1. Introduction

This manual provides comprehensive instructions for the VDO Temperature Sender, Model 323064. This sender is engineered for accurate temperature measurement up to 300°F (150°C) and is widely utilized in various automotive applications, including Air-Cooled VW and Volkswagen engines. Proper installation and understanding of its operation are crucial for optimal performance and longevity.

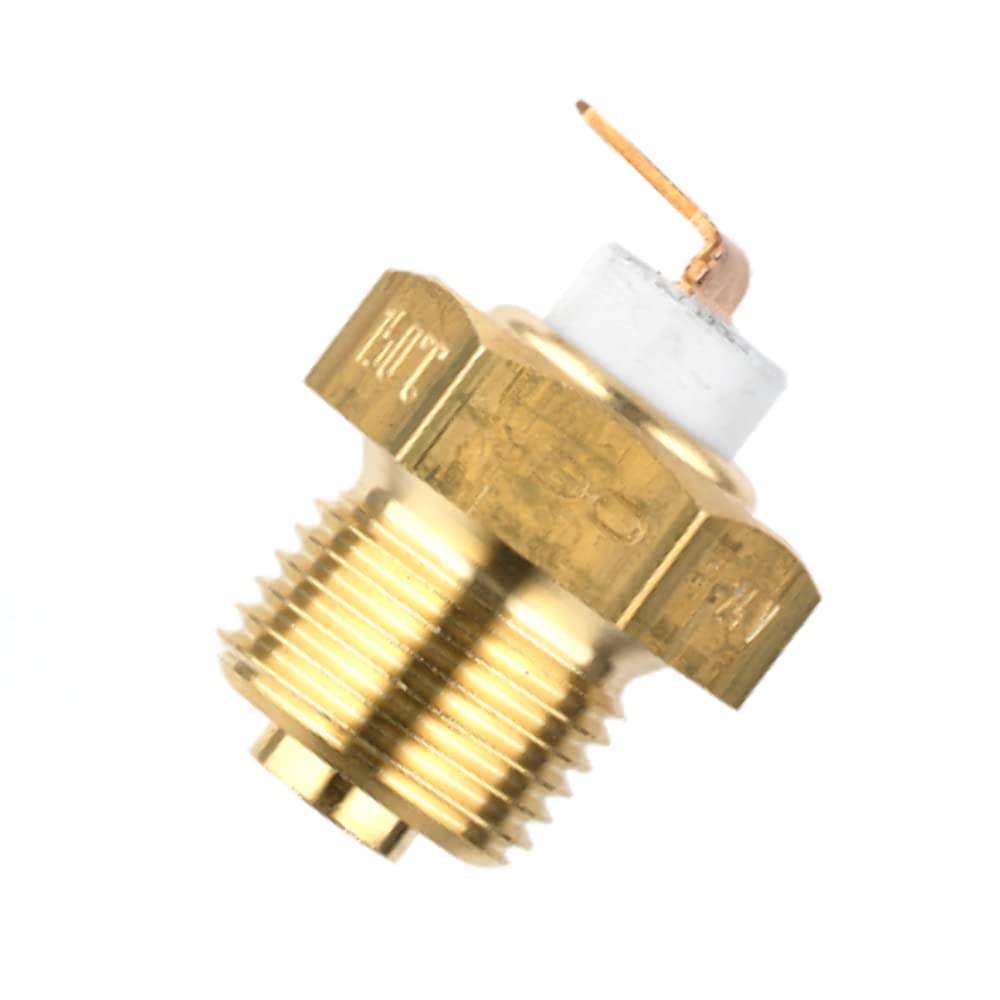

2. Product Overview

The VDO Temperature Sender 323064 is a robust and reliable component designed for monitoring engine or oil temperatures. Its construction ensures consistent performance in challenging automotive environments. Key features include:

- Temperature Range: 300°F (150°C)

- Thread Size: M18x1.5

- Ground Type: Standard

- Connection: .250" Spade at 90°

- Operating Voltage: 6-24V

3. Setup and Installation

3.1. Safety Precautions

- Ensure the engine is cool and the vehicle's electrical system is disconnected before installation.

- Wear appropriate personal protective equipment (PPE), such as gloves and eye protection.

- Refer to your vehicle's service manual for specific instructions regarding sensor replacement.

3.2. Mounting the Sender

- Locate the appropriate mounting port for the temperature sender. This is typically an M18x1.5 threaded port in the engine block, oil pan, or a dedicated adapter.

- Apply a suitable thread sealant to the sender's threads to prevent leaks.

- Carefully thread the sender into the port by hand to avoid cross-threading.

- Tighten the sender using an appropriate wrench. Do not overtighten, as this can damage the sender or the mounting port. Refer to vehicle specifications for torque values if available.

3.3. Electrical Connection

- Identify the electrical wire intended for the temperature gauge.

- Connect the wire to the .250" spade terminal on the sender. Ensure a secure connection.

- The sender utilizes a standard ground, meaning the sender body grounds through the engine block. Ensure good metal-to-metal contact between the sender and the engine for proper grounding.

- Reconnect the vehicle's electrical system and test the gauge functionality.

4. Operation

The VDO Temperature Sender operates by converting thermal energy into an electrical resistance signal. As the temperature of the medium (e.g., engine oil or coolant) increases, the internal resistance of the sender changes. This change in resistance is then detected by a compatible temperature gauge, which translates it into a visual temperature reading on the dashboard or instrument panel. The sender is designed to provide a linear and accurate response across its specified temperature range (up to 300°F / 150°C).

5. Maintenance

The VDO Temperature Sender is designed for long-term reliability and typically requires minimal maintenance. To ensure continued accurate operation:

- Periodic Inspection: Annually inspect the electrical connection for any signs of corrosion, looseness, or damage. Clean any corrosion with a suitable electrical contact cleaner.

- Wiring Integrity: Ensure the wiring leading to the sender is free from cuts, abrasions, or excessive tension.

- Leak Check: Periodically check the sender's mounting point for any signs of fluid leaks.

No internal user-serviceable parts are present. Do not attempt to disassemble the sender.

6. Troubleshooting

If you experience issues with your temperature sender or gauge, consider the following:

6.1. Incorrect Readings

- Gauge Compatibility: Ensure your temperature gauge is compatible with VDO senders. Different manufacturers may use different resistance curves.

- Ground Connection: Verify that the sender has a good ground connection through the engine block. A poor ground can lead to inaccurate readings.

- Wiring Issues: Check for damaged or corroded wiring between the sender and the gauge.

- Sender Calibration: While rare, a faulty sender can provide incorrect readings. If all other checks pass, consider testing the sender's resistance at known temperatures or replacing it.

6.2. No Reading

- Power to Gauge: Confirm the temperature gauge is receiving power.

- Open Circuit: Check for a broken wire or a disconnected terminal between the sender and the gauge.

- Faulty Sender: An internal failure in the sender can result in no signal.

6.3. Intermittent Readings

- Loose Connections: Inspect all electrical connections for looseness or intermittent contact.

- Vibration Damage: Check for any wiring damage caused by vibration.

7. Specifications

| Feature | Specification |

|---|---|

| Model Number | 323064 |

| Temperature Range | 300°F (150°C) |

| Thread Size | M18x1.5 |

| Ground Type | Standard |

| Electrical Connection | .250" Spade at 90° |

| Operating Voltage | 6-24V |

| Material | Brass |

| Manufacturer | VDO |

| Package Dimensions | 6.06 x 5.39 x 0.79 inches |

| Weight | 1.76 ounces |

8. Warranty and Support

For detailed warranty information, technical assistance, or to inquire about replacement parts, please contact VDO customer service directly. You can typically find contact information and support resources on the official VDO website. Please have your product model number (323064) and purchase details available when contacting support.

VDO Official Website: www.vdo-gauges.com