1. Product Overview

This manual provides essential information for the installation, operation, and maintenance of your DB Electrical Aftermarket Starter. This starter is designed as a high-quality replacement component for various vehicle models, ensuring reliable engine cranking performance.

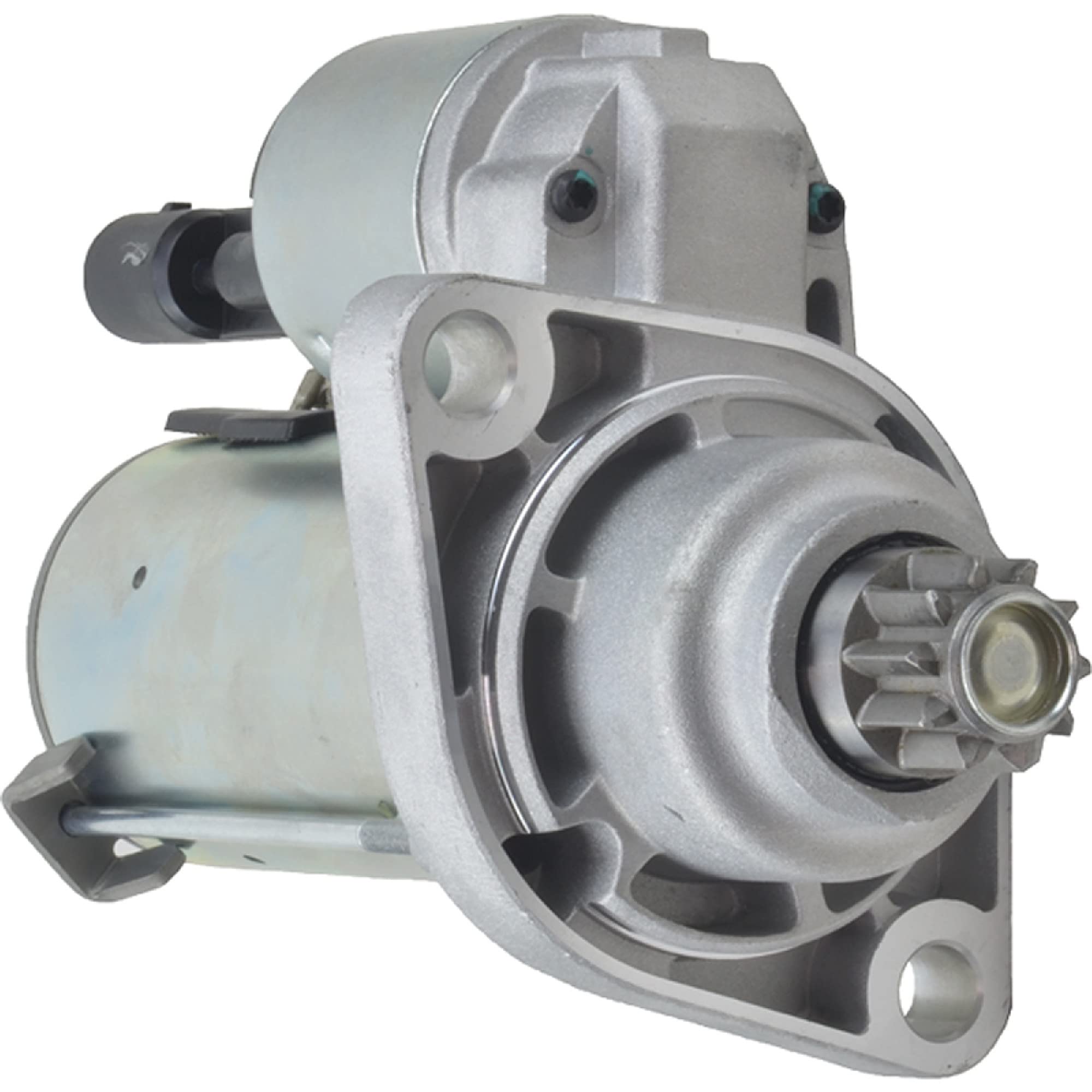

Image: The DB Electrical Aftermarket Starter, a 12V, 10-tooth, counter-clockwise rotation unit, designed for efficient engine starting. This image displays the complete starter assembly, highlighting its robust construction and key components.

2. Key Features

- Specifications: Voltage: 12V, Rotation: Counter-Clockwise (CCW), Teeth: 10, Power: 1.1 Kilowatts (KW), Type: Permanent Magnet Gear Reduction (PMGR).

- OEM Compatibility: Built to meet or exceed Original Equipment Manufacturer (OEM) specifications for a precise fit and reliable performance.

- Aftermarket Quality: A new aftermarket starter, offering a cost-effective alternative without compromising on quality.

- Cross-Reference: Compatible with various OEM and aftermarket part numbers including CARGO: 113773, DIXIE: S-6560, LESTER: 17970, VOLKSWAGEN: 02M-911-021B, 02M-911-021BX, 02M-911-023M, and Arrowhead: SVA0026.

3. Vehicle Compatibility

This aftermarket starter is compatible with a range of Audi and Volkswagen vehicles. Please verify your vehicle's specific requirements before installation.

- AUDI:

- Q3 2.0L: 2015 - 2017

- TT 2.0L: 2008 - 2010

- VOLKSWAGEN:

- BEETLE 2.0L: 2012 - 2013

- CC 2.0L: 2012 - 2017

- EOS 2.0L: 2007 - 2009

- GOLF 2.0L: 2012 - 2014

- GTI 2.0L: 2006 - 2014

- JETTA 1.8L: 2014

- PASSAT 2.0L: 2006 - 2009

- TIGUAN 2.0L: 2010 - 2017

4. Setup and Installation

Installation of an automotive starter requires mechanical knowledge and specialized tools. It is highly recommended that installation be performed by a certified automotive technician to ensure proper function and safety.

Safety Precautions:

- Always disconnect the vehicle's battery (negative terminal first) before beginning any electrical work.

- Ensure the vehicle is on a stable, level surface and properly supported with jack stands if lifted.

- Wear appropriate personal protective equipment (PPE), including safety glasses and gloves.

- Allow the engine and exhaust system to cool down before working to prevent burns.

Installation Steps (General Guidance):

- Preparation: Disconnect the battery. Locate the existing starter motor.

- Removal: Disconnect electrical connections (battery cable, solenoid wire) from the old starter. Remove mounting bolts and carefully extract the old starter.

- Inspection: Inspect the flywheel/flexplate teeth for damage. Clean the mounting surface.

- Installation: Position the new DB Electrical starter and secure it with mounting bolts, tightening to manufacturer specifications.

- Connections: Reconnect the electrical wires to the new starter, ensuring all connections are clean and tight.

- Final Steps: Reconnect the vehicle's battery. Perform a functional test.

Refer to your vehicle's specific service manual for detailed, model-specific installation instructions and torque specifications.

5. Operating Instructions

The starter motor is an integral part of your vehicle's starting system. Its primary function is to crank the engine to initiate combustion. Operation is automatic upon turning the ignition key to the "START" position or pressing the start button.

- Ensure the vehicle is in Park (P) for automatic transmissions or Neutral (N) with the clutch depressed for manual transmissions.

- Turn the ignition key to the "START" position and hold it until the engine starts. Do not crank the engine for more than 10-15 seconds at a time to prevent overheating the starter.

- If the engine does not start on the first attempt, wait at least 30 seconds before attempting to crank again to allow the starter to cool.

6. Maintenance

The DB Electrical Aftermarket Starter is designed for durability and minimal maintenance. However, regular vehicle maintenance practices contribute to its longevity.

- Battery Health: Ensure your vehicle's battery is in good condition and fully charged. A weak battery can strain the starter motor.

- Electrical Connections: Periodically check the battery cables and starter connections for corrosion or looseness. Clean and tighten as necessary.

- Engine Condition: A well-maintained engine that starts easily reduces the workload on the starter.

7. Troubleshooting

If you experience issues with your vehicle's starting system, consider the following common scenarios. For complex issues, consult a qualified automotive technician.

Common Issues:

- No Crank / No Click:

- Check battery terminals for corrosion or looseness.

- Verify battery charge level.

- Inspect starter solenoid wire connection.

- Check vehicle's fuses related to the starting system.

- Slow Crank / Weak Crank:

- Indicates a weak battery or poor battery cable connections.

- Could also indicate excessive resistance in the starter circuit or an issue with the starter itself.

- Clicking Sound, No Crank:

- Often a sign of a low battery or a faulty starter solenoid.

Always diagnose the root cause of the problem before replacing components. A faulty battery or wiring can mimic starter failure.

8. Specifications

| Attribute | Value |

|---|---|

| Model | 410-40032 |

| Voltage | 12 Volts |

| Wattage / Power | 1.1 KW |

| Rotation | CCW (Counter-Clockwise) |

| Teeth | 10 |

| Type | PMGR (Permanent Magnet Gear Reduction) |

| Item Weight | 1 pounds (approx. 16 ounces) |

| Product Dimensions (L x W x H) | 10.25 x 5.5 x 4.75 inches |

| Manufacturer | DB Electrical |

| OEM Part Number | 410-40032 |

| UPC | 711811741272 |

9. Warranty and Support

Warranty Information:

This DB Electrical Aftermarket Starter is backed by a 1-year warranty from the date of purchase. This warranty covers defects in materials and workmanship under normal use. Please retain your proof of purchase for warranty claims.

Customer Support:

For technical assistance, troubleshooting, or warranty inquiries, please contact DB Electrical customer support. You can find more information and contact details by visiting the official DB Electrical store on Amazon: DB Electrical Store.