1. Introduction and Overview

This manual provides detailed instructions for the safe and efficient operation, setup, and maintenance of your Happybuy FR-770 Continuous Band Sealing Machine. This machine is designed for continuous sealing of various plastic film bags, offering a reliable solution for packaging needs.

The FR-770 features an electronic constant temperature mechanism and a stepless speed-adjusting transmission system, making it suitable for assembly line integration. Its robust construction and versatile sealing capabilities ensure consistent performance.

Figure 1: Happybuy FR-770 Continuous Band Sealing Machine, showing its main components including the conveyor belt and sealing mechanism.

2. Safety Instructions

Please read and understand all safety instructions before operating the machine. Failure to follow these instructions may result in injury or damage to the equipment.

- Ensure the machine is placed on a stable, level surface.

- Connect the machine to a grounded power outlet with the correct voltage (110V/60Hz).

- Keep hands and loose clothing away from moving parts, especially the conveyor belt and sealing area, during operation.

- Do not touch the heating elements directly as they can reach high temperatures. Allow sufficient time for cooling before maintenance.

- Never operate the machine with damaged power cords or plugs.

- Turn off and unplug the machine before performing any cleaning, maintenance, or adjustments.

- Keep children and unauthorized personnel away from the operating area.

- Use appropriate personal protective equipment (PPE) if necessary.

3. Product Components and Features

The Happybuy FR-770 is constructed with durable carbon steel and features pure copper heating and cooling blocks for efficient operation.

3.1 Key Components

- Control Panel: Includes Power, Heater, and Fan switches, a Speed knob, and a digital Temperature Controller.

- Conveyor Belt: Thickened for durability, allowing for continuous feeding of bags.

- Sealing Mechanism: Features heating and cooling blocks for precise and secure seals.

- Fixed Working Table: Provides a stable platform for bags during sealing.

- Embossing Wheel: Allows for printing production dates, times, or logos on the seal.

Figure 2: Detailed view of the control panel, showing the Power, Heater, and Fan switches, Speed knob, and digital Temperature Controller.

3.2 Enhanced Functionality

- Versatile Bag Compatibility: Suitable for various film materials including PP, PE, PV, OPP, PS, Kraft Paper, PE Bag, Aluminum Foil Bag, and Plastic Bag Film.

- Adjustable Sealing Width: The sealing width can be adjusted from 6-15 mm (0.24-0.59 inches) to accommodate different bag types.

- Adjustable Sealing Speed: The conveyor speed is adjustable from 0-16 m/min (0-52.49 ft/min) to match production demands.

- Embossing and Printing: The machine can be equipped with an embossing wheel and type wheel for printing dates, times, or other alphanumeric characters on the seal.

- Dual-Position Sealing: The machine can be configured for both horizontal and vertical sealing, adapting to different product types and packaging requirements.

Figure 3: The machine is compatible with various bag materials such as Kraft Paper, PE Bag, Aluminum Foil Bag, and Plastic Bag.

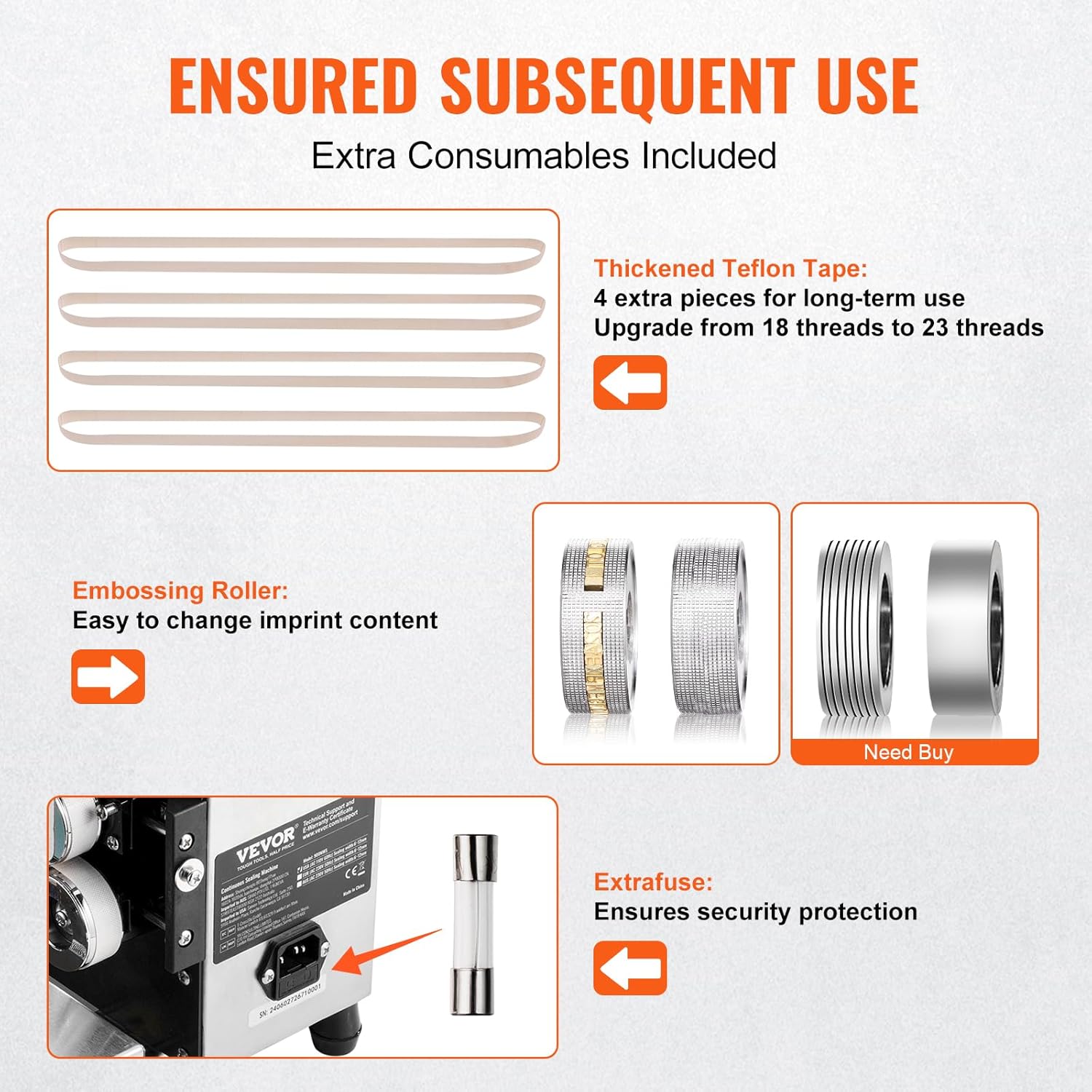

Figure 4: Included accessories such as thickened Teflon tape, an embossing roller for custom imprints, and an extra fuse for security protection.

4. Setup

- Unpacking: Carefully remove the machine and all accessories from the packaging. Inspect for any shipping damage.

- Placement: Position the machine on a sturdy, flat, and dry surface. Ensure adequate ventilation around the machine.

- Power Connection: Connect the power supply wire to the machine and then to a suitable 110V/60Hz grounded electrical outlet.

- Conveyor Table Adjustment: The conveying table's height and position can be adjusted to align with your specific bag dimensions and operational needs. Use the adjustment knobs to set the desired height and front/back position.

- Embossing Wheel Installation (Optional): If printing is required, install the embossing wheel and arrange the desired characters (numbers, letters) into the type wheel.

5. Operating Instructions

- Power On: Flip the POWER switch to the ON position.

- Activate Fan and Heater: Turn on the HEATER switch and the FAN switch. The fan helps cool the sealing area after heating.

- Set Temperature: Use the digital Temperature Controller to set the desired sealing temperature. The optimal temperature depends on the bag material and thickness. Start with a lower temperature and gradually increase if the seal is not strong enough. The range is 0 - 400 °C (32 °F - 752 °F).

- Set Sealing Speed: Adjust the SPEED knob to control the conveyor belt's speed. A slower speed generally allows for a stronger seal, while a faster speed increases throughput.

- Test Sealing: Before mass production, perform a test seal on a sample bag to ensure the temperature and speed settings are appropriate for your material.

- Begin Sealing: Place the open end of the bag onto the conveyor belt, guiding it into the sealing mechanism. The machine will automatically feed and seal the bag.

- Adjust Sealing Pressure: The pressure control button can be adjusted to accommodate different bag thicknesses, ensuring a consistent seal.

Video 1: Demonstration of the VEVOR Continuous Band Sealer in operation, showcasing its features and ease of use for various bag types and sealing adjustments.

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your sealing machine.

- Cleaning: Regularly clean the conveyor belt and sealing area to prevent residue buildup. Use a soft, dry cloth. Ensure the machine is unplugged before cleaning.

- Teflon Belt Inspection: Inspect the Teflon belts for wear and tear. Replace them if they show signs of damage or excessive wear. The machine includes extra Teflon belts for replacement.

- Component Check: Periodically check all screws and connections to ensure they are tight.

- Fuse Replacement: If the machine loses power, check the fuse. Replace it with the provided extra fuse if necessary.

7. Troubleshooting

Refer to this section for common issues and their solutions.

| Problem | Possible Cause | Solution |

|---|---|---|

| Machine does not power on. | No power supply; Blown fuse. | Check power connection and outlet; Replace fuse. |

| Poor seal quality (weak or incomplete). | Incorrect temperature setting; Too fast sealing speed; Worn Teflon belts; Insufficient pressure. | Increase temperature; Decrease speed; Replace Teflon belts; Adjust pressure control. |

| Bags not feeding smoothly. | Conveyor belt misalignment; Obstruction on conveyor. | Adjust conveyor table position; Clean conveyor belt. |

| Overheating or smoke. | Fan not operating; Blocked ventilation. | Ensure FAN switch is ON; Clear any obstructions from vents. |

8. Specifications

| Specification | Value |

|---|---|

| Model | FR-770 |

| Power | 500W (Heating power: 700W) |

| Pattern | Horizontal |

| Voltage | 110V/60 Hz |

| Seal Width | 6-15 mm (0.24-0.59 inch) |

| Sealing Speed | 0-16 m/min |

| Sealing Thickness | 0.02-0.08 mm (0.0008-0.03 inch) |

| Temperature Control Range | 0 - 400 °C (32 °F - 752 °F) |

| Conveyor Load (Max.) | 5.0 kg |

| Motor Power | 80W |

| Product Dimensions | 36 x 16 x 13 inches (91.4 x 40.6 x 33 cm) |

| Item Weight | 11 pounds (5 kg) |

| Material | Metal (Carbon Steel) |

Figure 5: Visual representation of the machine's dimensions and a summary of key technical specifications.

9. Warranty and Support

For warranty information, technical support, or to purchase replacement parts, please refer to the official Happybuy website or contact their customer service. The product includes a kit of necessary accessories and spare parts such as toothed belts, Teflon belts, and a fuse to support maintenance.

Visit the Happybuy Store for more information.