1. Introduction and Overview

Welcome to the user manual for your ATMOS DC GSE series wood gasifier. This manual provides essential information for the safe and efficient operation, installation, and maintenance of your heating system. The ATMOS wood gasifiers are designed for clean and highly efficient combustion of wood, offering an environmentally friendly and economical heating solution.

The ATMOS GSE series is renowned for its excellent emission values and optimal price-performance ratio, making it a popular choice in Germany, often supported by government incentives like BAFA. The advanced design, including a patented V-shaped ceramic lining, ensures complete combustion and a long service life for the appliance.

Image 1.1: The ATMOS DC-40-GSE Wood Gasifier. This image shows the front view of the blue and grey wood gasifier with control panel at the top and three access doors.

2. Safety Information

Please read all safety instructions carefully before operating the appliance. Failure to follow these instructions can result in property damage, serious injury, or death.

- Professional Installation: This appliance must be installed by a qualified and certified professional in accordance with all local and national building codes and regulations.

- Carbon Monoxide Hazard: Wood gasifiers produce carbon monoxide, an odorless and colorless gas that can be fatal. Ensure proper ventilation and install carbon monoxide detectors.

- Fire Hazard: Keep combustible materials at a safe distance from the appliance. Do not store flammable liquids or materials near the wood gasifier.

- Hot Surfaces: The exterior surfaces of the wood gasifier become extremely hot during operation. Avoid contact and keep children and pets away.

- Fuel Type: Only use dry, untreated wood as fuel. Do not burn trash, plastics, treated wood, or other unauthorized materials.

- Ash Disposal: Dispose of ashes in a non-combustible container with a tight-fitting lid, away from combustible materials.

3. Product Features

The ATMOS DC GSE series wood gasifiers are designed with advanced features to ensure efficient and clean heating:

- High Efficiency: Optimized combustion process for maximum heat extraction from wood.

- Low Emissions: Meets stringent emission standards, including BAFA requirements, contributing to cleaner air.

- Durable Construction: Built with robust materials for a long operational lifespan.

- Patented Ceramic Lining: Features a V-shaped ceramic lining in the filling chamber, patented by ATMOS, which ensures optimal sliding of fuel and complete combustion.

- Fuel Versatility: Models DC18GSE and DC22GSE accommodate wood logs up to 38 cm (approx. 15 inches). Larger models (DC25GSE, DC30GSE, DC40GSE, DC50GSE) can handle wood logs up to 58 cm (approx. 23 inches).

Image 3.1: BAFA Support Badge. This badge indicates eligibility for government funding (2,000 €) for the ATMOS GSE series.

Image 3.2: BlmSchV II Compliance Badge. This badge signifies that the ATMOS series meets the requirements of the German Federal Immission Control Ordinance (BlmSchV) Level II.

4. Setup and Installation

The installation of the ATMOS wood gasifier is a complex process that requires specialized knowledge and adherence to strict safety and building regulations. It must be performed by a certified heating technician.

4.1 Pre-Installation Checks

- Location: Ensure the installation location is suitable, with adequate space for maintenance and fuel storage.

- Chimney/Flue: Verify that the chimney or flue system is correctly sized, in good condition, and compliant with local regulations for solid fuel appliances.

- Ventilation: Ensure sufficient air supply for combustion and proper ventilation of the boiler room.

- Buffer Tank: An appropriately sized buffer tank is essential for efficient operation and heat storage.

4.2 Connection to Heating System

The wood gasifier must be correctly integrated into your existing or new heating system, including connections for heating circuits, domestic hot water, and safety devices. This typically involves:

- Hydraulic connections to the buffer tank and heating circuits.

- Electrical connections for controls and pumps.

- Installation of safety valves, expansion vessels, and pressure gauges.

Refer to the detailed installation diagrams provided with your specific model for precise connection instructions. Always consult with your certified installer for any questions regarding setup.

5. Operating Instructions

Operating your ATMOS wood gasifier involves a few key steps to ensure efficient and safe heating.

5.1 Fueling the Boiler

- Open the loading door.

- Load the combustion chamber with dry wood logs. Ensure the wood is seasoned (moisture content below 20%) for optimal combustion and minimal emissions.

- Close the loading door securely.

5.2 Ignition

- Place kindling and a few smaller pieces of wood on the grate in the lower combustion chamber.

- Ignite the kindling.

- Once the fire is established, the gasification process will begin, and the primary and secondary air will be supplied automatically or manually depending on your model.

5.3 Maintaining Combustion

The wood gasifier is designed for long burn times. Monitor the control panel for temperature and operational status. Refuel as needed based on heat demand and the size of your heated area.

5.4 Refueling Frequency Guidelines

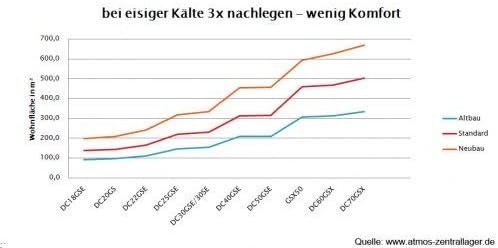

The following charts provide general guidelines for refueling frequency based on the heated living area (Wohnfläche in m²) and building type (Altbau - old building, Standard, Neubau - new building). These are approximations and actual frequency may vary based on insulation, outdoor temperature, and user preferences.

Image 5.1: Refueling Frequency - 1x per day for high comfort in very cold conditions. This chart shows the heated living area (Wohnfläche in m²) on the Y-axis against different ATMOS boiler models on the X-axis, with three lines representing old buildings, standard buildings, and new buildings, indicating the area that can be heated with one refueling per day.

Image 5.2: Refueling Frequency - 2x per day for good comfort in very cold conditions. This chart shows the heated living area (Wohnfläche in m²) on the Y-axis against different ATMOS boiler models on the X-axis, with three lines representing old buildings, standard buildings, and new buildings, indicating the area that can be heated with two refuelings per day.

Image 5.3: Refueling Frequency - 3x per day for less comfort in very cold conditions. This chart shows the heated living area (Wohnfläche in m²) on the Y-axis against different ATMOS boiler models on the X-axis, with three lines representing old buildings, standard buildings, and new buildings, indicating the area that can be heated with three refuelings per day.

6. Maintenance

Regular maintenance is crucial for the efficient and safe operation of your ATMOS wood gasifier. Always ensure the appliance is cool before performing any maintenance.

6.1 Daily/Weekly Maintenance

- Ash Removal: Regularly remove ash from the ash pan and combustion chamber. The frequency depends on usage and fuel type. Ensure ashes are completely cool before disposal.

- Inspect Combustion Chamber: Check the ceramic lining and grate for any damage or excessive buildup.

6.2 Monthly/Seasonal Maintenance

- Flue Pipe Cleaning: Clean the flue pipe connecting the boiler to the chimney to prevent creosote buildup.

- Heat Exchanger Cleaning: Clean the heat exchanger surfaces to maintain optimal heat transfer efficiency.

- General Inspection: Check all seals, gaskets, and moving parts for wear and tear.

6.3 Annual Professional Servicing

It is highly recommended to have your ATMOS wood gasifier inspected and serviced annually by a qualified technician. This includes a thorough cleaning, inspection of all components, and adjustment of settings for optimal performance and safety.

7. Troubleshooting

This section addresses common issues you might encounter with your wood gasifier. For complex problems, always contact a qualified service technician.

7.1 Poor Combustion / Low Heat Output

- Check Fuel: Ensure wood is dry and properly seasoned. Wet wood burns inefficiently and produces more smoke.

- Air Supply: Verify that primary and secondary air inlets are not blocked and are correctly adjusted.

- Ash Buildup: Excessive ash in the combustion chamber or ash pan can restrict airflow. Clean thoroughly.

- Chimney Draft: Ensure adequate chimney draft. Blockages or insufficient chimney height can impair combustion.

7.2 Excessive Smoke

- Wet Wood: The most common cause. Use only dry wood.

- Insufficient Air: Ensure proper air supply settings.

- Flue/Chimney Blockage: Check for creosote buildup or other obstructions in the flue pipe or chimney.

- Improper Loading: Overloading the chamber or improper stacking of wood can hinder gasification.

7.3 Boiler Not Reaching Desired Temperature

- Fuel Quality/Quantity: Ensure sufficient dry wood is loaded.

- System Pressure: Check the pressure in the heating system. Low pressure can indicate a leak.

- Pump Malfunction: Verify that circulation pumps are operating correctly.

- Control Settings: Review the boiler's control settings and thermostat settings.

8. Specifications

Key technical specifications for the ATMOS DC-40-GSE Wood Gasifier:

| Specification | Value |

|---|---|

| Manufacturer | Atmos |

| Item Number | DC-40-GSE |

| Item Weight | 380 kg (approx. 837.76 lbs) |

| Size | DC-40-GSE 40 kW Power |

| Exterior Finish | Wood (referring to wood-burning capability) |

| First Available Date | 5 December 2020 |

9. Warranty and Support

For information regarding the warranty period and terms for your ATMOS wood gasifier, please refer to the warranty card included with your purchase or contact your authorized dealer. Keep your proof of purchase for warranty claims.

For technical support, spare parts, or professional servicing, please contact your local ATMOS dealer or a certified heating technician. Do not attempt to repair the appliance yourself, as this may void the warranty and pose safety risks.