1. Introduction

This manual provides essential information for the safe and efficient installation, operation, and maintenance of the Festo CPE14-M1BH-5L-1/8 Solenoid Valve. Please read this manual thoroughly before using the product to ensure proper function and to prevent damage or injury. Keep this manual for future reference.

2. Product Overview

The Festo CPE14-M1BH-5L-1/8 is a high-performance solenoid valve designed for pneumatic applications. It is engineered for reliability and precision in controlling air flow within industrial systems. This valve features a compact design and robust construction, making it suitable for various automation tasks.

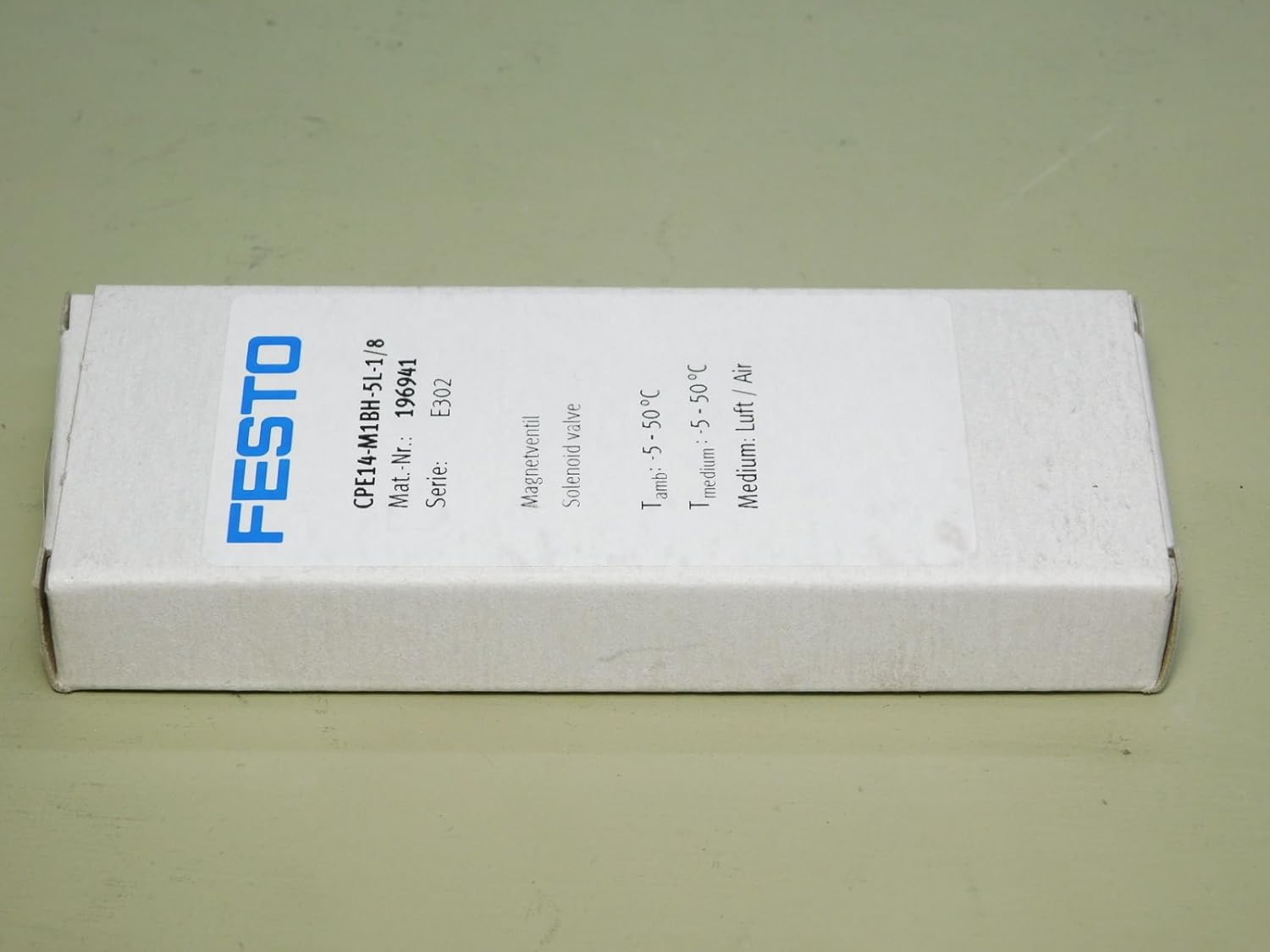

Figure 2.1: Festo CPE14-M1BH-5L-1/8 Solenoid Valve packaging box. This image displays the packaging box for the Festo CPE14-M1BH-5L-1/8 Solenoid Valve, showing the model number, material number (196941), series (E302), and operating conditions such as ambient and medium temperature ranges (-5 to 50°C) and medium type (air).

2.1 Key Features

- Compact and robust design

- Suitable for pneumatic applications

- Reliable air flow control

- Durable construction with Brass and Stainless Steel components

3. Safety Information

WARNING: Failure to follow these safety instructions may result in serious injury or equipment damage.

- Always disconnect power and depressurize the system before performing any installation, maintenance, or troubleshooting.

- Ensure that the operating pressure and temperature are within the specified limits for the valve.

- Only qualified personnel should install, operate, and maintain this device.

- Use appropriate personal protective equipment (PPE) during installation and maintenance.

- Do not modify the valve in any way. Use only genuine Festo replacement parts.

- Protect the valve from excessive vibration, impact, and corrosive environments.

4. Setup and Installation

4.1 Unpacking

Carefully remove the valve from its packaging. Inspect the valve for any visible damage that may have occurred during shipping. Do not install a damaged valve.

4.2 Mounting

- Select a mounting location that is stable, free from excessive vibration, and allows for easy access for connection and maintenance.

- Ensure the valve is mounted in an orientation that allows for proper drainage if condensation is a concern.

- Secure the valve using appropriate fasteners to prevent movement during operation.

4.3 Pneumatic Connections

- Ensure the air supply is clean, dry, and filtered to prevent contamination of the valve.

- Connect the pneumatic lines to the valve's inlet and outlet ports. Refer to the valve markings for port identification.

- Use appropriate thread sealant on all connections to ensure a leak-free seal.

- Verify that all connections are tight but do not overtighten, which could damage the valve or fittings.

4.4 Electrical Connections

Connect the electrical supply to the solenoid coil according to local electrical codes and the valve's specifications. Ensure the voltage and frequency match the requirements of the solenoid. Improper electrical connections can damage the valve or pose a safety hazard.

5. Operating Instructions

5.1 Initial Startup

- Before applying pressure, ensure all pneumatic and electrical connections are secure.

- Slowly introduce air pressure into the system, checking for any leaks.

- Apply electrical power to the solenoid coil.

- Test the valve's operation by actuating it several times to confirm proper switching.

5.2 Normal Operation

The Festo CPE14-M1BH-5L-1/8 valve operates by receiving an electrical signal to energize its solenoid coil, which then shifts the internal mechanism to control the flow of air. The valve is designed for continuous duty within its specified operating parameters.

Monitor system pressure and temperature to ensure they remain within the valve's rated limits (Maximum Operating Pressure: 8 Bars, Medium Temperature: -5 to 50°C).

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your Festo CPE14-M1BH-5L-1/8 Solenoid Valve. Always depressurize the system and disconnect power before performing any maintenance.

6.1 Routine Checks

- Periodically check for air leaks around connections and valve body. Use a leak detection spray if necessary.

- Inspect electrical connections for signs of wear, corrosion, or loose wiring.

- Ensure the air supply is clean and dry. Replace air filters as recommended by your system's manufacturer.

6.2 Cleaning

Clean the exterior of the valve with a soft, damp cloth. Do not use harsh chemicals or abrasive cleaners that could damage the valve's materials.

6.3 Component Replacement

Internal components of the valve are generally not user-serviceable. If the valve malfunctions, it is typically replaced as a complete unit. Contact Festo support or an authorized distributor for replacement parts or service.

7. Troubleshooting

This section provides guidance for common issues encountered with the Festo CPE14-M1BH-5L-1/8 Solenoid Valve. For problems not listed here, contact technical support.

| Problem | Possible Cause | Solution |

|---|---|---|

| Valve does not actuate |

|

|

| Air leakage from valve |

|

|

| Valve operates sluggishly |

|

|

8. Technical Specifications

The following table outlines the key technical specifications for the Festo CPE14-M1BH-5L-1/8 Solenoid Valve:

| Specification | Value |

|---|---|

| Model Number | CPE14-M1BH-5L-1/8 |

| Manufacturer | FESTO |

| Material | Brass, Stainless Steel |

| Product Dimensions (L x W x H) | 9.06 x 6.3 x 7.09 inches |

| Weight | 4.4 Pounds |

| Maximum Operating Pressure | 8 Bars |

| Number of Ports | 2 |

| Inlet Connection Type | Bar |

| Specification Met | ASME, ANSI, ASTM |

| Date First Available | December 15, 2014 |

9. Warranty and Support

9.1 Warranty Information

Festo products are manufactured to high-quality standards. For specific warranty terms and conditions applicable to the CPE14-M1BH-5L-1/8 Solenoid Valve, please refer to the official Festo warranty policy available on their website or contact your local Festo representative. Keep your purchase receipt as proof of purchase.

9.2 Technical Support

If you encounter issues that cannot be resolved using the troubleshooting guide, or require further technical assistance, please contact Festo customer support. Provide the model number (CPE14-M1BH-5L-1/8) and material number (196941) when seeking support to expedite the process.

For contact information, please visit the official Festo website: www.festo.com