1. Introduction

This manual provides essential information for the proper installation, operation, and maintenance of the Unknown Brand Ink Pump, Model PRO-031. This component is designed for use with specific Roland SP and SJ series printers to ensure efficient ink delivery. Adherence to these instructions will help maintain optimal performance and longevity of the ink pump.

2. Product Overview

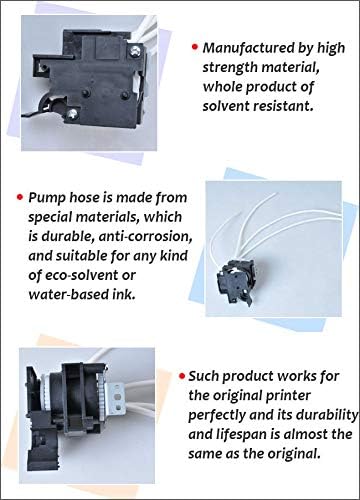

The Ink Pump (Model PRO-031) is a critical component in the ink delivery system of compatible Roland printers. It is engineered to be solvent-resistant, making it suitable for use with various eco-solvent or water-based inks. Its construction emphasizes durability and anti-corrosion properties to ensure reliable performance over time.

Figure 2.1: Close-up of the Ink Pump, showing the main body and connected tubes.

Figure 2.2: The Ink Pump with its integrated tubing, ready for installation.

Figure 2.3: Key features of the Ink Pump, highlighting its material strength, solvent resistance, and durable hose.

3. Compatibility

This ink pump is compatible with the following Roland printer models:

- Roland SJ-740

- Roland SJ-540

- Roland SJ-645 EX

- Roland SJ-745 EX

- Roland SJ-1000

- Roland SJ-1045 EX

- Roland SJ-545 EX

- Roland SP-300

- Roland SP-300V

- Roland SP-540

- Roland SP-540V

Ensure your printer model is listed above before proceeding with installation.

4. Setup and Installation

Installation of printer components should ideally be performed by a qualified technician. Incorrect installation can lead to damage to the printer or the component.

- Power Off: Before beginning any installation, ensure the printer is completely powered off and disconnected from the main power supply.

- Access: Carefully open the printer's access panels to locate the existing ink pump. Refer to your printer's service manual for specific access instructions.

- Removal: Disconnect all ink tubes and electrical connectors from the old ink pump. Note the orientation and connection points for reassembly. Remove any mounting screws or clips securing the old pump.

- Installation: Position the new Ink Pump (Model PRO-031) in the designated location. Secure it using the appropriate mounting hardware.

- Connections: Reconnect the ink tubes to the new pump, ensuring a secure and leak-free fit. Verify that each tube is connected to its correct port. Reconnect any electrical connectors.

- Inspection: Visually inspect all connections and mounting points to ensure everything is correctly installed and secured.

- Power On: Close all printer access panels. Reconnect the printer to the power supply and power it on.

- Test: Perform a test print or initiate a cleaning cycle to verify proper ink flow and pump function.

5. Operating Principles

The ink pump facilitates the movement of ink from the cartridges or bulk ink system to the print heads. It operates in conjunction with the printer's control system to maintain consistent ink pressure and flow, which is essential for high-quality printing. During cleaning cycles, the pump also assists in drawing waste ink through the capping station to prevent clogs and maintain print head health.

6. Maintenance

Regular maintenance helps extend the lifespan of the ink pump and ensures consistent printer performance.

- Regular Inspection: Periodically inspect the ink pump and its tubing for any signs of wear, cracks, or leaks. Address any issues promptly.

- Cleanliness: Keep the area around the ink pump clean and free from ink spills or dust accumulation.

- Ink Compatibility: Always use inks that are compatible with your printer and the solvent-resistant properties of this pump. Using incompatible inks can lead to premature wear or failure.

- Professional Service: For any complex maintenance or repair, consult a qualified printer technician.

7. Troubleshooting

If you experience issues related to ink delivery, consider the following basic troubleshooting steps:

- No Ink Flow: Check all ink tube connections to ensure they are secure and not kinked or blocked. Verify that ink cartridges or bulk ink systems have sufficient ink.

- Weak Ink Flow: This could indicate a partial blockage or a pump that is not operating at full efficiency. Check for air bubbles in the ink lines.

- Unusual Noises: If the pump makes unusual noises, it may indicate a mechanical issue. Power off the printer and inspect the pump for any visible obstructions or damage.

- Error Messages: Refer to your printer's user manual for specific error codes related to the ink system.

For persistent problems, professional diagnosis and repair are recommended.

8. Specifications

| Specification | Detail |

|---|---|

| Product Name | Ink Pump |

| Model Number | PRO-031 |

| Brand | Unknown |

| Manufacturer | KD-Tec |

| Applicable Printer Models | Roland SJ-740 / SJ-540 / SJ-645 EX / SJ-745 EX / SJ-1000 / SJ-1045 EX / SJ-545 EX, Roland SP-300 / SP-300V / SP-540 / SP-540V |

| Product Size (Approx.) | 60mm x 60mm x 50mm |

| Net Weight (Approx.) | 75g (2.65 ounces) |

| Packing Size (Approx.) | 90mm x 80mm x 70mm |

| Packing Weight (Approx.) | 80g (2.82 ounces) |

| UPC | 756155144709 |

| Material Properties | Solvent Resistant, Anti-corrosion |

9. Warranty Information

Specific warranty terms for this product are typically provided by the seller at the time of purchase. Please retain your proof of purchase and contact the seller directly for any warranty-related inquiries.

10. Support

For technical assistance or further questions regarding the installation or operation of this ink pump, please contact the vendor or a qualified printer service technician. Always refer to your printer's official documentation for comprehensive service and support information.