Introduction

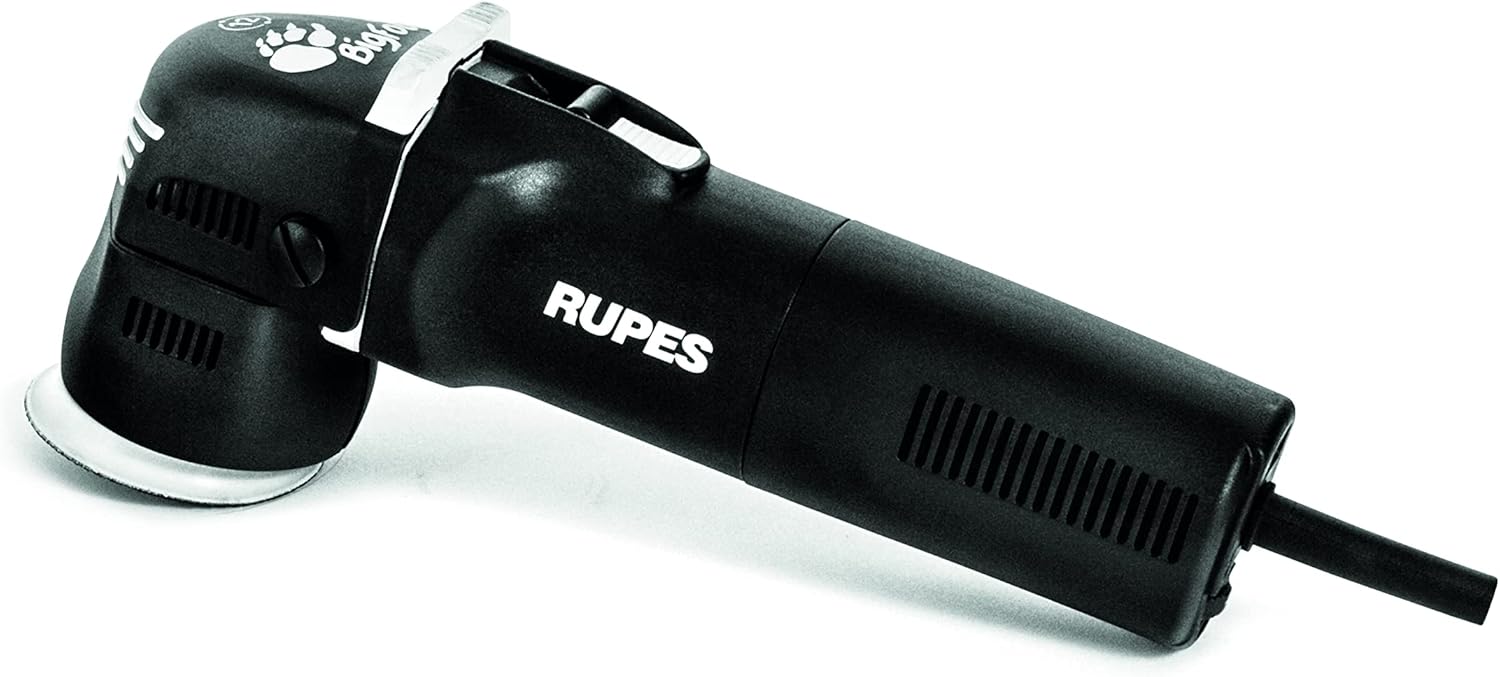

The RUPES LHR 75E Random Orbital Polisher is engineered for precision detailing, allowing users to achieve perfect results even in challenging areas. Its ergonomic design and 12 mm orbit are ideal for spot repair operations and intricate surfaces like mudguards and front panels, ensuring comfortable handling and accuracy in polishing tasks.

Key features include:

- Ergonomically perfect shape with non-slip rubber inserts for comfort and control.

- Non-slip rubber on/off lever for controlled soft start.

- Electronic speed control module for easy adjustment during operation.

- Powerful 400 watt motor with an 18AWG USA polarized 4mt plug.

- Made in Italy, ensuring high-quality craftsmanship.

What's in the Box

Upon unboxing your RUPES LHR75E Random Orbital Polisher, you should find the following components:

- RUPES LHR75E Polisher Unit

- Backing Plate

Setup

Before operating your RUPES LHR75E polisher, ensure proper setup for safety and optimal performance.

- Inspect the Unit: Check the polisher for any visible damage or loose parts. Ensure the power cord is intact.

- Attach Backing Plate: Securely attach the appropriate backing plate to the polisher's spindle.

- Select and Attach Polishing Pad: Choose the correct polishing pad (foam or microfiber) for your task. Ensure it is clean and free of debris. Align the pad with the backing plate and firmly press it into place using the hook-and-loop system.

- Connect Power: Plug the 18AWG USA polarized 4mt power cord into a suitable electrical outlet.

Figure 1: RUPES LHR75E Polisher with attached power cord.

Figure 2: Top view of the RUPES LHR75E, highlighting the 'Bigfoot mini 12' branding and ergonomic design.

Operating Instructions

Follow these steps for effective and safe operation of your RUPES LHR75E polisher.

- Prepare Surface: Ensure the vehicle surface is clean, dry, and free of contaminants. Mask off any trim or areas not to be polished.

- Apply Compound/Polish: Apply a small amount of polishing compound or polish directly onto the pad.

- Set Speed: Use the electronic speed control module to select the desired speed setting. Start with a lower speed to spread the product, then increase as needed for correction.

- Start Polishing: Place the pad flat on the surface before turning on the polisher. Use the non-slip rubber on/off lever for a controlled soft start.

- Technique: Work in small sections (e.g., 2x2 feet). Apply light to moderate pressure and move the polisher in overlapping passes (cross-hatch pattern). Maintain consistent speed and pressure.

- Wipe Off Residue: After polishing a section, turn off the polisher, lift it from the surface, and wipe off any residue with a clean microfiber towel.

Figure 3: Applying polishing compound to the pad before use.

Figure 4: Electronic speed control dial for precise adjustment.

Figure 5: Polishing a car panel with the RUPES LHR75E.

Figure 6: The compact size of the LHR75E allows for precise work on smaller, intricate areas like side mirrors.

Helpful Video Resources

Video 1: This video demonstrates the features and use of a mini random orbital polisher, similar in concept to the RUPES LHR75E, for detailing various car parts. (Note: This video features a Griot's Garage G8 Mini Random Orbital Polisher, not the RUPES LHR75E directly, but illustrates general mini polisher usage.)

Video 2: This video showcases a 3-inch mini random orbital car buffer polisher set in action, providing visual guidance on how such tools are used for car detailing. (Note: This video features an SPTA 3-inch mini polisher, not the RUPES LHR75E directly, but illustrates general mini polisher usage.)

Maintenance

Regular maintenance ensures the longevity and optimal performance of your RUPES LHR75E polisher.

- Clean Pads: After each use, clean polishing pads thoroughly to remove compound residue. Allow them to air dry completely.

- Wipe Down Polisher: Wipe the polisher body with a clean, damp cloth to remove any dust or polish splatter.

- Inspect Cord: Periodically check the power cord for cuts, fraying, or damage. Replace if necessary.

- Store Properly: Store the polisher in a clean, dry place, away from extreme temperatures and direct sunlight.

Troubleshooting

If you encounter issues with your RUPES LHR75E polisher, refer to the following common troubleshooting tips:

- Polisher Not Turning On:

- Ensure the power cord is securely plugged into a working outlet.

- Check the on/off lever for proper engagement.

- Excessive Vibration/Noise:

- Ensure the backing plate and polishing pad are securely attached and centered.

- Check the pad for uneven wear or damage. Replace if necessary.

- Poor Polishing Performance:

- Ensure the correct pad and compound are being used for the task.

- Adjust the speed setting as appropriate for the product and surface condition.

- Clean or replace clogged pads.

Specifications

| Feature | Detail |

|---|---|

| Brand | RUPES |

| Model | LHR75E#120/H6/US/STD |

| Power Source | Corded Electric |

| Maximum Power | 400 Watts |

| Item Weight | 6.1 Pounds |

| Product Dimensions | 15.6"D x 6.7"W x 6.4"H |

| Material | Alloy Steel, Metal |

| Color | Orange |

| Specific Uses | Automotive, Professional |

Warranty and Support

The RUPES LHR75E Random Orbital Polisher comes with a 1-year manufacturer's warranty. For warranty claims, technical support, or service inquiries, please refer to the contact information provided in your product packaging or visit the official RUPES website.