1. Introduction

This manual provides detailed instructions for the safe and efficient operation of the Hanchen SP301 Manual Strapping Tool. This versatile tool is designed for tensioning, cutting, and sealing 13mm PP (Polypropylene) bands, making it suitable for various packaging tasks in warehouses, garages, and for securing goods on pallets or in wooden crates.

The Hanchen SP301 is engineered for ease of use, featuring a simple, labor-saving design that allows for high-efficiency packaging. Its integrated cutter eliminates the need for additional tools like scissors, streamlining the strapping process.

2. Product Overview

The Hanchen SP301 is a 3-in-1 manual strapping tool that combines the functions of tensioning, cutting, and sealing PP bands. It features an ergonomic handle design for comfortable use during extended operations.

Figure 2.1: Overall view of the Hanchen SP301 Manual Strapping Tool. This image displays the complete tool with its tensioning, cutting, and sealing components, along with the blue-handled levers.

Key Features:

- 3-in-1 Functionality: Performs tensioning, cutting, and sealing with a single tool.

- Integrated Cutter: Eliminates the need for separate cutting tools, improving efficiency.

- Ergonomic Design: Handles are shaped for a comfortable grip, reducing fatigue during prolonged use.

- Durable Construction: Made from alloy steel and iron for robust performance.

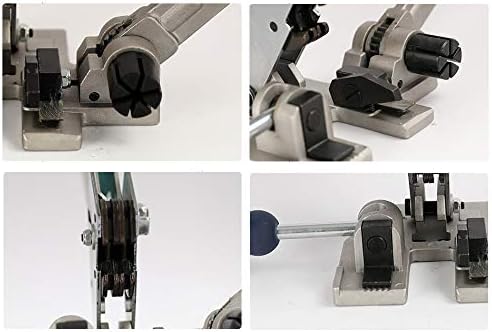

Figure 2.2: Close-up views of the tool's components. This collage shows the tensioning teeth, the strap cutting mechanism, and the sealing crimper, highlighting the functional parts of the SP301.

3. Specifications

| Specification | Detail |

|---|---|

| Model Number | SP301 |

| Dimensions (L x W x H) | 360mm x 130mm x 150mm |

| Compatible Band Type | PP (Polypropylene) Band |

| Compatible Band Width | 13mm |

| Weight | 2.5 kg |

| Materials | Polypropylene, Alloy Steel, Iron |

4. Setup

- Unpacking: Carefully remove the strapping tool from its packaging. Inspect the tool for any signs of damage during transit.

- Familiarization: Identify the main components: the tensioning lever, the cutting lever, the sealing mechanism, and the strap guides.

- Strap Preparation: Ensure you have a roll of 13mm PP strapping band and appropriate metal seals (buckles) if required for your application.

5. Operating Instructions

Follow these steps to effectively use the Hanchen SP301 strapping tool:

- Position the Strap: Wrap the PP band around the item to be strapped, ensuring it is snug and correctly positioned. Overlap the two ends of the strap.

- Insert Strap into Tensioner: Open the tensioning lever on the tool. Insert the bottom strap end through the tool's base and under the tensioning wheel. Insert the top strap end through the cutting mechanism and over the tensioning wheel.

- Tension the Strap: Operate the tensioning lever repeatedly to pull the strap tight around the package. Continue until the desired tension is achieved. Ensure the package is securely bound without causing damage.

- Apply the Seal: Once the strap is tensioned, place a metal seal (buckle) over the overlapping straps, positioning it within the tool's sealing mechanism.

- Seal the Strap: Press the sealing lever down firmly to crimp the metal seal, securing the two ends of the PP band together.

- Cut the Strap: After sealing, use the integrated cutting lever to cleanly cut the excess strap.

- Remove the Tool: Release all levers and carefully remove the strapping tool from the newly secured package.

Figure 5.1: The tool in operation, showing a close-up of the sealing mechanism. This image illustrates how the tool crimps the seal onto the PP band.

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your Hanchen SP301 strapping tool.

- Cleaning: After each use, wipe down the tool with a clean, dry cloth to remove any dust or strap residue. Pay attention to the tensioning wheel and cutting blade areas.

- Lubrication: Periodically apply a small amount of light machine oil to moving parts, such as pivots and the tensioning wheel mechanism, to ensure smooth operation. Avoid over-lubrication.

- Inspection: Regularly inspect the cutting blade and sealing jaws for wear or damage. Replace components if they show significant wear to maintain effective operation.

- Storage: Store the tool in a dry, clean environment, away from direct sunlight and extreme temperatures, to prevent corrosion and material degradation.

7. Troubleshooting

If you encounter issues while using the Hanchen SP301, refer to the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Strap not tensioning properly | Tensioning wheel clogged or worn; strap incorrectly inserted. | Clean the tensioning wheel. Ensure the strap is correctly threaded. Replace worn tensioning wheel if necessary. |

| Strap breaks during tensioning | Excessive tension applied; strap quality is poor; strap width/thickness incompatible. | Reduce tension. Use high-quality 13mm PP strap. |

| Poor or incomplete seal | Sealing jaws are dirty or worn; insufficient pressure applied to sealing lever; incorrect seal size. | Clean sealing jaws. Apply firm, consistent pressure. Use correct metal seals for 13mm PP band. Replace worn jaws if needed. |

| Strap cutter not working | Cutter blade is dull or damaged. | Inspect and replace the cutter blade if it is dull or damaged. |

8. Warranty and Support

For any questions, technical assistance, or warranty claims regarding your Hanchen SP301 Manual Strapping Tool, please contact your retailer or the manufacturer directly. Keep your purchase receipt as proof of purchase for warranty purposes.

Manufacturer: Hanchen