relief valve, and drain plug.

4. Setup and Installation

The EMF10 filter is designed for easy connection to the exhaust port of compatible Edwards rotary vane vacuum pumps. Ensure all connections are secure to prevent leaks.

- Ensure the vacuum pump is turned off and disconnected from its power source.

- Locate the exhaust port on your vacuum pump.

- Attach the EMF10 filter to the pump's exhaust port using the provided NW25 clamp, centering ring, and O-ring. If necessary, use the NW25 to 3/4 BSP adapter. Ensure the filter is oriented correctly with the 'FLOW' arrow pointing away from the pump.

- Secure the clamp firmly to create a vacuum-tight seal.

- Verify that the filter is stable and properly supported.

Figure 4: Installation diagram illustrating the connection of the EMF10 filter to a vacuum pump exhaust port.

Figure 5: The EMF10 Oil Mist Filter shown installed on an Edwards RV8 vacuum pump.

5. Operating Instructions

Once installed, the EMF10 operates passively to filter oil mist from the pump exhaust. No specific operational controls are required for the filter itself.

- Start your vacuum pump according to its operating instructions.

- The EMF10 will begin filtering oil mist from the exhaust gas.

- Monitor the semi-transparent lower body of the filter to observe the collected oil level.

- If the oil element becomes blocked, an integral pressure relief valve will open to prevent excessive back pressure on the pump. This indicates that the filter element requires replacement.

6. Maintenance

Regular maintenance, primarily the replacement of filter elements, is crucial for optimal performance and to maintain a clean exhaust. The oil filter element is highly efficient at 99.999% DOP test and is azide proof.

6.1. Replacing Filter Elements

The oil mist filter element (A223-04-198) and odor element (A223-04-079) should be replaced periodically, or when the pressure relief valve activates, indicating a blocked element.

- Turn off the vacuum pump and disconnect it from the power supply.

- Allow the pump and filter to cool down if they have been operating.

- Carefully detach the EMF10 filter from the vacuum pump.

- Unscrew the lower body of the filter from the upper body.

- Remove the old oil mist and odor filter elements. Dispose of them according to local regulations for contaminated waste.

- Insert the new oil mist filter element (A223-04-198) and odor element (A223-04-079) into their respective positions.

- Reassemble the filter by screwing the lower body back onto the upper body, ensuring a tight seal.

- Reattach the EMF10 filter to the vacuum pump as described in the Setup and Installation section.

6.2. Draining Collected Oil

The EMF10 collects oil from the pump exhaust. This oil should be drained periodically to prevent overfilling and re-entrainment into the exhaust stream. Use the drain plug located at the bottom of the filter to drain the collected oil into a suitable waste container. Dispose of used oil responsibly according to environmental regulations.

7. Troubleshooting

If you encounter issues with your EMF10 oil mist filter, consider the following:

- Excessive Oil Mist Emission: Check if the filter elements are correctly installed. If the elements are old or saturated, replace them.

- High Back Pressure / Pressure Relief Valve Activation: This indicates a blocked oil filter element. Replace the oil filter element immediately.

- Leaks at Connections: Ensure all clamps and seals are properly tightened and that O-rings are in good condition and correctly seated.

For persistent issues, refer to your vacuum pump's manual or contact technical support.

8. Specifications

| Feature | Specification |

|---|---|

| Model | EMF10 |

| Part Number | A462-26-000 |

| Compatible Pump Models | RV3, RV5, RV8, RV12, E2M2, E2M5, E2M8, E2M12 |

| Inlet & Exhaust Flanges | ISO KF25 (NW25) |

| Dimensions (Height x Width) | 7.5 x 5 inches (approximately 190.5 x 127 mm) |

| Weight | 1.5 lb (approximately 0.68 kg) |

| Body Material | Durable Plastic |

| Oil Filter Element Material | Epoxy Impregnated Glass Fiber |

| Replacement Oil Filter Part Number | A223-04-198 |

| Replacement Odor Element Part Number | A223-04-079 |

| Filtration Efficiency | 99.999% DOP test |

9. Warranty and Support

For warranty information, technical support, or to purchase replacement parts, please contact the seller or the official Edwards distributor from whom the product was acquired. Ensure you have your product model number (EMF10) and part number (A462-26-000) available when seeking support.