Product Overview

The Barnes 4WD U-Bolt, measuring 5/8" X 4" X 10", is engineered for robust performance in automotive suspension systems, specifically designed for applications such as AAM 11.5, Dana 80, or Dana 70 HD axles. Unlike standard U-bolts, this component is meticulously manufactured to ensure optimal strength and reliability.

Key features include:

- Constructed from cold-drawn 1541 alloy, stress-relieved to achieve Grade 8 strength without excessive hardness.

- Features 5/8"-18 fine threads, manufactured with a smooth rolled thread for precise engagement.

- Accompanied by hardened Hi-Nuts and thick washers with sharp cut threads, ensuring a secure and lasting connection.

- Designed to stretch slightly upon tightening, maintaining proper fastener tightness.

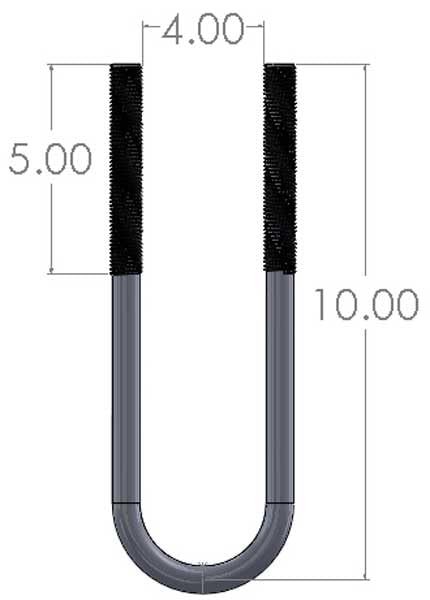

Figure 1: Front view of the Barnes 4WD U-Bolt with nuts and washers. This image illustrates the overall shape and components of the U-bolt.

Safety Information

Always prioritize safety when working with automotive components. Failure to follow safety guidelines can result in serious injury or damage to property.

- Wear appropriate personal protective equipment, including safety glasses and gloves.

- Ensure the vehicle is properly supported on jack stands or a lift before beginning any work.

- Use only the correct tools for installation and removal.

- If you are unsure about any part of the installation process, consult a qualified automotive professional.

- Keep hands and clothing clear of moving parts and pinch points.

Setup and Installation

Proper installation of the U-bolt is critical for the safety and performance of your vehicle's suspension system. Adhere strictly to the torque specifications and guidelines provided.

Components

- Barnes 4WD U-Bolt (5/8" X 4" X 10")

- Hardened Hi-Nuts (5/8"-18 thread)

- Thick Washers

Installation Procedure

- Ensure all mating surfaces on the axle and leaf spring assembly are clean and free of debris or corrosion.

- Position the U-bolt around the axle and leaf spring pack, ensuring proper alignment with the mounting plate holes.

- Place the thick washers over the threaded ends of the U-bolt.

- Thread the hardened Hi-Nuts onto the U-bolt ends. Hand-tighten initially to ensure proper thread engagement.

- Using a torque wrench, tighten the Hi-Nuts to a specification of 150 foot-pounds. Tighten in a cross-pattern to ensure even clamping force.

- Important: Never use an impact gun to tighten these U-bolts, as this can lead to over-tightening, thread damage, or premature failure.

- Warning: U-bolts should never be reused. The threads stretch during initial tightening to maintain proper tension. Reusing a U-bolt can lead to cross-threading, insufficient clamping force, and potential failure.

Figure 2: Dimensional drawing of the Barnes 4WD U-Bolt. This diagram provides key measurements including leg length, thread length, and overall width, crucial for fitment verification.

Operating Principles

Once installed and properly torqued, the Barnes 4WD U-bolt functions by clamping the leaf spring assembly securely to the vehicle's axle. The design, including the specific alloy and rolled threads, allows for a controlled stretch of the U-bolt during tightening. This stretching ensures that the fastener maintains consistent tension, preventing loosening under dynamic loads experienced during vehicle operation. This secure connection is vital for maintaining axle alignment and the integrity of the suspension system.

Maintenance

The Barnes 4WD U-bolt is designed for long-term reliability when installed correctly. The primary maintenance consideration is its non-reusability.

- Do Not Reuse: As stated in the installation section, U-bolts should never be reused after being tightened and removed. The initial tightening process causes a permanent stretch in the threads, which compromises their ability to hold proper torque if reinstalled.

- Periodic Inspection: While designed to maintain tightness, it is good practice to periodically inspect all suspension fasteners during routine vehicle maintenance. Look for any signs of damage, corrosion, or loosening. If a U-bolt appears loose or damaged, it must be replaced with a new one.

Troubleshooting

Most issues related to U-bolts stem from improper installation or reuse.

Loose Fasteners

Symptom: U-bolts feel loose, or there is excessive play in the axle-to-leaf spring connection.

Possible Causes:

- Incorrect torque applied during installation (under-torqued).

- Use of an impact gun, which can lead to inconsistent or over-torquing, potentially damaging threads.

- Reusing a U-bolt that has already been stretched.

Solution: If U-bolts are loose, they must be replaced with new ones and torqued to the specified 150 foot-pounds using a calibrated torque wrench. Do not attempt to re-torque old U-bolts.

Cross-threading or Damaged Threads

Symptom: Nuts do not thread smoothly, or threads appear stripped/damaged.

Possible Cause:

- Attempting to reuse a U-bolt.

- Improper initial thread engagement.

Solution: Immediately replace any U-bolt or nut with damaged threads. Do not attempt to force damaged threads, as this will compromise the integrity of the connection.

Specifications

| Property | Value |

|---|---|

| Product Dimensions | 12 x 2.5 x 1 inches |

| Item Weight | 2.5 Pounds |

| Material | Medium Carbon Steel |

| Grade Rating | Grade 8 Equivalent |

| Thread Size | 5/8 inches-18 |

| Exterior Finish | Unfinished |

| Manufacturer | Barnes 4WD |

| ASIN | B01N9404HN |

Support and Warranty

For technical support, product inquiries, or assistance with your Barnes 4WD U-bolt, please contact Barnes 4WD directly. While specific warranty details are not provided in this manual, Barnes 4WD is committed to the quality of its products.

Please refer to the official Barnes 4WD website or your purchase documentation for the most current warranty information and contact details.