1. Introduction

This manual provides essential information for the proper installation, operation, and maintenance of your ACDelco GM Original Equipment 12654815 V-Ribbed Serpentine Belt. Designed and tested to rigorous General Motors standards, this serpentine belt is a critical component for the efficient operation of various engine accessories.

The V-ribbed design ensures a secure point of contact with pulleys, providing optimal traction for reliable performance. For safety and proper function, please read this manual thoroughly before installation or service.

2. Safety Information

Always observe the following safety precautions when working with automotive components:

- Wear appropriate personal protective equipment (PPE), including safety glasses and gloves.

- Ensure the engine is off and cooled down before attempting any work.

- Disconnect the battery to prevent accidental starting or electrical hazards.

- Refer to your vehicle's specific service manual for detailed instructions and torque specifications.

- Keep hands and clothing clear of moving parts when the engine is running.

- Dispose of old belts and other materials responsibly according to local regulations.

3. Product Overview

The ACDelco GM Original Equipment 12654815 V-Ribbed Serpentine Belt is designed to drive multiple peripheral devices in your vehicle's engine, such as the alternator, power steering pump, air conditioning compressor, and water pump, using a single belt. Its construction ensures durability and efficient power transfer.

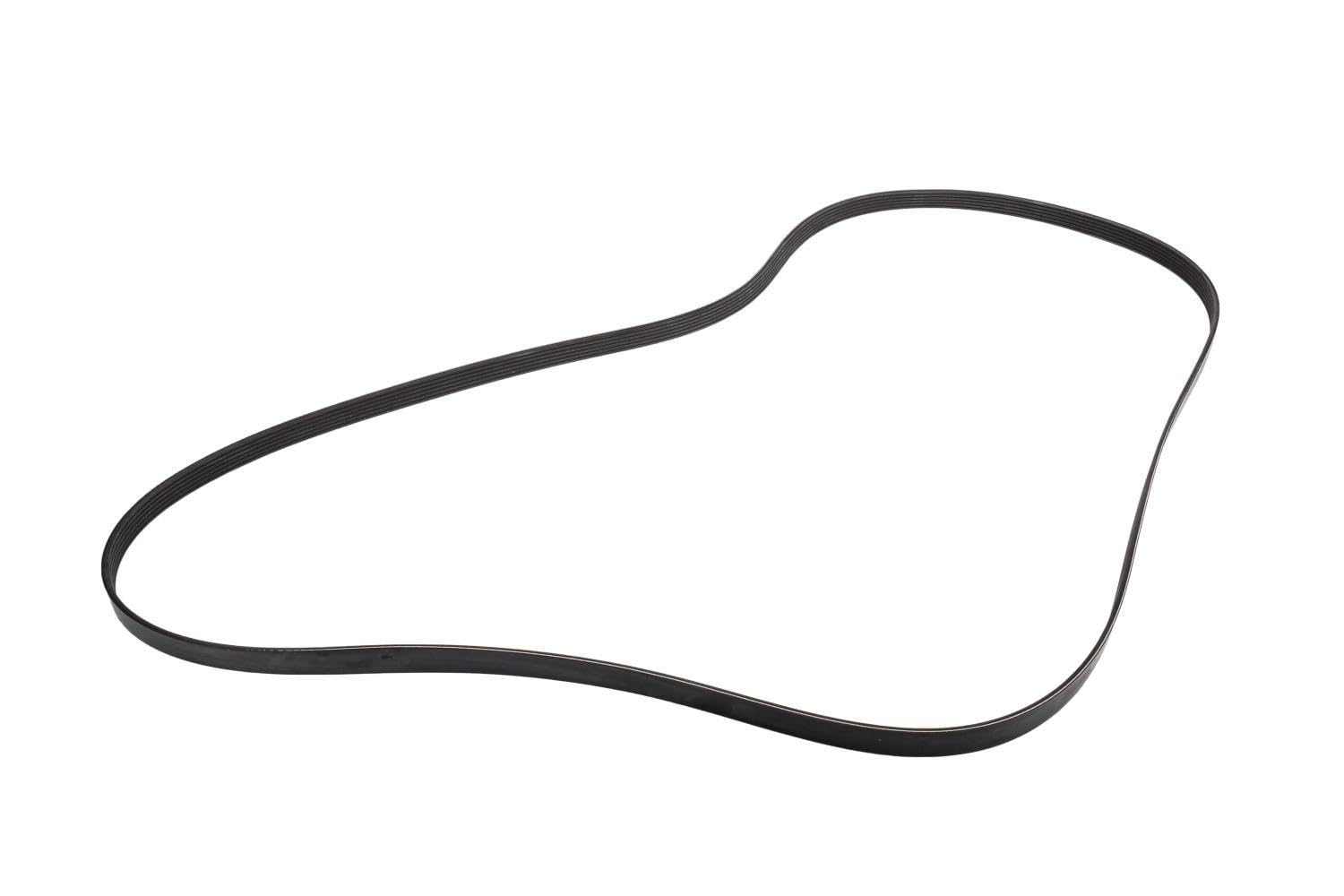

Figure 3.1: ACDelco GM Original Equipment V-Ribbed Serpentine Belt (Model 12654815).

Key features include:

- V-Ribbed Construction: Provides a secure grip on pulleys for efficient power transmission.

- GM Original Equipment: Engineered and validated by General Motors for optimal fit and performance in GM vehicles.

- Durability: Constructed from high-quality materials to withstand engine heat and stress.

4. Setup and Installation

Installation of a serpentine belt requires specific tools and knowledge. If you are not confident in your ability to perform this task, it is recommended to seek assistance from a qualified automotive technician.

4.1 Tools Required

- Serpentine belt tensioner tool (specific to your vehicle)

- Socket wrench set

- Gloves and safety glasses

- Diagram of the belt routing (usually found under the hood or in the vehicle service manual)

4.2 Installation Steps

- Preparation: Ensure the engine is off and cool. Disconnect the negative battery terminal. Locate the belt routing diagram.

- Relieve Tension: Using the serpentine belt tensioner tool, rotate the tensioner pulley to relieve tension on the old belt.

- Remove Old Belt: Carefully remove the old belt from all pulleys. Note its routing for reference.

- Inspect Pulleys: Check all pulleys for wear, damage, or excessive play. Replace any faulty pulleys before installing the new belt.

- Install New Belt: Route the new ACDelco 12654815 serpentine belt according to the diagram, ensuring it is correctly seated in all pulley grooves. Start with the smooth pulleys first, then the ribbed ones.

- Apply Tension: Once the belt is correctly routed, use the tensioner tool to rotate the tensioner pulley again, allowing the belt to slip over the final pulley (usually the tensioner itself). Slowly release the tensioner.

- Verify Installation: Double-check that the belt is properly seated on all pulleys and that there are no twists or misalignments.

- Final Steps: Reconnect the negative battery terminal. Start the engine and observe the belt for proper operation and any unusual noises.

Figure 4.1: Close-up view of the V-ribbed surface of the serpentine belt, showing the grooves that engage with engine pulleys.

5. Operating Considerations

Once installed, the serpentine belt operates continuously with the engine. Proper operation is indicated by smooth, quiet rotation without slipping or excessive noise. The belt's primary function is to transfer power from the crankshaft to various engine accessories.

- Initial Run-in: After installation, run the engine for a few minutes and then re-check the belt tension and seating on all pulleys.

- Normal Operation: The belt should run smoothly and quietly. Any squealing, chirping, or grinding noises may indicate a problem with the belt, tensioner, or an accessory pulley.

6. Maintenance

Regular inspection and maintenance are crucial for the longevity and reliable performance of your serpentine belt.

6.1 Inspection Schedule

Inspect the serpentine belt at every oil change or at least every 12,000 miles (20,000 km), or as recommended by your vehicle manufacturer.

6.2 What to Look For During Inspection

- Cracks: Small cracks across the ribs are normal with age, but deep or numerous cracks indicate replacement is due.

- Fraying/Shredding: Any signs of material fraying, shredding, or missing chunks require immediate replacement.

- Glazing: A shiny, hardened appearance on the belt ribs indicates glazing, which can lead to slipping.

- Contamination: Oil, grease, or coolant on the belt can cause degradation and slipping. Identify and fix leaks, then replace the belt.

- Rib Wear: Uneven wear or missing ribs.

- Tensioner Condition: Check the automatic tensioner for proper operation. It should maintain consistent tension. Look for excessive vibration or play.

Figure 6.1: An ACDelco serpentine belt, showing branding and part numbers, useful for identification during maintenance.

6.3 Cleaning

Avoid using belt dressings or cleaners, as these can damage the belt material. If the belt is contaminated, identify and fix the source of the contamination, then replace the belt.

7. Troubleshooting

Common issues related to serpentine belts and their potential solutions:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Squealing or Chirping Noise | Loose belt, worn belt, misaligned pulley, worn tensioner, contaminated belt. | Inspect belt for wear and tension. Check pulley alignment and tensioner function. Clean or replace belt if contaminated. |

| Belt Slipping | Insufficient tension, glazed belt, oil/coolant contamination, worn pulleys. | Check tensioner. Inspect belt for glazing or contamination. Replace worn components. |

| Cracked or Frayed Belt | Normal wear and tear, excessive heat, misaligned pulleys. | Replace the belt. Inspect pulleys for alignment and wear. |

| Loss of Power Steering/AC/Charging | Belt has broken or slipped off pulleys. | Immediately pull over safely. Inspect and replace belt if broken. Re-route if slipped. Address underlying cause (e.g., seized pulley). |

If troubleshooting steps do not resolve the issue, consult a certified automotive technician.

8. Specifications

The following specifications apply to the ACDelco GM Original Equipment 12654815 V-Ribbed Serpentine Belt:

- Part Number: 12654815

- Brand: ACDelco GM Original Equipment

- Belt Style: V-Ribbed

- Material: Engineered rubber compounds for durability and flexibility

- Color: Black

- Dimensions (Approximate): 6 x 3.31 x 1 inches (packaging)

- Weight (Approximate): 7.2 ounces

- Compatible Devices: Designed for specific GM vehicle applications (refer to vehicle service manual for exact fitment)

9. Warranty and Support

ACDelco GM Original Equipment parts are backed by General Motors. For specific warranty information, please refer to the warranty documentation included with your purchase or visit the official ACDelco website. Warranty terms and conditions may vary.

For technical support or further assistance, please contact ACDelco customer service or consult an authorized ACDelco service center. You can find more information and contact details on the ACDelco Store on Amazon or the official ACDelco website.