Introduction

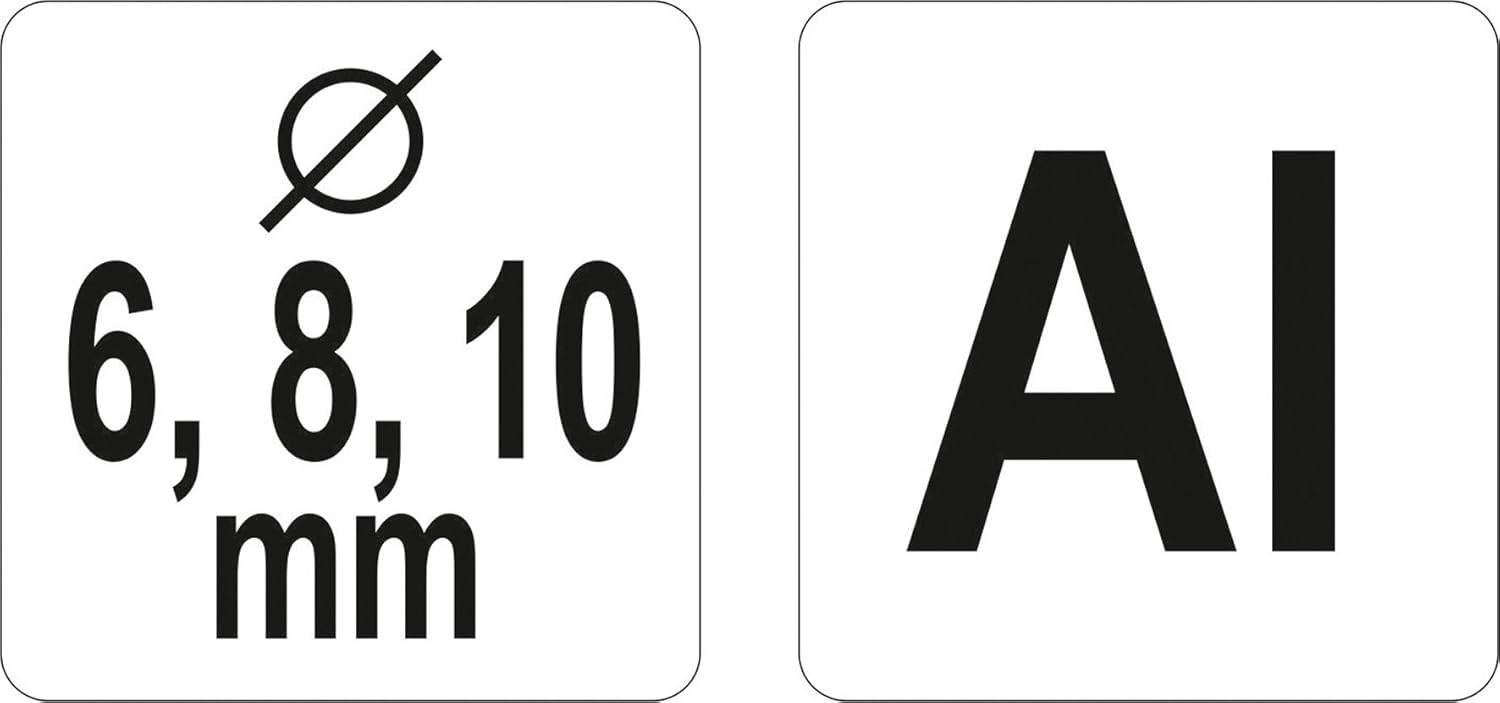

The Yato YT-44120 Dowel Jig is a precision tool designed to assist in creating accurate and strong wooden dowel joints. Constructed from durable aluminum, this self-centering jig simplifies the process of drilling perfectly aligned holes for 6mm, 8mm, and 10mm wooden dowels. It is an essential tool for woodworking projects requiring precise joinery.

Safety Information

Always observe basic safety precautions when using hand tools. Failure to do so may result in injury or damage to the tool or workpiece.

- Wear appropriate personal protective equipment (PPE), including safety glasses, to protect against flying debris.

- Ensure your workpiece is securely clamped before drilling to prevent movement.

- Use sharp drill bits appropriate for the material and dowel size.

- Keep hands and fingers clear of the drilling area.

- Do not force the drill; allow the drill bit to do the work.

- Store the tool in a clean, dry place when not in use.

Package Contents

Verify that all components are present upon opening the package:

- Yato YT-44120 Dowel Jig (Main Unit)

- Mounting Sleeves (for 6mm, 8mm, 10mm drill bits)

- Centering Sleeves

- Adjustable Stop/Fence

Figure 1: The Yato YT-44120 Dowel Jig shown with its various included components, including the main red aluminum body, brass knobs, and different sized drill guide sleeves.

Setup

Before beginning your project, ensure the dowel jig is properly set up for your specific needs.

- Select Drill Guide Sleeves: Choose the appropriate mounting sleeves (6mm, 8mm, or 10mm) that match the diameter of the wooden dowels you intend to use. Insert them into the designated holes on the jig.

Figure 2: Top view of the dowel jig, illustrating the three drill guide holes where sleeves are inserted.

- Adjust the Self-Centering Mechanism: The jig is designed to self-center on the edge of your workpiece. Place the jig onto the edge of the wood. The two main clamping arms will automatically adjust to center the drill guides.

Figure 3: Angled view of the dowel jig, highlighting its self-centering design for easy alignment on wood edges.

- Set the Adjustable Stop: For repeatable hole placement, use the adjustable stop. Loosen the brass knob on the sliding arm, position the stop at the desired distance from the drill guide, and tighten the knob securely. This ensures consistent hole depth and spacing.

Operating Instructions

Follow these steps for precise dowel hole drilling:

- Secure the Workpiece: Ensure your wooden workpiece is firmly clamped to a stable surface.

- Position the Jig: Place the Yato YT-44120 Dowel Jig onto the edge of the workpiece where you intend to drill the dowel holes. The self-centering arms will automatically align the drill guides.

- Clamp the Jig: For optimal precision, it is highly recommended to secure the jig to the workpiece using a one-hand clamp or similar clamping device. This prevents any movement during drilling.

- Drill the Holes: Insert the appropriate drill bit (matching the chosen sleeve size) into your drill. Align the drill bit with the selected drill guide hole on the jig. Begin drilling slowly, applying steady pressure. Allow the drill bit to cut cleanly through the wood.

- Clear Debris: Periodically remove sawdust and chips to ensure clear visibility and prevent clogging.

- Repeat as Needed: Reposition the jig and repeat the drilling process for all necessary dowel holes. The adjustable stop will help maintain consistent spacing.

Maintenance

Proper maintenance will extend the life and accuracy of your Yato YT-44120 Dowel Jig.

- Cleaning: After each use, wipe down the jig with a clean, dry cloth to remove sawdust and debris. Avoid using harsh chemicals that could damage the aluminum finish.

- Lubrication: Occasionally apply a light coat of machine oil to the sliding parts and brass knobs to ensure smooth operation.

- Storage: Store the jig and its accessories in a dry environment to prevent corrosion. The original packaging can be used for storage.

- Inspection: Regularly inspect the drill guide sleeves for wear or damage. Replace them if they become worn to maintain drilling accuracy.

Troubleshooting

If you encounter issues while using your dowel jig, consider the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Holes are not centered. | Jig not properly clamped; workpiece moved; worn drill guide sleeves. | Ensure the jig and workpiece are securely clamped. Inspect and replace worn sleeves. |

| Drill bit binds or struggles. | Dull drill bit; excessive pressure; sawdust buildup. | Use a sharp drill bit. Apply steady, not excessive, pressure. Clear sawdust frequently. |

| Inconsistent hole depth. | Drill bit collar/stop not set correctly; inconsistent drilling pressure. | Use a drill bit stop collar. Maintain consistent drilling pressure. |

Specifications

| Feature | Detail |

|---|---|

| Model Number | YT-44120 |

| Brand | Yato |

| Material | Aluminum (Head and Handle) |

| Color | Red |

| Dowel Diameters Supported | 6mm, 8mm, 10mm |

| Item Weight | 1.72 pounds (approx. 0.78 kg) |

| Product Dimensions | 9.37 x 4.02 x 1.89 inches (approx. 23.8 x 10.2 x 4.8 cm) |

| Included Components | Dowel Jig, Mounting Sleeves, Centering Sleeves |

Figure 4: Visual representation of supported dowel diameters (6, 8, 10 mm) and aluminum construction.

Warranty and Support

For information regarding warranty coverage, technical support, or replacement parts for your Yato YT-44120 Dowel Jig, please refer to the official Yato website or contact their customer service department. Keep your purchase receipt as proof of purchase.

Note: Specific warranty terms may vary by region and retailer.