1. Introduction and Overview

This manual provides essential information for the safe and effective operation, maintenance, and troubleshooting of your Strongway 20-Ton Air/Hybrid Short Bottle Jack. This robust jack features a completely welded design with a drop-forged base, ensuring durability for demanding commercial applications. It offers a versatile lifting range from 8 1/4 inches to 15 1/2 inches, making it suitable for a variety of heavy-duty tasks.

Typical applications include roadside truck emergency rescue, agriculture equipment repair, industrial equipment repair, and lifting mobile homes or other heavy machinery. The chrome-plated ram is designed to resist rust and wear, enhancing the jack's longevity in outdoor environments.

Image 1.1: The Strongway 20-Ton Air/Hybrid Short Bottle Jack, showcasing its compact design and air hose connection.

2. Safety Information

WARNING: Read and understand all instructions and warnings in this manual before operating this product. Failure to follow these instructions may result in serious injury or property damage.

- Always wear ANSI-approved safety goggles and heavy-duty work gloves during setup and use.

- Do not exceed the rated load capacity of 20 tons.

- Use this jack only on a hard, level surface capable of supporting the load.

- Ensure the load is centered on the saddle. Off-center loads can cause the jack to tip.

- Never work under a lifted load without supporting it with appropriate jack stands.

- Do not use the jack for purposes other than lifting. It is not designed for supporting a load for extended periods.

- Keep hands and feet clear of the jack's moving parts and the load during lifting and lowering.

- Inspect the jack before each use for any signs of damage, leaks, or wear. Do not use if damaged.

- Keep children and bystanders away from the work area.

- Release pressure slowly when lowering the load.

- Ensure the air supply pressure is within the specified range (100-120 PSI) when using the air-assist feature.

3. Product Features

The Strongway 20-Ton Air/Hybrid Short Bottle Jack incorporates several design elements for enhanced performance and durability:

- High-Grade Steel Construction: Built with robust steel and a lead-free paint finish, providing excellent resistance against rust and corrosion.

- Easy Cleanup Paint: The paint finish is also resistant to oil, grease, and dirt, simplifying maintenance and cleaning.

- Completely Welded Design with Drop-Forged Base: Ensures structural integrity and stability, contributing to the jack's longevity and safe operation.

- Treated, Polished Piston Ram: Designed to resist skiving, ensuring smooth operation and extended service life.

- Screw-Top Adjustment: Provides up to 3 1/4 inches of additional height adjustment, offering greater versatility for various lifting tasks.

- Quick-Connect Feature: Enhances portability and ease of setup by allowing quick attachment and detachment of the air hose.

Image 3.1: The jack's robust welded steel construction, highlighting its durability.

Image 3.2: Demonstrating the jack's adjustable lifting range from 8-1/4 inches to 15-1/2 inches.

Image 3.3: The quick-connect feature for easy air hose attachment, enhancing portability.

Image 3.4: The jack's 20-ton capacity, illustrating its industrial lifting power.

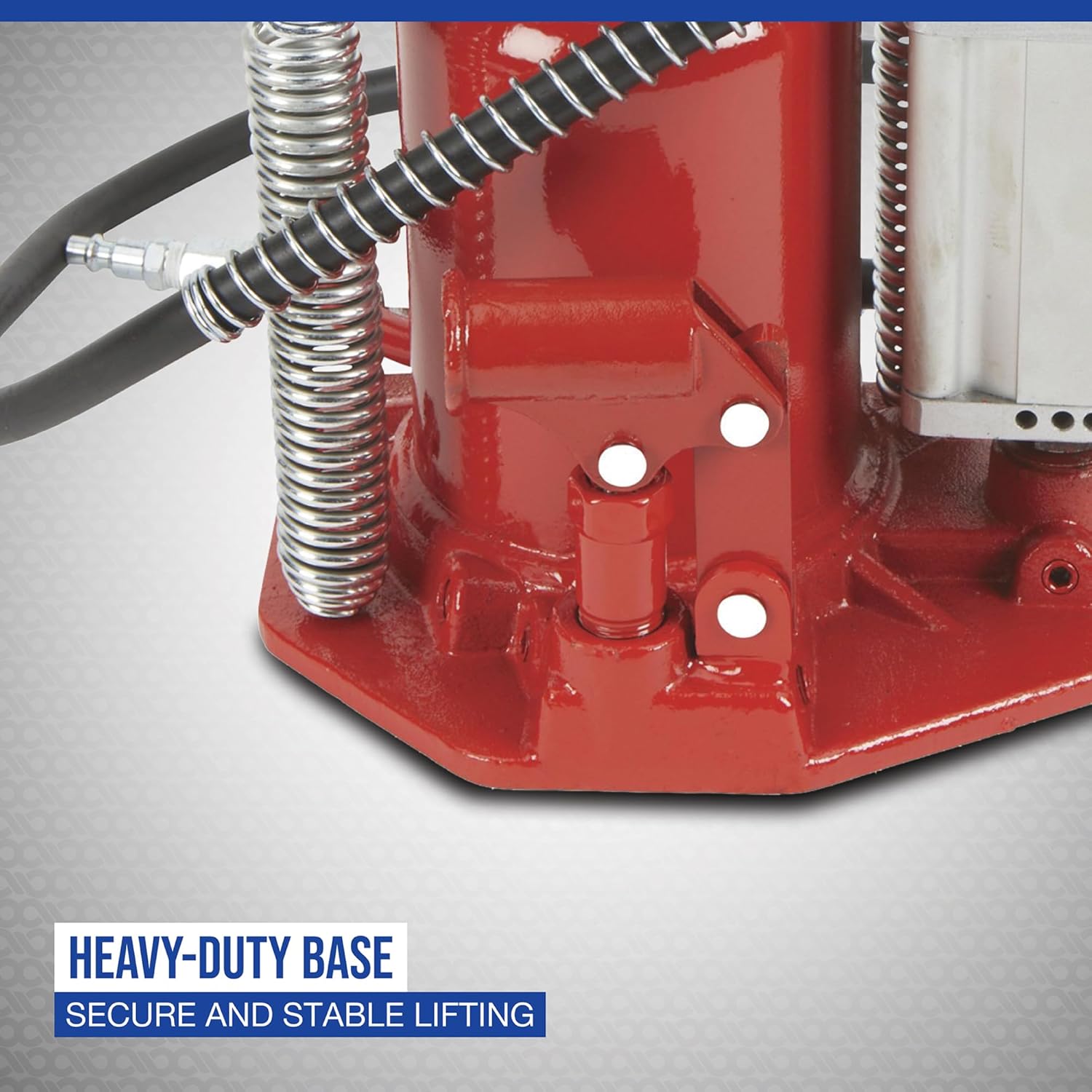

Image 3.5: A close-up view of the jack's heavy-duty base, designed for secure and stable lifting.

4. Setup

4.1 Initial Inspection

Before first use, carefully inspect the jack for any shipping damage, loose parts, or missing components. Ensure all connections are secure. If any damage is found, do not use the jack and contact customer support.

4.2 Bleeding the Air System (If Applicable)

Air pockets can form in the hydraulic system during shipping or storage, affecting performance. To bleed the system:

- Open the release valve by turning it counter-clockwise.

- Remove the oil filler plug.

- Pump the handle 5-10 full strokes to force air out.

- Close the release valve.

- Replace the oil filler plug.

- Test the jack for proper operation. Repeat if necessary.

4.3 Preparing the Work Area

Ensure your work area is clean, well-lit, and free of obstructions. The surface must be hard, level, and capable of supporting the weight of the jack and the load. Chock any wheels on the vehicle or equipment not being lifted to prevent accidental movement.

5. Operating Instructions

5.1 Lifting the Load (Manual Operation)

- Position the jack on a hard, level surface directly under the lifting point of the load. Ensure the saddle is centered.

- Close the release valve firmly by turning it clockwise.

- Insert the handle into the handle socket.

- Pump the handle up and down to raise the saddle. Continue pumping until the load reaches the desired height.

- Immediately place appropriately rated jack stands under the load at designated support points.

- Slowly open the release valve to lower the load onto the jack stands. The jack is for lifting only, not for sustained support.

5.2 Lifting the Load (Air-Assist Operation)

- Position the jack as described in step 1 of manual operation.

- Close the release valve firmly by turning it clockwise.

- Connect an air hose (not included) to the quick-connect fitting on the jack. Ensure the air supply provides 100-120 PSI.

- Open the air valve on the jack to begin lifting. The jack will raise automatically using air pressure.

- Once the desired height is reached, close the air valve.

- Immediately place appropriately rated jack stands under the load at designated support points.

- Slowly open the release valve to lower the load onto the jack stands.

Image 5.1: A user positioning the jack under heavy equipment for lifting.

Image 5.2: The jack in action, demonstrating its lifting capability and stable placement.

Image 5.3: A user operating the jack handle to raise the load.

5.3 Lowering the Load

- Ensure the area around the load is clear of personnel and obstructions.

- If jack stands were used, lift the load slightly off the jack stands using the jack.

- Remove the jack stands.

- Slowly turn the release valve counter-clockwise to lower the load. Control the descent rate by adjusting the valve opening.

- Once the load is fully lowered, remove the jack.

6. Maintenance

Regular maintenance is crucial for the safe and efficient operation of your Strongway bottle jack.

6.1 Hydraulic Oil Level

Check the hydraulic oil level every three months or after extensive use. Use only high-quality hydraulic jack oil. Do not use brake fluid or motor oil.

- With the jack fully lowered, remove the oil filler plug.

- The oil level should be just below the filler hole.

- Add oil if necessary, ensuring no air enters the system.

- Replace the oil filler plug.

6.2 Lubrication

Lubricate all moving parts, including the ram and pump mechanism, with light machine oil periodically to ensure smooth operation and prevent rust.

6.3 Cleaning and Storage

Keep the jack clean and free of dirt, grease, and moisture. Store the jack in a dry, protected area with the ram fully retracted to prevent corrosion and extend seal life.

7. Troubleshooting

If you encounter issues with your jack, refer to the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Jack will not lift load. | Release valve open; Low hydraulic oil; Air in system; Overload. | Close release valve; Check/add oil; Bleed system; Reduce load. |

| Jack lifts slowly or erratically. | Low hydraulic oil; Air in system; Worn seals. | Check/add oil; Bleed system; Contact service for seal replacement. |

| Jack will not hold load. | Release valve not fully closed; Internal leak; Worn seals. | Ensure valve is fully closed; Contact service for internal leak or seal repair. |

| Ram does not retract fully. | Air in system; Obstruction; Low oil. | Bleed system; Check for obstructions; Check/add oil. |

| Air-assist not working. | Insufficient air pressure; Air valve closed; Air hose disconnected. | Ensure 100-120 PSI supply; Open air valve; Check hose connection. |

8. Specifications

| Specification | Value |

|---|---|

| Load Capacity | 20 tons |

| Minimum Lift Height | 8 1/4 inches |

| Maximum Lift Height | 15 1/2 inches |

| Screw-Top Adjustment | Up to 3 1/4 inches |

| Item Weight | 33 pounds |

| Package Dimensions | 11.5 x 10 x 7.5 inches |

| Construction Material | High-grade steel, chrome-plated ram |

| Air Pressure Requirement | 100-120 PSI (for air-assist) |

9. Warranty and Support

For specific warranty information regarding your Strongway 20-Ton Air/Hybrid Short Bottle Jack, please refer to the documentation provided at the time of purchase or contact the retailer/manufacturer directly. Strongway products are designed for durability and performance.

If you require technical assistance, replacement parts, or have questions not covered in this manual, please contact Strongway customer support or the authorized service center where you purchased the product. Always provide the model number and purchase date when seeking support.