1. Product Overview

This manual provides comprehensive instructions for the safe and efficient operation, maintenance, and electrical systems of the South Bend Nordic 15 geared head lathe. It covers essential information for setup, daily use, and routine servicing to ensure optimal performance and longevity of the machine.

2. Technical Data

This section provides technical specifications and general data for the South Bend Nordic 15 lathe.

- Model: Nordic 15 (also covers models 15, 15")

- Manual Bulletin: 7015

- Print Length: 91 pages (original manual)

- Language: English

- Type: Geared Head Lathe

3. Installation

Proper installation is crucial for the safe and accurate operation of the Nordic 15 lathe. This section outlines procedures for shipping, cleaning, foundation preparation, and leveling.

3.1 Shipping and Unpacking

Upon receipt, inspect the shipping crate for any signs of damage. Carefully unpack the lathe, ensuring all components are accounted for. Retain all packing materials until the machine is fully installed and tested.

3.2 Cleaning

Before operation, thoroughly clean all protective coatings and debris from the lathe's surfaces. Use a suitable degreaser and soft cloths. Pay particular attention to precision surfaces and moving parts.

3.3 Foundation and Leveling

The lathe must be installed on a solid, level foundation capable of supporting its weight and resisting vibration. Use precision leveling tools to ensure the bed is perfectly level in both longitudinal and cross directions. Adjust leveling screws as necessary.

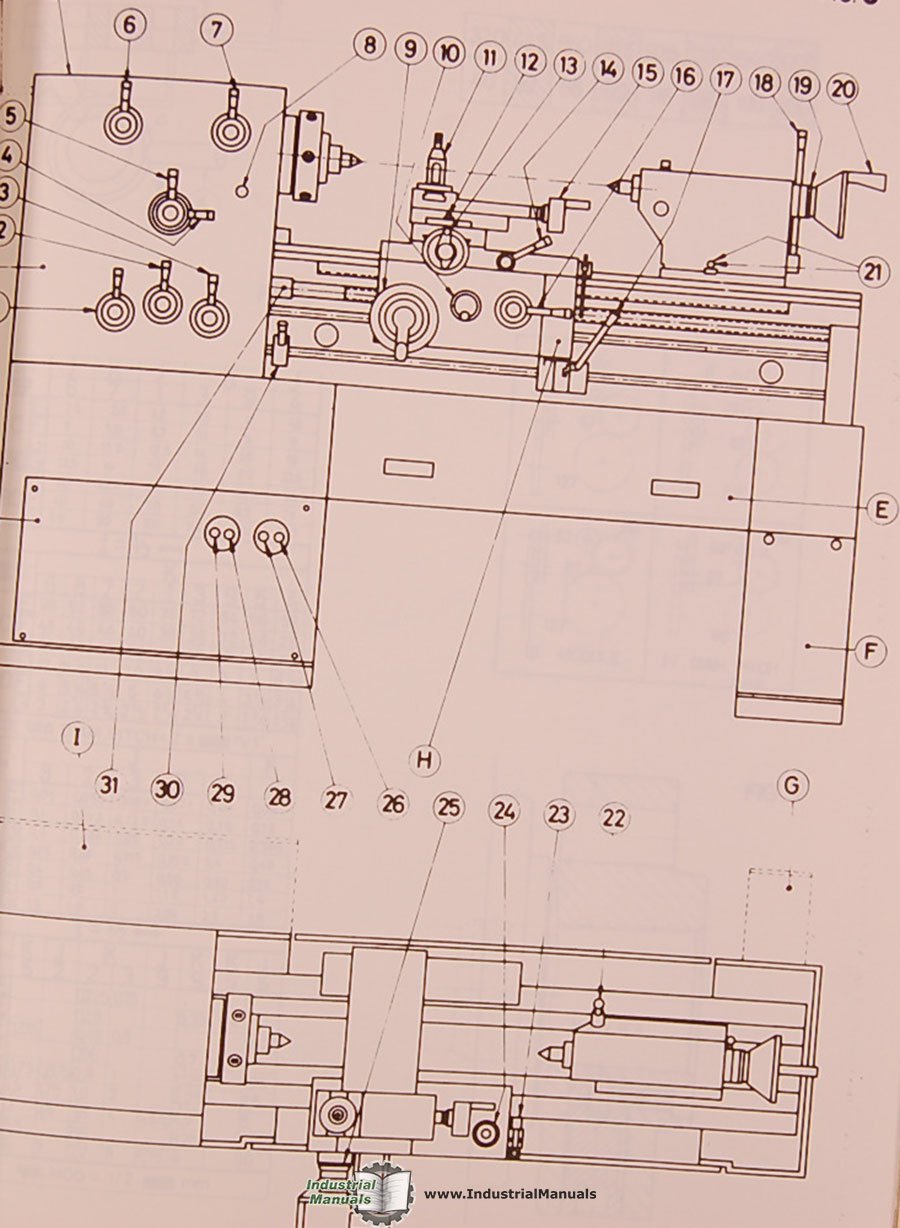

4. Control Table and Access

Familiarize yourself with the control panel and access points of the Nordic 15 lathe. This includes the main control table, inspection doors, and covers.

4.1 Control Table Layout

The control table provides access to speed selection levers, feed engagement levers, and emergency stop buttons. Refer to the machine's specific markings for detailed functions of each control.

4.2 Inspection Doors and Covers

Regularly inspect internal components by opening designated inspection doors and covers. Ensure these are securely closed before operating the machine to prevent injury and contamination.

5. Electrical Equipment

This section details the electrical connection requirements and wiring diagrams for the South Bend Nordic 15 lathe. All electrical work must be performed by a qualified electrician in accordance with local codes and regulations.

5.1 Connection

Ensure the lathe is connected to a power supply that matches the voltage and phase requirements specified on the machine's nameplate. Proper grounding is essential for safety.

5.2 Electrical Wiring Diagrams

Detailed electrical wiring diagrams are provided within the full manual to assist with installation, troubleshooting, and maintenance of the electrical system. These diagrams illustrate the connections for motors, controls, and safety interlocks.

6. Operating the Lathe

This section covers the fundamental procedures for operating the South Bend Nordic 15 lathe, including startup, speed and feed selection, and engaging feed motions.

6.1 Start-up and Running In

Before starting, ensure all safety guards are in place and the workpiece is securely mounted. Follow the recommended start-up sequence, allowing the machine to run briefly at low speeds to ensure proper lubrication and function.

6.2 Starting, Stopping, and Reversing Direction of Rotation

Use the designated controls to start and stop the spindle. The direction of rotation can be reversed using the appropriate lever or switch, typically located on the headstock or control panel. Always ensure the spindle is fully stopped before changing direction.

6.3 Selecting Speed and Feed

The Nordic 15 offers a range of speeds and feeds. Consult the speed and feed charts, usually located on the headstock, to select appropriate settings for your material and tooling. Adjust levers on the headstock and gearbox to achieve the desired speed and feed rate.

6.4 Longitudinal or Cross Feed Motion

Engage the longitudinal feed for cutting along the length of the workpiece or the cross feed for facing operations. Ensure only one feed motion is engaged at a time unless specifically required for a combined operation. Use the feed engagement levers on the apron.

6.5 How to Use Thread Chasing Dial

The thread chasing dial is essential for cutting threads accurately. It indicates when to engage the half-nuts to ensure the cutting tool re-enters the existing thread groove correctly. Follow the specific instructions for your thread pitch and lead screw combination.

7. Maintenance

Regular maintenance is vital for the longevity and precision of your South Bend Nordic 15 lathe. This section covers adjustments, dismantling procedures, and lubrication.

7.1 Adjustments and Dismantling

Periodically inspect and adjust components such as tightening belts, headstock spindle bearings, feed and gear box, leadscrew, saddle and slides, and the tailstock. Specific procedures for dismantling parts for repair or replacement are detailed in the full manual.

- Tightening Belts: Ensure proper belt tension for efficient power transmission.

- Headstock Spindle Bearings: Check for play and adjust according to specifications.

- Feed and Gear Box: Inspect for wear and proper engagement of gears.

- Leadscrew: Clean and lubricate the leadscrew regularly; check for backlash.

- Saddle and Slides: Adjust gibs to eliminate play while allowing smooth movement.

- Tailstock: Ensure tailstock alignment and proper clamping.

- Chuck: Inspect chuck jaws for wear and proper gripping.

7.2 Lubrication

Proper lubrication is critical. Refer to the lubrication chart in the full manual for recommended lubricants, lubrication points, and frequency. Regularly check oil levels and replenish as needed.

8. Troubleshooting

This section provides general guidance for common issues that may arise during the operation of the Nordic 15 lathe. For detailed troubleshooting steps, refer to the comprehensive manual.

- Machine not starting: Check power connection, emergency stop button, and circuit breakers.

- Excessive vibration: Inspect workpiece mounting, tool setup, and machine leveling.

- Poor surface finish: Verify tool sharpness, correct speed/feed, and machine rigidity.

- Feed mechanism not engaging: Check for obstructions, proper lever engagement, and lubrication.

- Unusual noises: Investigate potential issues with bearings, gears, or motor. Discontinue operation immediately if severe noise occurs.

9. Warranty and Support

Information regarding product warranty and customer support for the South Bend Nordic 15 lathe is not available within this specific manual extract. Please refer to your purchase documentation or contact South Bend directly for warranty details, technical assistance, and authorized service centers.