1. Introduction

This manual provides essential information for the safe and efficient operation of the Endress Hauser Cerabar PMC71 pressure transmitter. The Cerabar PMC71 is a highly reliable and robust device designed for precise pressure measurement in various industrial applications. It is engineered to deliver accurate and stable readings, ensuring optimal process control and monitoring. Please read this manual thoroughly before installation, operation, or maintenance to ensure proper handling and to prevent damage or injury.

2. Safety Information

Safety is paramount when working with industrial equipment. Adhere to all local and national safety regulations, as well as company-specific safety procedures.

- Installation, commissioning, and maintenance must only be performed by qualified and authorized personnel.

- Ensure the power supply is disconnected before performing any installation or maintenance work.

- Wear appropriate personal protective equipment (PPE) at all times.

- Be aware of potential hazards such as high pressure, electrical shock, and moving parts.

- Do not modify the device in any way. Unauthorized modifications can compromise safety and performance.

- Protect the device from extreme temperatures, vibrations, and corrosive environments unless specifically designed for such conditions.

3. Product Overview

The Endress Hauser Cerabar PMC71 is a robust pressure transmitter designed for demanding industrial environments. It typically features a durable housing, a process connection for pressure measurement, and an electrical connection for power and signal output.

Figure 3.1: Front view of the Endress Hauser Cerabar PMC71 pressure transmitter. This image shows the robust metallic housing, the display window, and the process connection flange at the bottom.

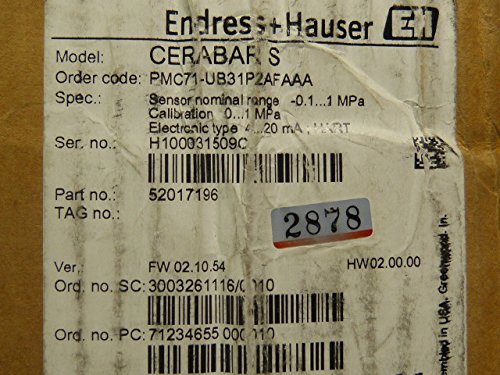

Figure 3.2: Close-up view of the product label on the Endress Hauser Cerabar PMC71 packaging. The label displays critical information such as the model (CERABAR S), order code (PMC71-UB31P2AFAAA), sensor nominal range, calibration details, serial number (H100031509C), and part number (52017196).

The device is typically shipped in protective packaging to ensure its integrity during transit.

Figure 3.3: Original packaging for the Endress Hauser Cerabar PMC71. The cardboard box features the Endress+Hauser logo and shipping labels, indicating careful handling for delicate instruments.

4. Setup and Installation

Proper installation is crucial for the accurate and reliable operation of the Cerabar PMC71.

4.1 Unpacking

- Carefully remove the device from its packaging.

- Inspect the device for any visible damage that may have occurred during shipping.

- Verify that all components listed in the packing slip are present.

4.2 Mounting

Mount the pressure transmitter securely in a location that is easily accessible for maintenance and where it is protected from excessive vibration and extreme environmental conditions. Ensure the mounting position allows for proper drainage if condensation is a concern.

4.3 Electrical Connection

Connect the device to the appropriate power supply and signal lines according to the wiring diagram provided in the full technical documentation. Ensure all connections are secure and comply with local electrical codes.

4.4 Process Connection

Connect the pressure transmitter to the process line using the appropriate flange or thread connection. Ensure a leak-free seal. Refer to the device's specifications for compatible process media and pressure ranges.

5. Operating Instructions

Once installed and powered, the Cerabar PMC71 begins measuring pressure.

5.1 Power On

Apply power to the device. The display (if present) should illuminate, and the device will initiate its self-test routine.

5.2 Basic Operation

The Cerabar PMC71 is designed for continuous pressure measurement. The measured pressure value is typically transmitted as an analog signal (e.g., 4-20 mA) or digital signal (e.g., HART) to a control system. For detailed configuration and calibration, refer to the comprehensive technical documentation or contact Endress Hauser support.

6. Maintenance

Regular maintenance ensures the longevity and accuracy of the Cerabar PMC71.

6.1 Routine Checks

- Periodically inspect the device for any signs of physical damage, corrosion, or leaks.

- Ensure all electrical and process connections remain secure.

- Keep the device clean, especially the display window and process connection area. Use a soft, damp cloth for cleaning; avoid abrasive cleaners.

6.2 Calibration

Depending on application requirements and industry standards, periodic calibration of the pressure transmitter may be necessary to maintain measurement accuracy. Refer to Endress Hauser's calibration guidelines or consult a certified calibration service.

7. Troubleshooting

This section provides guidance for common issues. For complex problems, contact technical support.

| Problem | Possible Cause | Solution |

|---|---|---|

| No display/No power | No power supply; Loose electrical connection; Blown fuse | Check power supply; Secure electrical connections; Replace fuse if necessary (by qualified personnel) |

| Incorrect pressure reading | Sensor clogged; Incorrect calibration; Process connection leak; Incorrect configuration | Inspect and clean sensor; Perform calibration; Check process connection for leaks; Verify configuration settings |

| Unstable reading | Vibration; Process fluctuations; Electrical interference | Reduce vibration if possible; Analyze process stability; Check for proper grounding and shielding |

If the problem persists after attempting these solutions, refer to the detailed troubleshooting guide in the full technical documentation or contact Endress Hauser customer support.

8. Specifications

Key technical specifications for the Endress Hauser Cerabar PMC71 (Model 52017196):

- Brand: Endress Hauser

- Model: Cerabar PMC71

- Manufacturer Reference: 52017196

- ASIN: B00TGGFXRO

- Product Dimensions: 51 x 36 x 36 cm

- Item Weight: 7 Kilograms

- Date First Available: March 1, 2017

9. Warranty and Support

For detailed information regarding the warranty period and terms for your Endress Hauser Cerabar PMC71, please refer to the documentation provided with your purchase or contact your authorized Endress Hauser distributor.

For technical support, service, or to obtain additional documentation, please contact Endress Hauser directly through their official website or your local sales representative.

Endress Hauser Official Website: www.endress.com