1. Introduction

This manual provides essential information for the proper use, installation, and maintenance of your Tormek DWC-200 Coarse Grit Diamond Wheel. Please read this manual thoroughly before using the product to ensure safe and efficient operation.

The Tormek DWC-200 is a high-quality diamond wheel designed for use with the Tormek T-2 sharpening machine. It is optimized for quickly sharpening dull or damaged kitchen knives and is suitable for various materials including steel, ceramic, and carbide.

2. Safety Information

Always observe the following safety precautions when handling and operating the diamond wheel and the sharpening machine:

- Always wear appropriate personal protective equipment, including eye protection, when operating the sharpening machine.

- Ensure the Tormek T-2 machine is unplugged before installing or removing the diamond wheel.

- Keep hands and fingers clear of the rotating wheel during operation.

- Do not use the wheel if it appears damaged or cracked.

- Store the diamond wheel in a dry, safe place away from children and unauthorized users.

- Refer to the Tormek T-2 sharpening machine's manual for additional safety guidelines.

3. Product Overview

The Tormek DWC-200 is a 200 mm (8-inch) diameter diamond wheel with a 360 grit coarse surface. It is specifically designed for efficient material removal to quickly restore a sharp edge to dull or damaged blades.

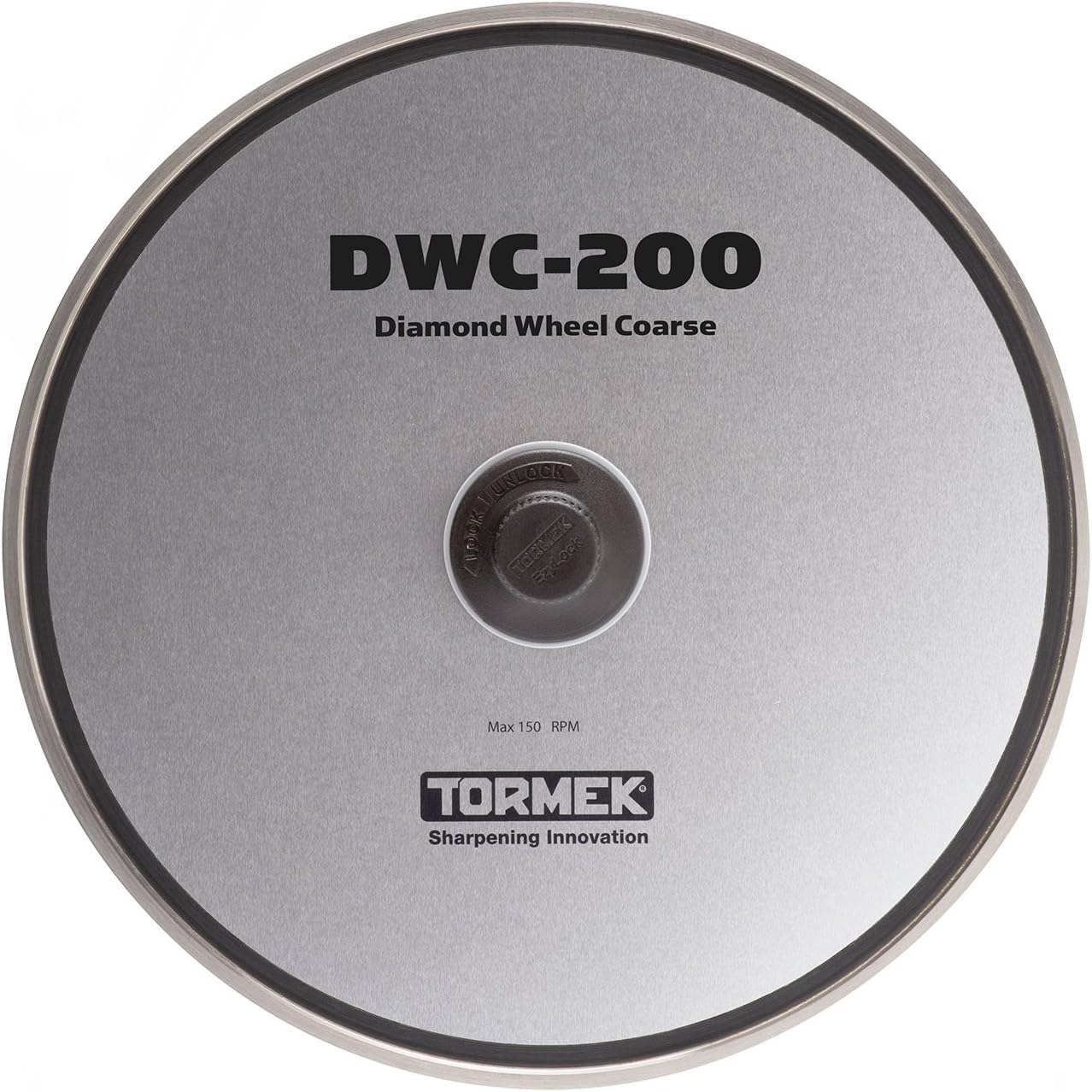

Figure 3.1: The Tormek DWC-200 Coarse Grit Diamond Wheel. This wheel is designed for rapid material removal to quickly repair dull or damaged edges on knives.

The DWC-200 wheel comes with ACC-150 Anti-Corrosion Concentrate, which should be used with water during the sharpening process to prevent corrosion and optimize performance.

4. Setup

Follow these steps to properly install the DWC-200 diamond wheel on your Tormek T-2 sharpening machine:

- Ensure the Tormek T-2 machine is turned off and unplugged from the power outlet.

- Carefully remove any existing sharpening wheel from the T-2 machine according to its instruction manual.

- Align the DWC-200 diamond wheel with the shaft on the T-2 machine and slide it into place. Ensure it is seated securely.

- Fasten the wheel using the retaining nut or mechanism provided with the T-2 machine, ensuring it is tightened sufficiently but not overtightened.

- Fill the water trough of the T-2 machine with water and add the appropriate amount of ACC-150 Anti-Corrosion Concentrate as per the instructions on the concentrate bottle.

Figure 4.1: The Tormek T-2 Sharpening Machine with the DWC-200 Diamond Wheel correctly installed and ready for use.

5. Operating Instructions

The DWC-200 coarse grit wheel is ideal for initial shaping and repairing heavily damaged or dull edges. Always refer to your Tormek T-2 machine's manual for detailed sharpening techniques.

- Ensure the water trough contains the water-ACC-150 mixture. The wheel should be partially submerged.

- Turn on the Tormek T-2 machine. The wheel will begin to rotate.

- Using the appropriate jig for your knife or tool, position the blade against the rotating diamond wheel at the desired sharpening angle.

- Apply light, consistent pressure and move the blade smoothly across the wheel, ensuring even material removal along the entire edge.

- Continue sharpening until the desired edge is achieved. For a finer edge, you may need to switch to a finer grit diamond wheel (e.g., DWF-200) or use a honing wheel.

- After sharpening, clean the blade and the machine thoroughly.

Figure 5.1: Demonstrating the sharpening process on the Tormek T-2 machine using the DWC-200 diamond wheel.

6. Maintenance

Proper maintenance will extend the life of your DWC-200 diamond wheel and ensure consistent performance:

- Cleaning: After each use, rinse the diamond wheel with clean water to remove any grinding residue. Do not use harsh chemicals or abrasive cleaners.

- ACC-150 Concentrate: Always use the ACC-150 Anti-Corrosion Concentrate with water during sharpening. This prevents corrosion on the wheel and ensures optimal sharpening results.

- Storage: Store the diamond wheel in a dry environment when not in use. If storing for an extended period, ensure it is clean and completely dry.

- Inspection: Periodically inspect the wheel for any signs of damage, cracks, or excessive wear. Replace the wheel if any damage is observed.

7. Troubleshooting

If you encounter issues with your DWC-200 diamond wheel, consider the following common problems and solutions:

- Poor Sharpening Performance:

- Ensure the correct amount of ACC-150 concentrate is mixed with water.

- Verify the blade angle is correctly set on the T-2 machine's jig.

- Check if the wheel surface is clean and free of debris.

- Excessive Vibration/Noise:

- Ensure the diamond wheel is properly seated and secured on the T-2 machine's shaft.

- Check for any foreign objects caught between the wheel and the machine.

- Rust Spots on Wheel:

- This indicates insufficient use of ACC-150 Anti-Corrosion Concentrate or improper drying after use. Ensure proper concentration and dry the wheel thoroughly after each use.

If problems persist, consult the Tormek T-2 machine's manual or contact Tormek customer support.

8. Specifications

| Attribute | Value |

|---|---|

| Model Number | TOR-DWC200 (DWC-200) |

| Grit Type | Coarse |

| Grit Number | 360 |

| Diameter | 200 mm (8 inches) |

| Material | Diamond, Metal |

| Compatible Devices | Tormek T-2 Sharpening Machine |

| Item Weight | 3.3 pounds |

| Included Components | 1 diamond wheel, ACC-150 Anti-Corrosion Concentrate |

9. Warranty and Support

For detailed warranty information regarding your Tormek DWC-200 Coarse Grit Diamond Wheel, please refer to the official Tormek website or the documentation provided with your Tormek T-2 sharpening machine.

If you require technical support, have questions about product usage, or need to inquire about repairs, please contact Tormek customer service through their official channels. Contact information can typically be found on the Tormek website or in the T-2 machine's manual.

Tormek Official Website: www.tormek.com