1. Introduction

This instruction manual provides essential information for the safe and effective use of your Bessey GZ50-12KG All-Steel F-Type Screw Clamp. Please read this manual thoroughly before operating the clamp to ensure proper function, safety, and longevity of the tool. This clamp is designed for powerful and precise clamping applications in various workholding scenarios.

2. Safety Instructions

Always observe the following safety precautions when using the Bessey GZ50-12KG screw clamp:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, to protect against flying debris.

- Ensure the workpiece is stable and securely positioned before applying clamping force.

- Do not exceed the maximum clamping force of 5,000 N (approximately 1,124 lbs) to prevent damage to the clamp or workpiece.

- Inspect the clamp before each use for any signs of damage, wear, or deformation. Do not use a damaged clamp.

- Keep hands and fingers clear of the clamping area to avoid pinching injuries.

- Use the correct size clamp for the task. The GZ50-12KG has a 500mm rail length and 120mm throat depth.

- Store the clamp in a dry, clean place away from moisture and corrosive materials.

3. Product Overview

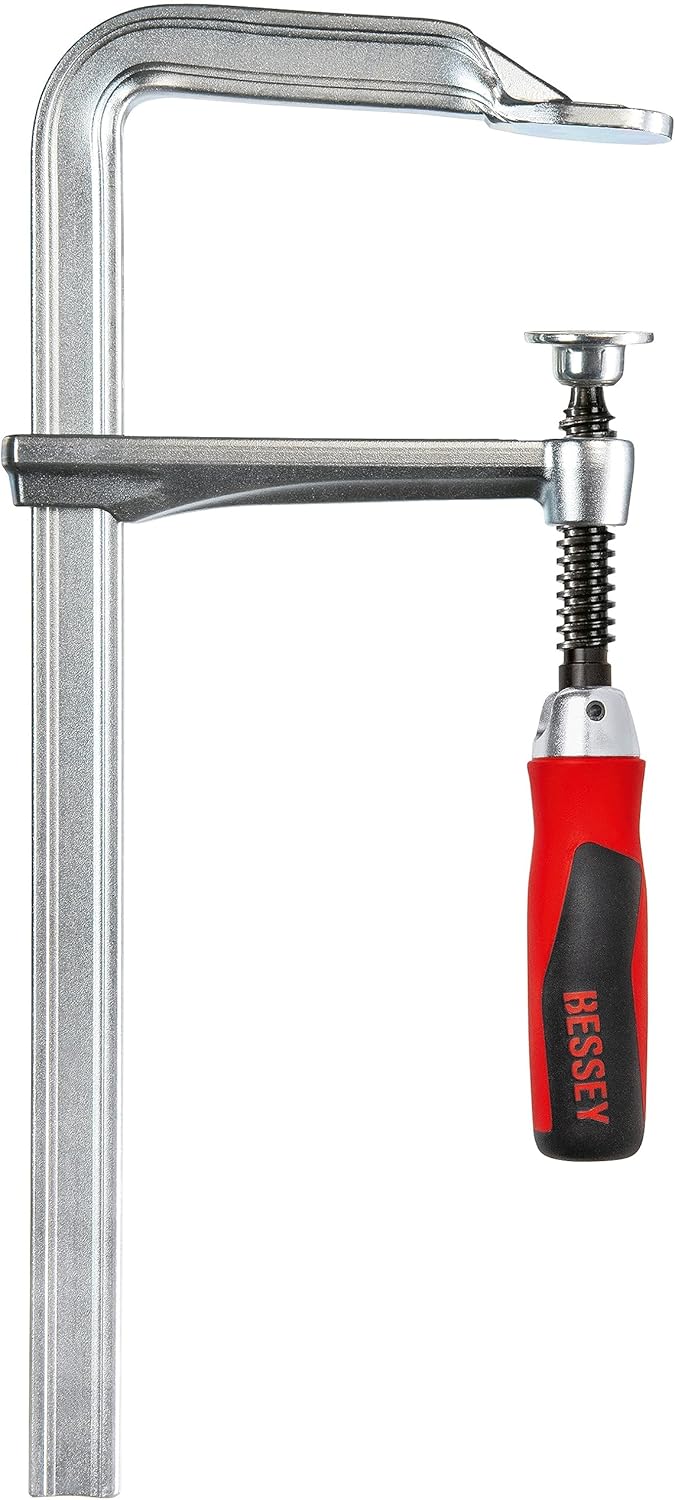

The Bessey GZ50-12KG is an all-steel F-type screw clamp designed for robust and ergonomic operation. Key components include the fixed jaw, sliding jaw, rail, spindle, and the unique 2-component plastic handle.

Figure 1: Front view of the Bessey GZ50-12KG All-Steel F-Type Screw Clamp. This image displays the full length of the clamp, highlighting the fixed jaw, sliding jaw, and the ergonomic handle with the Bessey logo.

Figure 2: Angled view of the Bessey GZ50-12KG Screw Clamp, showing the robust all-steel construction and the design of the fixed and sliding jaws. The handle is visible in its standard position.

Key Features:

- All-Steel Construction: Provides durability and resistance to vibrations, reducing the need for frequent retightening.

- Ergonomic 2-Component Handle: Designed for comfortable grip and efficient power transfer.

- 90° Swivel Handle: Allows for increased leverage during tightening, reducing user effort.

- 360° Rotating Handle: Prevents the handle from obstructing the rail during clamping, especially in tight spaces.

- High Clamping Force: Capable of achieving up to 5,000 N (approximately 1,124 lbs) of clamping pressure.

- Dimensions: 500mm rail length and 120mm throat depth.

4. Setup

The Bessey GZ50-12KG screw clamp requires minimal setup before use. Ensure the clamp is clean and free of debris.

- Unpack the clamp: Carefully remove the clamp from its packaging.

- Inspect for damage: Before first use, visually inspect the entire clamp for any manufacturing defects or shipping damage.

- Familiarize yourself with components: Identify the fixed jaw, sliding jaw, rail, spindle, and handle.

5. Operating Instructions

Follow these steps for effective and safe operation of your Bessey GZ50-12KG screw clamp:

- Position the Workpiece: Place the material to be clamped between the fixed and sliding jaws. Ensure the workpiece is stable and supported.

- Adjust the Sliding Jaw: Loosen the sliding jaw by rotating the handle counter-clockwise slightly, then slide it along the rail until it is close to the workpiece.

- Apply Clamping Force: Rotate the handle clockwise to tighten the spindle and apply clamping force. The ergonomic 2-component handle provides a comfortable grip.

- Utilize Swivel Handle for Leverage: For increased leverage and easier tightening, especially when high clamping force is required, the handle can be swiveled 90 degrees.

Figure 3: The Bessey GZ50-12KG clamp demonstrating the handle swiveled 90 degrees for enhanced leverage during tightening. This feature reduces user effort.

- Adjust Handle Position in Tight Spaces: If the handle interferes with the rail or surrounding objects during tightening, it can be rotated 360 degrees while swiveled. This allows for continuous tightening without obstruction.

- Release Clamping Force: To release the clamp, rotate the handle counter-clockwise until the pressure is relieved and the sliding jaw can be moved freely.

Application Examples:

Figure 4: A craftsman utilizing the Bessey GZ50-12KG clamp to secure components during cabinet assembly. The clamp's design allows for effective use even in confined spaces.

Figure 5: An individual applying the Bessey GZ50-12KG clamp to a vertical beam, demonstrating its versatility for securing materials in various orientations.

Figure 6: Multiple Bessey GZ50-12KG clamps in use to secure a larger workpiece, illustrating their capability for heavy-duty applications and stable workholding.

6. Maintenance

Regular maintenance ensures the optimal performance and extends the lifespan of your Bessey GZ50-12KG screw clamp:

- Cleaning: After each use, wipe down the clamp with a clean, dry cloth to remove dust, debris, and any residues.

- Lubrication: Periodically apply a light machine oil to the spindle threads and the sliding mechanism of the jaw to ensure smooth operation. Avoid over-lubrication.

- Storage: Store the clamp in a dry environment to prevent rust. Keep it away from direct sunlight and extreme temperatures.

- Inspection: Regularly check for any loose parts, bent components, or signs of excessive wear. Address any issues promptly.

7. Troubleshooting

If you encounter issues with your Bessey GZ50-12KG screw clamp, refer to the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Clamp is difficult to tighten or loosen. | Lack of lubrication on spindle threads; debris in mechanism. | Clean the spindle and apply a light lubricant. Check for and remove any obstructions. |

| Sliding jaw sticks. | Dirt or rust on the rail; insufficient lubrication. | Clean the rail thoroughly and apply a thin layer of lubricant. |

| Clamp does not hold workpiece securely. | Insufficient clamping force applied; worn jaws; incorrect clamp size for workpiece. | Ensure adequate force is applied. Inspect jaws for wear. Verify clamp capacity matches workpiece. |

If problems persist, contact Bessey customer support for further assistance.

8. Specifications

| Feature | Detail |

|---|---|

| Model Number | GZ50-12KG |

| Material | Alloy Steel |

| Rail Length | 500 mm |

| Throat Depth | 120 mm |

| Maximum Clamping Force | 5,000 N (approx. 1,124 lbs) |

| Item Weight | 1.82 Kilograms (approx. 4 pounds) |

| Product Dimensions (L x W x H) | 23.62 x 6.89 x 1.38 inches |

| Handle Style | Ergonomic 2-Component, Swivel (90°), Rotate (360°) |

9. Warranty and Support

For information regarding warranty coverage, product support, or spare parts for your Bessey GZ50-12KG All-Steel F-Type Screw Clamp, please refer to the official Bessey website or contact their customer service department directly. Keep your purchase receipt as proof of purchase.

Manufacturer: BESSEY

Website: www.bessey.de/en/ (Example link, actual link may vary)

Contact: Refer to the manufacturer's website for regional contact information.