1. Product Overview

The Polyvance Stainless Steel Reinforcing Mesh is designed to enhance the strength and durability of thermoplastic repairs. This mesh is specifically engineered for use with FiberFlex rod and is suitable for various thermoplastic applications. Its stainless steel composition provides superior strength compared to standard aluminum wire screens.

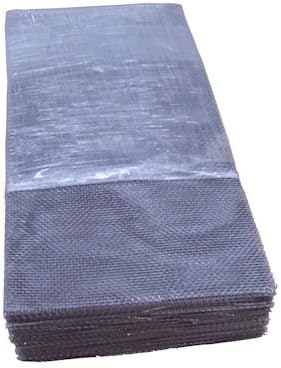

Image 1.1: A stack of Polyvance Stainless Steel Reinforcing Mesh sheets, highlighting their metallic appearance and woven structure.

Each pack contains 100 sheets of mesh, with each sheet measuring 5 inches (12.7 cm) by 10 inches (25 cm). This product is ideal for reinforcing tears that extend to the edge of plastic components, fabricating tabs, filling holes, and providing general reinforcement in any meltable plastic material.

Key Features:

- Five times stronger than typical aluminum window screen.

- Constructed from durable stainless steel.

- Each sheet measures 10 inches by 5 inches.

- Supplied in packs of 100 sheets.

- Versatile for fabricating tabs, filling holes, and general reinforcement.

2. Setup and Preparation

Before beginning any repair, ensure the plastic surface is clean, dry, and free of contaminants such as grease, oil, or dirt. Proper surface preparation is crucial for optimal adhesion and repair strength.

Materials Required:

- Polyvance Stainless Steel Reinforcing Mesh (Model 2045-100)

- FiberFlex rod (recommended for use with this mesh)

- Plastic welding equipment (e.g., hot air welder, nitrogen plastic welder)

- Safety glasses and gloves

- Cleaning agents (e.g., plastic cleaner, isopropyl alcohol)

Cut the reinforcing mesh to the desired size and shape using appropriate cutting tools. The mesh should extend slightly beyond the damaged area to provide adequate reinforcement.

3. Operating Instructions

The stainless steel reinforcing mesh acts similarly to rebar in concrete, significantly increasing the structural integrity of plastic repairs. It is particularly effective when repairing tears that reach the edge of a plastic component.

Application Steps:

- Prepare the Damaged Area: Clean the plastic surface thoroughly. If repairing a crack or tear, align the edges as closely as possible.

- Position the Mesh: Place the cut piece of reinforcing mesh over the prepared area. For tears extending to an edge, ensure the mesh covers the entire damaged section and slightly beyond.

- Embed the Mesh: Using a plastic welding tool (e.g., hot air welder), gently heat the plastic surface and the mesh. Carefully press the mesh into the molten plastic until it is fully embedded. Ensure the mesh is flush with or slightly below the surface.

- Apply FiberFlex Rod: Once the mesh is embedded, apply FiberFlex rod over the mesh and surrounding plastic using your plastic welding equipment. This creates a strong, reinforced bond.

- Fabricating Tabs or Filling Holes: For fabricating new tabs or filling larger holes, shape the mesh to the desired form. Embed it into the plastic as described above, then build up the area with FiberFlex rod or other suitable plastic filler.

- Finishing: Allow the repair to cool completely. The area can then be sanded, shaped, and painted as needed.

Image 3.1: Polyvance Stainless Steel Reinforcing Mesh as supplied in its packaging, ready for use.

4. Care and Maintenance

The Polyvance Stainless Steel Reinforcing Mesh itself requires minimal maintenance due to its durable stainless steel construction. However, proper storage and handling are recommended to ensure its longevity and effectiveness.

- Storage: Store unused mesh sheets in a dry, clean environment, away from corrosive chemicals or extreme temperatures. Keep them in their original packaging to prevent damage or contamination.

- Handling: Handle mesh sheets with care to avoid bending or deforming them, which could affect their structural integrity during application.

- Cleaning: If mesh sheets become dusty or dirty before use, gently wipe them with a clean, dry cloth. Avoid using harsh chemicals that could compromise the material.

5. Troubleshooting Common Issues

While the reinforcing mesh is designed for straightforward application, certain issues may arise during the repair process. Here are some common concerns and their potential solutions:

- Mesh Not Embedding Properly:

- Ensure the plastic welding tool is at the correct temperature for the specific thermoplastic being repaired.

- Apply even pressure when embedding the mesh.

- Verify the plastic surface is clean and free of any barriers to melting.

- Weak Repair After Cooling:

- Confirm that the mesh was fully embedded and covered by the FiberFlex rod.

- Ensure adequate penetration of the FiberFlex rod into the base plastic.

- Allow sufficient cooling time before stressing the repair.

- Mesh Protruding from Surface:

- This indicates the mesh was not fully embedded. Reheat the area carefully and gently press the mesh further into the plastic.

- Ensure the mesh is flush or slightly below the surface before applying filler rod.

For persistent issues or complex repairs, consult professional plastic repair guides or contact Polyvance customer support.

6. Product Specifications

| Attribute | Detail |

|---|---|

| Manufacturer | Polyvance |

| Brand | Polyvance |

| Model Number | 2045-100 |

| Item Weight | 4.05 pounds |

| Product Dimensions | 10.25 x 1.5 x 5.25 inches |

| Material | Stainless Steel |

| Sheet Dimensions | 5 inches (12.7 cm) x 10 inches (25 cm) |

| Quantity per Pack | 100 sheets |

| ASIN | B01JZQC9LM |

| Date First Available | August 8, 2016 |

7. Warranty and Support

For specific warranty information regarding the Polyvance Stainless Steel Reinforcing Mesh, please refer to the terms and conditions provided at the time of purchase or contact Polyvance directly.

Polyvance is committed to providing high-quality plastic repair products and support. If you have any questions, require technical assistance, or need further guidance on using this product, please reach out to Polyvance customer service.

You can find more information and contact details on the official Polyvance website or through their Amazon store: Polyvance Amazon Store.