1. Introduction

This manual provides essential information for the safe and efficient operation of your GROZ Electric Drum Pump, Model 45503. This 12V DC pump is designed for transferring various fluids from 55-gallon drums. Please read these instructions thoroughly before installation and use to ensure proper function and to prevent injury or damage.

2. Product Overview and Components

The GROZ Electric Drum Pump (Model 45503) is engineered for reliable fluid transfer. Key components include the pump motor unit, adjustable telescopic suction tube, flexible discharge hose, manual dispensing nozzle, and 12V DC power cable with crocodile clips.

Image 2.1: Detailed diagram illustrating the various components of the GROZ Electric Drum Pump, including the lift handle, on/off switch, pump outlet with swivel connection, manual dispensing nozzle, flexible corrugated hose, telescopic suction tube, SS strainer, and 3/4" (19 mm) SS spout.

- Pump Motor Unit: Houses the 12V DC brush motor and control switch.

- Telescopic Suction Tube: Adjustable from 33.5" to 49" (850mm to 1245mm) to fit various drum depths.

- Flexible Corrugated Hose: 6.6 feet (2 meters) long for extended reach.

- Manual Dispensing Nozzle: Features a 3/4" NPT stainless steel spout for controlled fluid dispensing.

- 2" Bung Adaptor: Integrated for secure mounting on 55-gallon drums.

- 12V DC Power Cable: Equipped with crocodile clips for connection to a 12V DC power source.

- Safety Features: Includes an overload protection fuse and a stainless steel inlet filter.

3. Safety Information

WARNING: Read all safety warnings and instructions. Failure to follow the warnings and instructions may result in electric shock, fire, and/or serious injury.

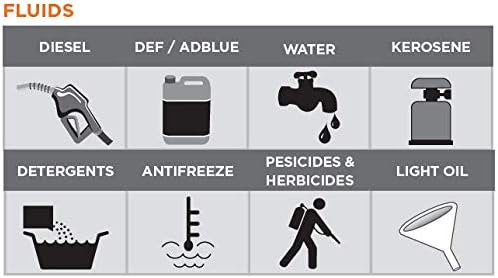

3.1 Fluid Compatibility

This pump is suitable for transferring:

- Diesel

- DEF (Diesel Exhaust Fluid) / AdBlue

- Water

- Antifreeze

- Light oils (up to 100 CST viscosity)

- Detergents

- Pesticides & Herbicides

- Kerosene

DO NOT USE WITH:

- Gasoline

- Corrosive chemicals

- Lacquer thinners

- Any material that is not compatible with the pump construction.

Image 3.1: Visual guide indicating fluids compatible with the GROZ Electric Drum Pump, including diesel, DEF, water, kerosene, detergents, antifreeze, pesticides & herbicides, and light oil.

3.2 General Safety Precautions

- Always wear appropriate personal protective equipment (PPE) such as gloves and eye protection.

- Ensure the pump is securely mounted to the drum before operation.

- Do not operate the pump if it is damaged or malfunctioning.

- Keep the work area well-ventilated.

- Disconnect power before performing any maintenance or cleaning.

- Avoid prolonged dry running of the pump.

4. Setup and Installation

Follow these steps to set up your GROZ Electric Drum Pump:

- Assemble Suction Tube: Extend the telescopic suction tube to the desired length to reach near the bottom of your drum. Secure it firmly.

- Attach Hose and Nozzle: Connect the flexible corrugated hose to the pump outlet. Attach the manual dispensing nozzle to the other end of the hose. Ensure all connections are tight to prevent leaks.

- Mount on Drum: Insert the pump's suction tube into the drum opening. The integrated 2" bung adaptor should fit directly onto standard 55-gallon drum threads. Tighten the bung adaptor to secure the pump to the drum. If your drum has buttress threads, use the provided thread converter.

- Connect Power: Connect the red crocodile clip to the positive (+) terminal of a 12V DC power source (e.g., car battery) and the black clip to the negative (-) terminal. Ensure a secure connection.

Image 4.1: The GROZ Electric Drum Pump securely mounted on a 55-gallon drum, ready for fluid transfer. The image highlights the pump's compact design and ease of installation.

5. Operating Instructions

Once the pump is installed and powered, follow these steps for operation:

- Position Nozzle: Place the dispensing nozzle into the receiving container.

- Turn On Pump: Flip the ON/OFF switch on the pump motor unit to the 'ON' position. The LED indicator will illuminate.

- Dispense Fluid: Squeeze the trigger on the manual dispensing nozzle to begin fluid flow. Release the trigger to stop the flow.

- Monitor Fluid Level: Keep an eye on the fluid level in both the drum and the receiving container to prevent spills or dry running.

- Turn Off Pump: Once dispensing is complete, release the nozzle trigger and flip the ON/OFF switch to the 'OFF' position.

- Disconnect Power: Disconnect the 12V DC power cable from the power source.

Image 5.1: A user demonstrating the operation of the GROZ Electric Drum Pump, showing the manual dispensing nozzle in use to transfer fluid into a container.

Duty Cycle: 15 minutes ON / 15 minutes OFF. Adhering to the duty cycle helps prolong pump life.

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your pump.

- Cleaning: After each use, especially when transferring corrosive or viscous fluids, rinse the pump thoroughly with clean water or a compatible cleaning agent. This prevents residue buildup and corrosion.

- Filter Inspection: Periodically inspect the stainless steel inlet filter for debris. Clean or replace if necessary to maintain proper flow and prevent pump damage.

- Hose and Nozzle: Check the hose and nozzle for any signs of wear, cracks, or blockages. Replace damaged components immediately.

- Storage: Store the pump in a clean, dry place, away from direct sunlight and extreme temperatures. Ensure all fluid is drained before storage.

7. Troubleshooting

If you encounter issues with your GROZ Electric Drum Pump, refer to the following table:

| Problem | Possible Cause | Solution |

|---|---|---|

| Pump does not turn on | No power to pump; Blown fuse; Faulty switch | Check 12V DC power connection; Inspect and replace fuse if blown; Contact support if switch is faulty. |

| Low flow rate or no fluid dispensed | Inlet filter clogged; Suction tube not fully submerged; Air leak in suction line; Viscous fluid; Hose kinked or blocked | Clean inlet filter; Adjust suction tube depth; Check all connections for tightness; Ensure fluid viscosity is within limits (max 100 CST); Straighten hose or clear blockage. |

| Pump runs but no fluid is dispensed | Pump not primed; Air in system; Suction tube above fluid level | Ensure pump is submerged in fluid; Check for air leaks; Adjust suction tube. |

| Fluid leaks from connections | Loose connections; Damaged seals/gaskets | Tighten all hose and bung connections; Inspect and replace any damaged seals or gaskets. |

8. Specifications

Technical specifications for the GROZ Electric Drum Pump (Model 45503):

- Model: 45503

- Motor Type: DC Brush Motor (5 Pole)

- Power Source: 12V DC (Corded Electric)

- DC Power Cable: 4m long with Crocodile Clips

- Max. Viscosity of Media: 100 cSt

- Operating Temperature: 5°C to 40°C (41°F to 104°F)

- Suction Tube Length: Adjustable 33.5" - 49" (850mm - 1245mm)

- Hose Length: 6.6 Feet (2 meters)

- Outlet Connection Size: 0.75 Inches

- Inlet Connection Size: 2 Inches

- Body Material: Stainless Steel, Plastic

- Item Weight: 7.09 pounds

- Package Dimensions: 46 x 9.6 x 5.5 inches

- Duty Cycle: 15 minutes ON / 15 minutes OFF

- Certifications: CE, UL, cUL

Image 8.1: A table detailing the technical specifications of the GROZ Electric Drum Pump, including motor type, power cable, maximum viscosity, and operating temperature.

9. Warranty and Support

The GROZ Electric Drum Pump (Model 45503) is covered by a Manufacturer Warranty. For specific warranty terms, conditions, and duration, please refer to the documentation included with your product or contact GROZ customer support directly.

For technical assistance, spare parts, or any inquiries not covered in this manual, please contact GROZ customer service through their official website or authorized distributors.