Introduction

This manual provides essential information for the safe and efficient operation, installation, and maintenance of the Allen-Bradley PowerFlex 70 Variable Frequency Drive (VFD), model 20AC015A0AYNANNN. Please read this manual thoroughly before attempting to install, operate, or service the drive. Retain this manual for future reference.

The PowerFlex 70 VFD is designed to control the speed and torque of AC induction motors, offering precise control and energy efficiency in various industrial applications. This specific model is rated for 7.5 kW at 400V.

Safety Information

WARNING: This equipment contains high voltage. Only qualified personnel should install, operate, or maintain this device. Failure to observe safety precautions can result in severe injury or death.

- Always disconnect power before working on the drive or motor.

- Wait for capacitors to discharge completely before touching any components.

- Ensure proper grounding of the drive and motor.

- Follow all local and national electrical codes.

- Do not operate the drive with covers removed.

Setup and Installation

Proper installation is crucial for the reliable operation of the PowerFlex 70 VFD. Refer to the detailed wiring diagrams provided with the product for specific connections.

Mounting

Mount the drive vertically on a flat, stable surface. Ensure adequate clearance for cooling airflow. Avoid mounting in direct sunlight or areas with excessive vibration, dust, or corrosive gases.

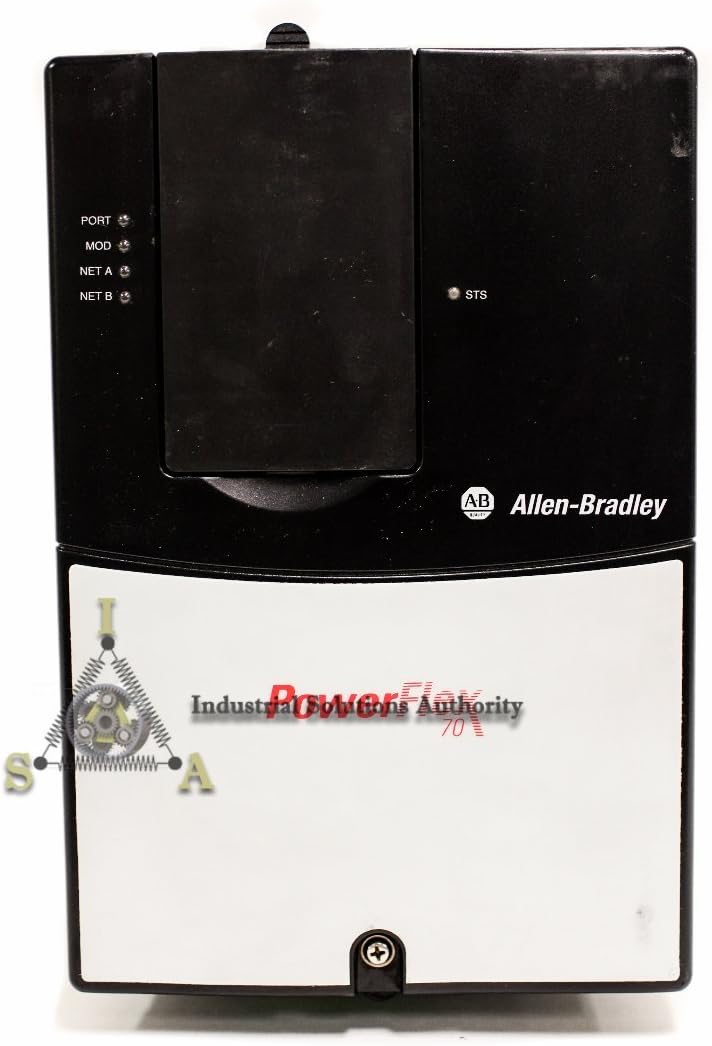

Figure 1: Front-right view of the Allen-Bradley PowerFlex 70 VFD, showing the main casing and ventilation grilles.

Wiring

- Power Input: Connect the incoming AC power to the L1, L2, L3 terminals. Ensure the voltage matches the drive's rating (400V).

- Motor Output: Connect the motor leads to the T1, T2, T3 terminals.

- Grounding: Connect the protective earth ground to the designated ground terminal.

- Control Wiring: Connect control signals (e.g., start/stop, speed reference) to the appropriate control terminals. Refer to the wiring diagram for specific terminal assignments.

Figure 2: Front view of the PowerFlex 70 VFD, highlighting the control panel area with status indicators (PORT, MOD, NET A, NET B, STS).

Operating Instructions

After successful installation and wiring, the drive is ready for initial power-up and configuration.

Initial Power-Up

- Verify all wiring connections are secure and correct.

- Apply main power to the VFD.

- Observe the drive's display and status indicators. The drive should power on and display a ready state or a default parameter.

Parameter Configuration

The PowerFlex 70 VFD requires configuration of various parameters to match the motor and application requirements. Common parameters include:

- Motor Nameplate Data (Voltage, Current, Frequency, RPM, Power)

- Acceleration/Deceleration Times

- Minimum/Maximum Frequencies

- Control Mode (V/Hz, Sensorless Vector, etc.)

- Input/Output Terminal Assignments

Refer to the comprehensive programming manual for a complete list of parameters and their functions. Parameters can typically be set via the drive's keypad or through communication software.

Starting and Stopping the Motor

- Start: Initiate a run command via the keypad, digital input, or communication network.

- Speed Control: Adjust the motor speed using the speed reference input (e.g., analog input, potentiometer, or network command).

- Stop: Issue a stop command via the keypad, digital input, or communication network. The drive will decelerate the motor according to the programmed deceleration time.

Maintenance

Regular maintenance ensures the longevity and optimal performance of your PowerFlex 70 VFD.

- Cleaning: Periodically clean the drive's heat sinks and ventilation openings to prevent dust buildup, which can impede cooling. Use compressed air or a soft brush. Ensure power is disconnected before cleaning.

- Connections: Check all electrical connections for tightness. Loose connections can cause overheating and intermittent operation.

- Environmental Check: Ensure the operating environment remains within specified temperature and humidity limits.

- Capacitor Inspection: For drives in service for several years, consider having qualified personnel inspect the DC bus capacitors for signs of degradation.

Figure 3: Top-down view of the PowerFlex 70 VFD, showing the top surface and part of the cooling fins.

Troubleshooting

This section provides guidance for common issues. For detailed fault codes and advanced diagnostics, refer to the drive's programming manual.

| Symptom/Fault Code | Possible Cause | Corrective Action |

|---|---|---|

| Drive does not power on | No input power; Blown fuse; Incorrect wiring | Check input power supply; Inspect fuses; Verify wiring connections. |

| Motor does not run | No run command; Incorrect parameter settings; Motor fault | Verify run command signal; Check motor parameters; Inspect motor for damage. |

| Overcurrent fault | Motor overload; Short circuit; Rapid acceleration | Reduce load; Check motor and cables for shorts; Increase acceleration time. |

| Overvoltage fault | High input voltage; Rapid deceleration; Regenerative load | Check input voltage; Increase deceleration time; Consider a dynamic braking resistor. |

Figure 4: Bottom view of the PowerFlex 70 VFD, showing the base and mounting points, indicating its robust construction.

Specifications

Key technical specifications for the Allen-Bradley PowerFlex 70 VFD, model 20AC015A0AYNANNN:

- Model Number: 20AC015A0AYNANNN

- Manufacturer: Allen-Bradley

- Power Rating: 7.5 kW

- Input Voltage: 400V AC

- Product Dimensions: 16 x 16 x 16 inches (approximate)

- ASIN: B01FKCM8CU

- Date First Available: May 12, 2016

Warranty and Support

For warranty information, please refer to the documentation provided at the time of purchase or contact your authorized Allen-Bradley distributor. Technical support can be obtained through official Allen-Bradley channels or your product supplier.

For additional resources, including detailed programming manuals and software, visit the official Rockwell Automation website (parent company of Allen-Bradley).