1. Introduction

This manual provides comprehensive instructions for the safe and efficient operation, control, and maintenance of the J I Case W11B Loader. It is an essential resource for operators and owners, designed to ensure proper usage and longevity of the equipment.

This document is a high-quality reproduction of the original equipment manufacturer's (OEM) manual, featuring clear illustrations and detailed text. It is printed with heavy stock covers and is durably bound, making it suitable for use in various environments, including workshops and field operations.

Figure 1.1: Front cover of the J I Case W11B Loader Operators Manual, showing the title and Case branding.

2. Product Overview: J I Case W11B Loader

The J I Case W11B Loader is a robust piece of agricultural and construction machinery designed for heavy-duty tasks. This section provides a visual representation of the loader, highlighting its general appearance and key components.

Figure 2.1: A black and white photograph of the J I Case W11B Loader, showcasing its front-end loader arm and bucket, operator cabin, and large wheels, indicative of its heavy machinery classification.

3. Safety Information

Operating heavy machinery like the W11B Loader requires strict adherence to safety protocols to prevent accidents and injuries. Always read and understand all safety warnings and instructions before operating, maintaining, or transporting the machine.

- Ensure all safety guards and devices are in place and functioning correctly.

- Wear appropriate personal protective equipment (PPE) at all times.

- Never operate the loader under the influence of alcohol or drugs.

- Be aware of your surroundings and keep bystanders clear of the operating area.

- Perform daily pre-operation checks as outlined in the maintenance section.

Refer to the full manual for detailed safety guidelines specific to the J I Case W11B Loader.

4. Operation and Controls

This section covers the fundamental aspects of operating the J I Case W11B Loader, including the identification and function of various controls. Proper understanding of these controls is crucial for efficient and safe operation.

4.1 Starting and Stopping the Engine

Detailed procedures for starting the engine under various conditions, including cold weather, are provided. It also covers the correct methods for safely stopping the engine and parking the machine.

4.2 Operator Controls

Familiarize yourself with the instrument panel, foot pedals, auxiliary steering, and various levers such as the bucket control lever, lift arm control lever, and direction control lever. Each control's function and proper usage are explained to ensure precise machine handling.

- Instrument Panel: Displays critical information such as engine temperature, oil pressure, and fuel levels.

- Foot Pedals: Control braking and acceleration.

- Loader Controls: Levers for raising, lowering, tilting, and dumping the loader bucket.

- Transmission Controls: For selecting forward, reverse, and different speed ranges.

5. Maintenance

Regular maintenance is vital for the longevity and optimal performance of your J I Case W11B Loader. This section outlines key maintenance procedures.

5.1 Cooling System Maintenance

Proper cooling system function prevents engine overheating. This involves regular cleaning and fluid checks.

- Draining and Flushing: Periodically drain and flush the cooling system to remove contaminants.

- Coolant Level Check: Ensure the coolant level is maintained at the full mark in the reservoir.

- Radiator Cap: Inspect and properly secure the radiator cap.

Figure 5.1: Manual pages detailing procedures for cleaning the cooling system, including radiator drain valve and drain plug locations, and maintenance of the diesel fuel system, showing the fuel filler screen and sediment bowl.

5.2 Diesel Fuel System Maintenance

Maintaining a clean fuel system is critical for engine performance and longevity. This includes checking for water and sediment.

- Fuel Filler Screen: Regularly clean the fuel filler screen to prevent debris from entering the tank.

- Sediment Bowl: Check the sediment bowl for water and sediment every 50 hours of operation or weekly. Drain as necessary.

- Fuel Tank Drain Plugs: Periodically drain water and sediment from the fuel tank.

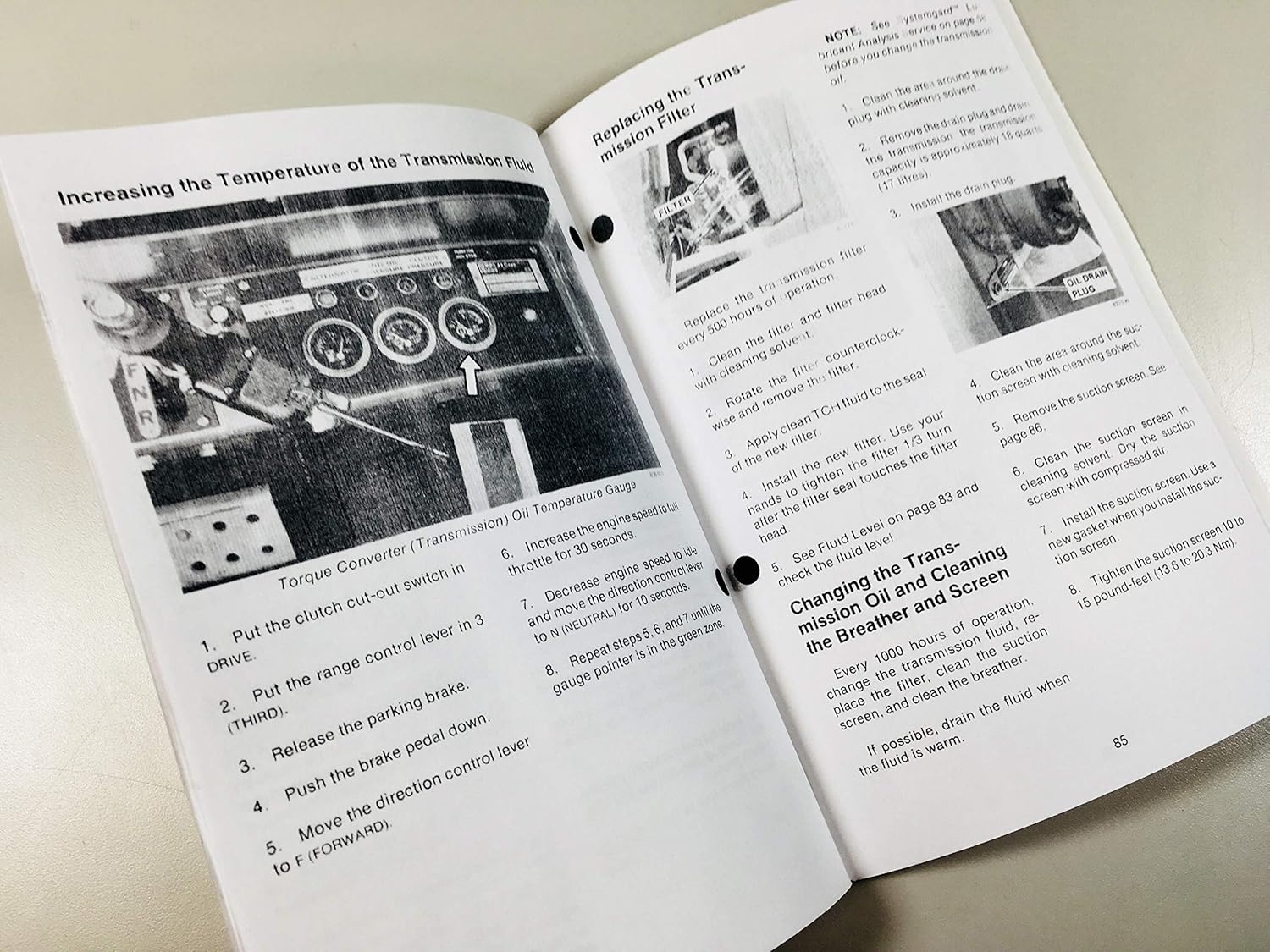

5.3 Transmission System Maintenance

Proper transmission maintenance ensures smooth operation and extends the life of the drivetrain components.

- Replacing the Transmission Filter: Replace the transmission filter every 500 hours of operation. Ensure the area is clean before removal and installation.

- Changing Transmission Oil and Cleaning Breather: Change the transmission fluid and clean the breather every 1000 hours of operation.

- Increasing Transmission Fluid Temperature: Procedures for warming up the transmission fluid for accurate level checks and optimal performance.

Figure 5.2: Manual pages illustrating the process of replacing the transmission filter and instructions for increasing the temperature of the transmission fluid, including a diagram of the torque converter oil temperature gauge.

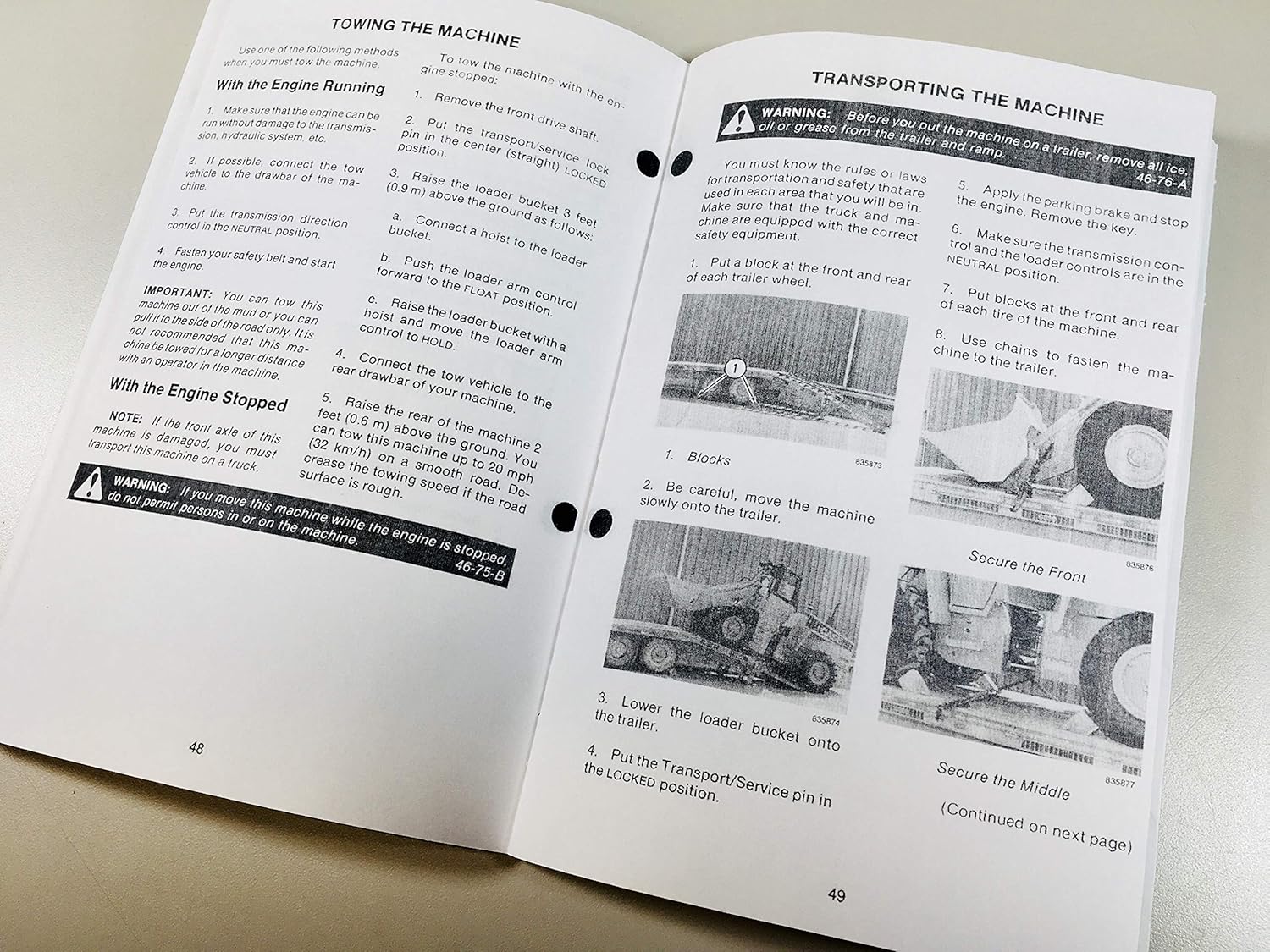

6. Transporting the Machine

This section provides critical instructions for safely towing and transporting the J I Case W11B Loader. Adhering to these procedures is essential to prevent damage to the machine and ensure safety during transit.

6.1 Towing the Machine

Instructions for towing the machine with the engine running or stopped, including procedures for preparing the machine, attaching towing equipment, and ensuring the transmission is in the correct position.

6.2 Transporting on a Trailer

Detailed steps for loading the W11B Loader onto a trailer, securing it properly, and preparing it for transport. This includes removing ice, oil, or grease, blocking wheels, and using chains to secure the machine.

Figure 6.1: Manual pages illustrating the procedures for towing the machine, including steps for connecting to a tow vehicle, and transporting the machine on a trailer, showing how to block wheels and secure the loader with chains.

7. Specifications

This section provides detailed technical specifications for the J I Case W11B Loader, covering key components such as the engine, cooling system, electrical system, and transmission, along with operating data and dimensions.

Figure 7.1: Manual pages displaying comprehensive technical specifications for the J I Case W11B Loader, including engine details, cooling system parameters, electrical system voltage, transmission type, and operating data with dimensional diagrams.

7.1 Engine Specifications

- Make and Model: Case

- Bore and Stroke: 4.02 in. x 4.72 in. (102 mm x 120 mm)

- Displacement: 239 cu. in. (3.9 liters)

- Horsepower: 73 hp (54 kW) at 2200 rpm (with turbocharger)

- Idle Speed: 700 rpm (no load)

7.2 Cooling System Specifications

- Radiator Cap Pressure: 15 psi (103 kPa)

- Thermostat Opening Range: 175°F to 192°F (80°C to 89°C)

7.3 Electrical System Specifications

- Type of System: 12 volt, negative ground

- Battery: 12 volt

- Alternator: 12 volt

7.4 Transmission Specifications

- Make and Model: Clark 1.2 HR 1800-19

- Type: Powershift with three speeds forward and three speeds in reverse

7.5 Operating Data and Dimensions

This section includes diagrams and data for the overall dimensions and operating characteristics of the W11B Loader, crucial for transport and operational planning.

8. Troubleshooting

This section typically provides guidance on identifying and resolving common operational issues that may arise with the J I Case W11B Loader. While specific troubleshooting charts are not detailed here, the full manual contains comprehensive diagnostic steps for various systems, including engine, hydraulic, and electrical problems.

For any issues, always refer to the detailed troubleshooting guides within the complete manual. If a problem persists, contact a qualified service technician.

9. Warranty and Support

Information regarding the warranty coverage for the J I Case W11B Loader and details on how to obtain technical support or replacement parts would typically be found in this section of the original manual. As this is a reproduction manual, specific warranty details for the machine itself are not included here.

For warranty claims or technical assistance related to the J I Case W11B Loader, please refer to the original purchase documentation or contact an authorized Case dealer or service center.